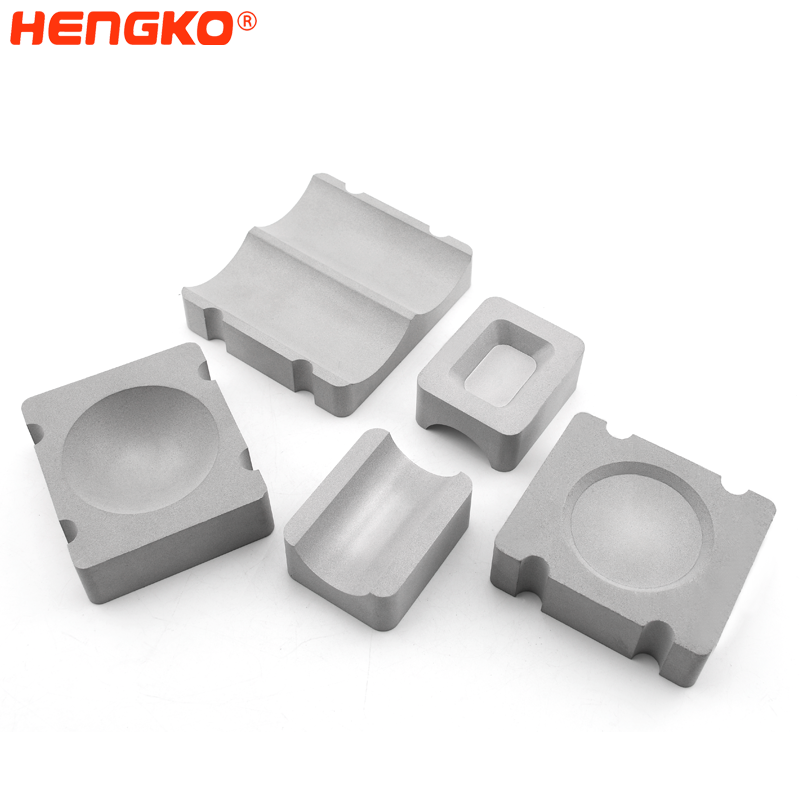

Custom Any Design Sintered Metal Filters

-

Custom Any Design Sintered Metal Filters

* Sintered Metal Filters

* Porous Metal Disc & Sheets

* Porous Metal Cups & Tubes

* Stainless Steel Mesh Filter

* Instrument Components

-

Temperature Humidity Probe / Sensor Housing

* Temperature And Humidity Probe

* OEM Temperature Humidity Probe

* Custom Relative Humidity Probe

* Long Probe of Humidity Sensor

* Humidity Monitor with LCD Display

-

Custom High-End Filtration Solution As Application

* Air Muffler Silencer

* Industrial Sparger Systems

* Air Diffusion Stone

* Explosion-Proof Gas Sensor

* High Purity Gas Filter

-

Industrial Temperature and Humidity Monitor & Sensor

* Temp Humidity Transmitter

* Handheld Humidity Meter

* Dew point Sensor / Monitor

IoT Temperature and Humidity Sensor Solution

OEM & Inquiry For Price List

As Your Porous Metal Filter and Industrial Humidity Sensor Solutions Partner, HENGKO, with Rich Experience in Design and Manufacturing Thousands of Applications, Create Highly Engineered Products to 100% Meet Your Project Needs. Tell Us More About Your Project, and We Are Pleasure Can Help You! Contact Us Today!

Get Instant Quotationexplore our Feature Products

Here Are Some Hot Sale Sintered Metal Filter Elements and Industry Humidity Monitor Products, With Factory Price, No Middle Man; 100% Warranty Service