-

High Quality Sintered Bronze Fuel Filter

Product Details Introducing our top-of-the-line Fuel Filter with Sintered Bronze Fuel Element - the perfect solution for anyone who is in need of a high-qual...

View Detail -

Sintered Copper Bronze Grounding Plate

Deters Electrolysis and Galvanic CorrosionReduces RF Interference and Improves Electronics Performance Better reception for your GPS devices, weather ...

View Detail -

Porous Metal Sintered Mini Cylinder

Porous metals are one of the many materials suitable for manufacturing bearings. Benefits of Sintered Mini Cylinder Powdered metals have a large numbe...

View Detail -

Acid and Alkali Resistant More Durable 316L Porous Stainless Steel Filter Sintered Filt...

Product Describe HENGKO biomedical filter is made of 316L metal powder sintered at high temperature, with a uniform porosity of 0.2-0.5 um, corrosion resista...

View Detail -

CEMS Online Smoke Analyzer Gas Sampling Probe 44.5mm*121mm a Unique Probe Design

Product Describe * Dust separation in the process * For dust concentrations above 3g/m3 * Large active surface * Long lifetime * Low differential pressur...

View Detail -

Porous metal filter tube for thermal management refining and specialty chemical | HENGKO

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

316L SS stainless steel metal sintered filters,Customized microporous nickel monel inco...

HENGKO's porous metal materials are produced through rigorous heat treatment of multilayer stainless steel wire mesh or 316L powder at high temperatures. Cus...

View Detail -

Candle type Sintered 316L stainless steel mesh filter reusable cartridge

HENGKO offers an extensive collection of stainless steel filter cartridges that are tailored for use in a broad range of industries, including petrochemicals...

View Detail -

Anti-corrosion Microns Powder Porous Sintered Metal Filter Cartridge For Filtration System

HENGKO creates porous filter tubes that offer versatility in design as they can be hollow or blind with a minimum wall thickness of 1mm. These products are c...

View Detail -

sintered porous metal filter material media , porosity 0.2 μm ~ 100 micron titanium mon...

At HENGKO, the process of creating their porous metal materials involves heat treating 316L powder material or multilayer stainless steel wire mesh at high t...

View Detail -

porous metal stainless steel cartridge filter for high pressure air purification solid ...

HENGKO manufactures its porous metal materials by heat treating 316L powder material or multilayer stainless steel wire mesh at elevated temperatures. Their ...

View Detail -

Skilled 0.2 to 120 microns micro porosity brass inconel monel 316 316L stainless steel ...

Porous metal is created by compressing powder metal into various shapes, which are then sinter-bonded to create a strong and inert structure. This versatile ...

View Detail -

Sintered Bronze Filters with OEM Specific Shape for Filtration

HENGKO could offer customers the possibility of manufacturing filters and porous bronze components with specific shapes. Each of these special applications r...

View Detail -

5 10 20 90 120 microns sintered porous metal bronze stainless steel 316L multi-purpose ...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Uniform strength sintered porous metal micron filter fluidizers bronze brass copper fil...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

sintered air filter medium spheric bronze filter element

HENGKO SINTERED BRONZE OIL FILTER is applied in sparging, sensor protection, gas, and liquid filtration, dampening, bulk handling and etc. which for the solu...

View Detail -

Flow control and fluid distribution sintered filter plate/sheet, powder sintered porous...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Porous metal sintered bronze brass filter uniaxial cylinders with one closed end with hex.

Product Description HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the charac...

View Detail -

Porous metal sintered porous bronze filter plates/sheet for flow and sound control

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Medical chemical liquid oil and gases 3um-90 microns powder porous all-metal steam sint...

HENGKO porous filter tubes can be hollow or blind and have a minimum wall thickness of 1 mm. They are made by isostatic compaction of powder in a flexible mo...

View Detail

What is Sintered Powder Metal Filter and Main Features

Sintered powder metal filters are a type of filter made by sintering, or heating, a mixture of metal powders

until they bond together to form a solid structure. This process creates a porous material that can trap

contaminants and other impurities, making it an effective filter for various applications.

1.High Porosity

One of the key advantages of sintered powder metal filters is their high porosity. The pores in the filter

are very small, typically ranging in size from 0.2 to 10 microns, which allows them to effectively remove

a wide range of contaminants from liquids and gases. It makes them ideal for use in the automotive,

aerospace, and medical industries, where cleanliness and purity are essential.

2.Durability

Another advantage of sintered powder metal filters is their durability. The sintering process creates a

strong, solid structure resistant to wear and tear, allowing the filter to withstand high pressures and

temperatures without deforming or breaking. It makes them suitable for use in demanding environments,

such as in engines or other high-performance machinery.

3. Easy Clean

One of the challenges of using sintered powder metal filters is that they can be difficult to clean and reuse.

Because the pores are so small, removing trapped contaminants from the filter can be difficult, making it

necessary to replace the filter rather than clean it. It can be costly, especially for applications where the

filter is used frequently. sure also have some method to clean.

Despite this limitation, sintered powder metal filters are widely used due to their effectiveness and durability.

They are an essential component in many industrial and manufacturing processes, which help ensure the

purity and quality of liquids and gases. With their ability to trap a wide range of contaminants and withstand

demanding environments, sintered powder metal filters are an important tool for maintaining the performance

and reliability of machinery and equipment.

Why HENGKO Sintered Powder Metal Filters

Supply Outstanding Filtration Solutions

Our kinds of sintered powder metal filter solutions are outstanding in a wide variety of demanding applications;

porous sinter metal's unique properties are used in various high-pressure sparging equipment for a fine and

uniform distribution of gases into liquids.

Porous sintered powder metal filters, often with flow-optimized large area connectors, are used to separate

solids from gas streams in various processes. The Main features are as follows:

1. High-temperature resistance, Thermal stability up to 950°C

2. Suitable for high differential pressure

3. High corrosion resistance

4. Unique sinter bonded connector

5. Self-supporting structure with high mechanical strength

6. Excellent back pulse performance

7. No welding of porous media

8. Design flexibility, Various shapes available, and customize

9. Over 10,000 variety of standard and custom sizes/shapes are available

10. Main For homogeneous gas/liquid distribution

11. Adopt Food-class 316L and 304L stainless steel or bronze

12. Easy Cleanable and Reusable Materials

OUR Technical

As a top-quality manufacturer of innovative porous metal filter products, HENGKO offers state-of-the-art technology solutions

for high-temperature and corrosive environments.

Normally sintered powder metal filter elements are made of stainless steel, bronze, nickel-based alloys, and titanium and can

be seamlessly welded with some special alloys to customize to a different shape with a threaded connector or air nozzle.

Defined filtration by exact pore size distribution.

Materials Option

HENGKO is available in a range of materials.

The powder metal solution makes tailoring design and requirements to individual process requirements easy.

Available materials:

1. Stainless Steel (standard 316L),

2. Hastelloy,

3. Inconel,

4. Monel,

5. Bronze,

6. Titanium

7. Special Alloys on request.

Applications

1. Gas Filtration

We supply multiple products and solutions for filtration of hot gases in industrial applications, and the operating temperatures

usually exceed 750°C for a long time. These filters most often function in systems equipped with automatic self-cleaning

capabilities, and the filter elements must be capable of full regeneration on each cycle. so the sintered powder metal filters

are the best choice, and all features can meet; that way, our porous melt filters are used increasingly in many gas

filtering industries.

2. Sparging

Much high-pressure equipment needs filter elements, such as gas-liquid contacting required for a reaction: stripping, mixing,

or diffusion. In many other applications, we help you maximize process efficiency by recommending and designing the best

suitable solution based on a large variety of available sparger units.

3. Liquid Filtration

We also offer custom-designed and self-supporting melt filter elements down to a filter efficiency of 0.1µm in liquid. The

sintered powder metal filters can be designed with a dual sandwich, and two sinter-connected powder grades offer

Consistent and homogeneous release and improve flow compared to conventionally designed filters. The sintered

porous disc is the perfect filter for processes involving a catalyst. Our sintered powder metal filter elements have a

lifetime that exceeds most competing solutions because of the no welding design with a "solid-solid" connection.

4. Fluidizing

We offer to customize fluidizing equipment for new and existing industrial systems by tediously controlling different

designs of filter manufacturing to ensure optimal gas distribution that results in perfect mass flow or mixing for many

different media, including bronze, stainless steel, and polyethylene. In addition, because fluidizing cones made of

stable sintered metal materials are usually self-supporting, we can usually supply filters with connecting flanges

as required.

OUR Partner

Till Now HENGKO have work thousand of companies from many industry included chemestry and oil, food, medical etc

Also many laboray of companies and university for long-term partner supplier. Hope you will be one of them,

contact us today if interested.

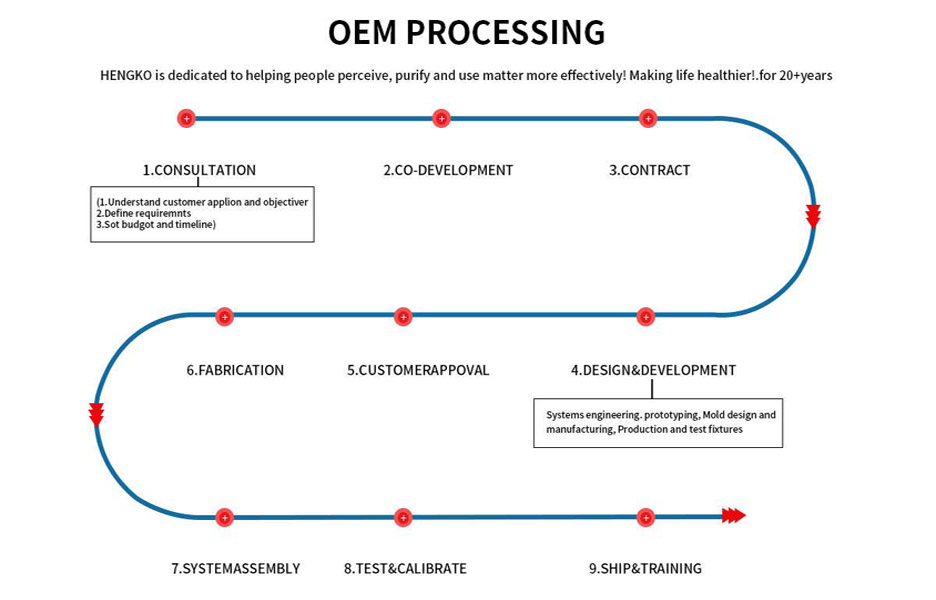

How to Customize Sintered Powder Metal Filters From HENGKO

When You have some Special Design Sintered Melt Filter for your projects and can not find the same or similar Filter

products, Welcome to contact HENGKO to work together to find the best solution, and here is the process of

OEM Porous Melt Filter Please Check it and Contact us talk more details.

HENGKO is Dedicated to Helping People Perceive, Purify and Use Matter More Effective ! Making Life Healthier Over 20 Years.

1. Consultation and Contact HENGKO

2. Co-Development

3. Make a Contract

4. Design & Development

5. Customer approved

6. Fabrication /Mass Production

7. System Assembly

8. Test & Calibrate

9. Shipping

So what is your industry ? and do you have any questions about the metal filters and need us to deal with or customize

special porous metal filters for your device and machine? Please just feel free to send us inquiry, Our R&D team will

be able to provide you with fast and satisfactory answers.

FAQ

1. What is sintering in powder metallurgy ?

Sintering is used in powder metallurgy to convert metal powders into a solid, porous material. This process involves

heating the metal powders to a temperature just below their melting point, which causes the particles to bond

together and form a solid structure.

The sintering process is commonly used in manufacturing metal parts and components, such as bearings, gears,

and filters. It offers several advantages over other manufacturing methods, such as casting or forging, including

lower costs, greater design flexibility, and the ability to create complex shapes and structures.

During the sintering process, the metal powders are placed in a mold or die, which determines the shape of the

finished part. The mold is then placed in a furnace, where it is heated to a temperature just below the melting

point of the metal. As the metal powders are heated, they begin to bond together and form a solid structure.

As the metal powders sinter, the pores between the particles become smaller and smaller. It creates a porous

material that is strong and durable but also has a high surface area, which makes it ideal for applications such

as filtration and catalyst support. It can control the size and distribution of the pores by adjusting the sintering

temperature and time and the composition of the metal powders.

Once the sintering process is complete, the solid, porous material is removed from the mold and allowed to

cool. The finished part can then be machined or processed to create the desired shape and size.

Sintering is a versatile process that can create many metal parts and components. It offers many advantages,

including low costs, design flexibility, and the ability to create complex shapes and structures. As a result,

sintering is widely used in manufacturing metal parts and components in the automotive, aerospace, and

medical industries.

2. Why is sintering important in powder metallurgy?

Sintering is an important process in powder metallurgy because it bonds the particles in a metal powder to

form a solid, cohesive material. It is done by heating the powder to a temperature below its melting point,

which causes the particles to bond through diffusion.

Sintering is important for several reasons:

1. It allows for creating parts with complex shapes that would be difficult or impossible to produce

using other manufacturing techniques.

2. It can use to produce parts with improved mechanical properties, such as greater strength

and hardness.

3. Sintering can create porous materials with a controlled porosity, which is useful for applications

such as filters and catalysts.

The sintering process typically involves heating the powder to a temperature of around 80-90%

of its melting point under conditions of high pressure and a controlled atmosphere. It causes the

particles to diffuse into each other, forming a solid mass. The sintering process can be controlled

to produce a wide range of microstructures and mechanical properties, depending on the specific application.

One of the key advantages of powder metallurgy is that it allows for the creation of parts with complex shapes

and precise tolerances. It is because the metal powder can be formed into any shape using various techniques,

such as pressing and sintering. This flexibility allows manufacturers to produce parts with complex geometry

and precise dimensions, which is impossible with other manufacturing techniques.

In conclusion, sintering is an important process in powder metallurgy because it allows for creation of parts

with complex shapes, improved mechanical properties, and controlled porosity. It is a key step in the powder

metallurgy process and enables manufacturers to produce high-quality parts for various applications.

So if still have Any Questions and Interested for the Sintered Powder Metal Filters, You are welcome to

contact us by email ka@hengko.com and also you can send inquiry by follow inquiry form, we will send

back within 24-Hours.