-

Waterproof stainless steel porous anti-explosion co2 ethylene nitrogen oxygen gas senso...

HENGKO explosion proof sensor housing are made of 316L stainless steel and aluminium for maximum corrosion protection. A sinter bonded flame arrestor provide...

View Detail -

Nitro Cold Brew Nitrogen 0.5 Micron and 2 Micron Diffusion Stone Works with Infusion Ke...

Looking for a better way of infusion your cold brew coffee with nitrogen? You found it! One of the nitrogen-infused coffee hallmarks is that sweet cascade ...

View Detail -

Nitrogenous wine Tool Diffusion Professional Effective Aeration Stone Beer Brewage 316L...

Product Name Specification SFB01 D1/2''*H1-7/8'' 0.5um with 1/4'' Barb SFB02 D1/2''*H1-7/8'' 2um with 1/4'' Barb SFB03 D1/2''*H1-7/8'' 0.5um...

View Detail -

Stainless steel 316 micro sintered nitrogen diffusion stone with barb connector Used in...

Coffee, like all other food & beverage products, must go through a preservation process to keep the beans fresh during storage and packaging before the...

View Detail -

Custom stainless steel 316L nitrogen gas filter tube for multipurpose filtration

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Professional Manufacturer Customized nano capillary nitrogen tube for lead-life reflow ...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Custom stainless steel 316L nitrogen sintered filter cartridge for Lead-free reflow ove...

HENGKO offers nitrogen gas soldering application solutions for reflow and wave soldering, solving the major problems faced by the electronics assembly and ...

View Detail

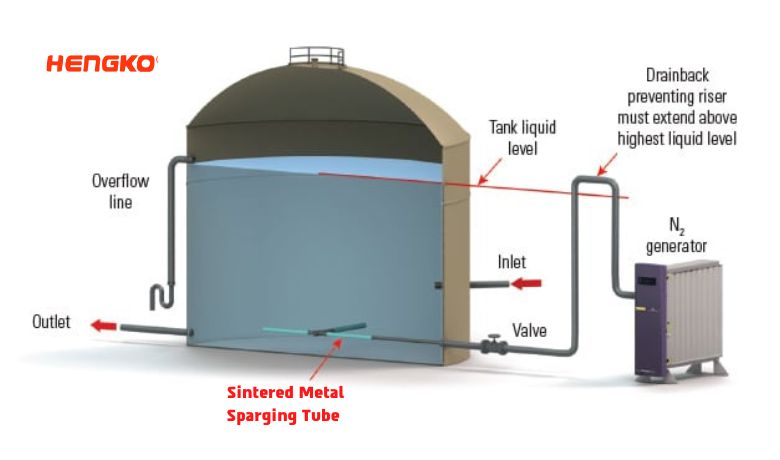

Main feature of Nitrogen Sparger

A Nitrogen Sparger is a device used to introduce nitrogen gas into a liquid. The main feature of a Nitrogen Sparger is that it allows for the efficient introduction of a large volume of nitrogen gas into a liquid, typically to achieve a desired level of dissolved nitrogen in the liquid. There are various purposes, such as providing an oxygen source for aerobic bacteria in a bioreactor or creating a blanket of nitrogen gas to prevent oxidation in a chemical reactor.

1. Efficient introduction of a large volume of nitrogen gas into a liquid

2. Allows for precise control of the amount of dissolved nitrogen in the liquid

3. Various purposes, such as providing oxygen for aerobic bacteria or creating a blanket of nitrogen gas to prevent oxidation.

4. Various applications, including bioreactors and chemical reactors.

5. It can be designed with different types of sparging systems, such as a porous tube, a hollow fiber membrane, or a disk diffuser, depending on the specific application's requirements.

6. It can be automated to control the flow of nitrogen and dissolved nitrogen levels.

7. Prevent oxidation and contamination in the liquid.

How does Nitrogen Sparging Work ?

Nitrogen sparging is a process in which nitrogen gas is bubbled through a liquid to remove other dissolved gases or volatile components from that liquid. It is a mass transfer operation that relies on the principle of Henry's law, which states that the concentration of a gas in a liquid is proportional to the partial pressure of that gas in the gas phase above the liquid.

Nitrogen is an inert gas, meaning that it does not react with most other chemicals. This makes it ideal for sparging applications, as it can be used to remove oxygen and other unwanted gases from liquids without introducing any new impurities.

Nitrogen sparging is typically carried out by bubbling nitrogen gas through a liquid using a diffuser. The diffuser is a device that breaks up the nitrogen gas into small bubbles, which increases the surface area of the gas-liquid interface. This allows for more efficient mass transfer of the unwanted gases from the liquid to the gas phase.

The flow rate of the nitrogen gas is typically adjusted to ensure that the liquid is thoroughly sparged. The sparging time will vary depending on the application, but it is typically continued until the desired level of purity is achieved.

Nitrogen sparging is used in a wide variety of industries, including:

* Food and beverage: Nitrogen sparging is used to remove oxygen from food and beverage products to extend their shelf life and prevent spoilage.

* Water treatment: Nitrogen sparging is used to remove volatile organic compounds (VOCs) and other contaminants from wastewater.

* Chemical industry: Nitrogen sparging is used to remove oxygen and other unwanted gases from chemical products to prevent unwanted reactions and ensure product quality.

* Pharmaceutical industry: Nitrogen sparging is used to remove oxygen and other impurities from pharmaceutical products to ensure their safety and efficacy.

Here are some specific examples of how nitrogen sparging is used in different industries:

* Beer brewing: Nitrogen sparging is used to remove oxygen from beer before it is packaged. This helps to prevent spoilage and off-flavors.

* Wastewater treatment: Nitrogen sparging is used to remove VOCs from wastewater before it is discharged into the environment.

* Semiconductor manufacturing: Nitrogen sparging is used to remove oxygen and other impurities from water used in the semiconductor manufacturing process. This helps to prevent defects in the semiconductor products.

* Pharmaceutical manufacturing: Nitrogen sparging is used to remove oxygen and other impurities from pharmaceutical products before they are packaged. This helps to ensure the safety and efficacy of the products.

Nitrogen sparging is a versatile and effective process for removing unwanted gases and volatile components from liquids. It is used in a wide variety of industries to improve the quality and safety of products, extend shelf life, and protect the environment.

How to OEM Nitrogen Sparger, What You Should Care ?

When OEM (original equipment manufacturer) produces Nitrogen Spargers, some important factors you should consider include the following:

1. Materials: The materials used to construct the sparger should be suitable for the specific application and withstand the chemical and physical properties of the liquid or gas injected.

2. Design: The sparger design should be optimized for efficient and effective nitrogen injection. The Main includes the size, shape, and number of injection points.

3. Quality control: The manufacturing process should include strict measures to ensure the spargers are free from defects and meet the required specifications.

4. Compatibility: The sparger should be compatible with the equipment it will use and have the necessary connections and fittings.

5. Certification: The sparger should comply with relevant industry standards and regulations and have the necessary certifications.

6. Customization: The sparger should be customizable to meet the specific needs and requirements of the customer.

7. Cost-effective: The sparger should be cost-effective in terms of manufacturing and maintenance costs.

8. After-sales service: The OEM should provide good after-sales service to ensure the sparger is installed and maintained correctly and to provide customer support as needed.

Application of Nitrogen Sparger

1. Aeration: Nitrogen spargers are used in wastewater treatment to provide aeration and oxygenation of the water. It helps to break down organic matter and promote the growth of beneficial bacteria.

2. Carbonation: Nitrogen spargers are used in the beverage industry to inject nitrogen into carbonated drinks to create a creamy texture and a consistent head of foam.

3. Inert : Nitrogen spargers can create an inert atmosphere in tanks or vessels, which is useful for storing or transporting flammable or explosive materials.

4. Mixing: Nitrogen spargers can mix liquids, gases, or powders in industrial processes, such as food processing, pharmaceutical manufacturing, and chemical production.

5. Leaching: Nitrogen spargers can dissolve and extract valuable minerals or metals from ores by injecting nitrogen into the leaching solution.

6. Cooling: Nitrogen spargers can cool down hot materials, such as molten metal, by injecting a nitrogen gas stream, which helps to cool down the material quickly and efficiently.

FAQ about nitrogen sparging and nitrogen sparger

1. What is Nitrogen Sparging?

In short, Nitrogen sparging is a process in which nitrogen gas is injected into a liquid, typically water or a liquid solution, to create a specific effect. It can include aerating the liquid to promote the growth of beneficial bacteria, creating an inert atmosphere, or dissolving and extracting valuable minerals or metals.

The main purpose of nitrogen sparging is to displace or remove oxygen and other gases that can negatively affect the quality, stability, or reactivity of the liquid being treated. By introducing nitrogen gas into the liquid, the oxygen is displaced, and the concentration of dissolved gases is reduced. Nitrogen is often preferred for this purpose because it is an inert gas that does not react with most substances.

Nitrogen sparging is typically carried out by passing a stream of nitrogen gas through a distribution system, such as a sparging stone or a diffuser, which is submerged in the liquid. The gas bubbles rise through the liquid, creating agitation and promoting the release of dissolved gases into the atmosphere.

The benefits of nitrogen sparging include:

1. Oxygen removal:

Nitrogen sparging helps eliminate oxygen from the liquid, which is important in preventing oxidation reactions that can degrade sensitive substances or promote microbial growth.

2. Inert atmosphere:

The use of nitrogen gas creates an inert environment, which is desirable in processes where the presence of reactive gases can cause undesired reactions or degradation.

3. Improved product quality:

By reducing the concentration of dissolved gases, nitrogen sparging can enhance the stability, shelf life, and overall quality of the liquid product.

4. Safety:

Nitrogen sparging can be used to create a non-flammable or less flammable atmosphere, reducing the risk of fire or explosion in certain applications.

Overall, nitrogen sparging is a valuable technique used to control the gas composition in liquids, promote chemical reactions, protect sensitive substances, and improve product quality in various industrial processes.

2. What are the benefits of nitrogen sparging?

The benefits of nitrogen sparging can include improved efficiency in wastewater treatment, enhanced product quality in the beverage industry, and increased safety when working with flammable or explosive materials. It can also cool down hot materials, mix, and leach.

3. How does a nitrogen sparger work?

A nitrogen sparger works by injecting nitrogen gas into a liquid through a series of small openings or injection points. The nitrogen bubbles create a rise to the surface and transfer their buoyancy energy to the liquid, promoting mixing and the desired effect, such as oxygenation or inert.

4. What types of liquids can be treated with nitrogen sparging?

Nitrogen sparging can be used on various liquids, including water, wastewater, food and beverage production, and chemical solutions.

5. What are the different types of nitrogen spargers available?

Several nitrogen spargers are available, including ceramic, porous metal, and hollow-tube spargers. The type of sparger best suited for a specific application will depend on factors such as the chemical properties of the treated liquid and the required flow rate.

6. How do you maintain a nitrogen sparger?

Maintenance for a nitrogen sparger typically includes regular cleaning and inspection of the injection points to ensure they are free from clogs or blockages. It is also important to check the connections and fittings to ensure they are secure and not leaking. The OEM should be able to provide more detailed instructions on how to maintain the specific model of nitrogen sparger that you are using.

7. How do you choose the right nitrogen sparger for your application?

When choosing a nitrogen sparger, it is important to consider factors such as the chemical properties of the liquid being treated, the required flow rate, and the specific effects you are trying to achieve. Other factors that need to consider included the materials of construction, the size and number of injection points, and compatibility with your existing equipment.

8. Can nitrogen spargers be used in hazardous environments?

Some nitrogen spargers are specifically designed for use in hazardous environments, such as those that involve flammable or explosive materials. These spargers will typically be constructed from materials resistant to corrosion and fire and have safety features such as explosion-proof enclosures.

9. How much nitrogen is required for sparging?

The amount of nitrogen required for sparging will depend on factors such as the flow rate, the size of the sparger, and the desired effects. It is important to consult the manufacturer's specifications for the specific sparger you use to determine the appropriate nitrogen flow rate.

10. What are the potential drawbacks of nitrogen sparging?

Some potential drawbacks of nitrogen sparging include the cost of the nitrogen gas and equipment, the need for regular maintenance, and the potential for leaks or spills if the equipment is not properly maintained. Additionally, nitrogen sparging may not be suitable for all liquids or applications.

11. How nitrogen sparging to remove oxygen ?

Nitrogen sparging is an established technique employed in various industries to effectively remove oxygen from liquids. By introducing nitrogen gas into a liquid medium, the process displaces dissolved oxygen, thereby creating an oxygen-free environment. This controlled displacement is achieved due to the inert nature of nitrogen, which does not react with the liquid or its constituents.

1. The process of nitrogen sparging involves the introduction of a stream of nitrogen gas into the liquid through a distribution system, typically a sparging stone or a diffuser. These devices facilitate the dispersal of nitrogen gas in the form of small bubbles throughout the liquid medium, promoting efficient contact and mixing.

2. As the nitrogen bubbles ascend through the liquid, they come into contact with dissolved oxygen molecules. Due to the concentration gradient between the dissolved oxygen and the nitrogen gas, oxygen molecules diffuse from the liquid into the gas phase. This diffusion process continues until equilibrium is reached, resulting in a significant reduction of dissolved oxygen concentration within the liquid.

3. The agitation caused by the rising nitrogen bubbles further aids in the removal of oxygen. The agitation disrupts the boundary layer near the liquid's surface, which enhances the mass transfer of oxygen from the liquid phase to the gas phase. Consequently, the overall oxygen content in the liquid is substantially reduced.

4. By effectively removing oxygen, nitrogen sparging serves several critical purposes. First and foremost, it prevents undesirable oxidative reactions that can degrade sensitive substances or alter the chemical composition of the liquid. Oxygen, known for its reactivity, can lead to the degradation of organic compounds, oxidation of sensitive pharmaceuticals, or spoilage of food and beverages. Thus, nitrogen sparging ensures product integrity and stability.

Furthermore, nitrogen sparging creates an inert atmosphere within the liquid. This inert environment is beneficial in processes where reactive gases, including oxygen, can lead to unwanted reactions or promote the breakdown of valuable compounds. By eliminating the presence of oxygen, nitrogen sparging provides a controlled and non-reactive environment that preserves the integrity of the liquid and its constituents.

In summary, nitrogen sparging is a highly effective method for removing oxygen from liquids. Through the introduction of nitrogen gas and the subsequent displacement of dissolved oxygen, this process mitigates the risks of oxidation, enhances product quality, and facilitates controlled reactions in numerous industries, including pharmaceuticals, chemicals, and food and beverage production.

How Long do i Sparge with Nitrogen to Deaerate ?

The amount of time required to deaerate a liquid using nitrogen sparging depends on a number of factors, including:

1. Volume of Liquid:

Larger volumes of liquid generally require longer sparging times.

2. Concentration of Dissolved Gases:

If the liquid has a high concentration of dissolved gases, it will take longer to deaerate.

3. Sparging Technique:

Different sparging devices and techniques can affect the efficiency of gas removal. Fine bubble

sparging, for instance, is often more efficient than coarse bubble sparging.

4. Desired Level of Deaeration:

The required purity level of the deaerated liquid will influence the sparging time.

Complete deaeration might take longer than partial deaeration.

5. Temperature and Pressure:

The solubility of gases in liquids decreases with increasing temperature and decreasing pressure.

Adjusting these parameters can influence the efficiency and speed of deaeration.

A general rule of thumb is to sparge the liquid for a minimum of 1 hour per liter of liquid.

However, for more demanding applications, such as the deoxygenation of pharmaceutical products,

it may be necessary to sparge the liquid for several hours or even days.

One way to determine when the liquid has been sufficiently deaerated is to measure the dissolved oxygen concentration in the liquid using an oxygen meter. Once the desired level of deaeration has been achieved, the sparging process can be stopped.

Here are some additional tips for improving the efficiency of nitrogen sparging:

* Use a diffuser that creates small bubbles.

This will increase the surface area of the gas-liquid interface and improve mass transfer.

* Sparge the liquid at a temperature that is above the boiling point of water. This will help to remove oxygen and other dissolved gases more quickly.

* Use a vessel that has a large surface area to volume ratio. This will also improve mass transfer.

* Agitate the liquid during sparging.

This will help to break up the bubbles and increase the surface area of the gas-liquid interface.

If you are unsure of the optimal sparging time for your particular application, it is best to consult with a qualified engineer or chemist.

Here you can check the Nitrogen Sparger Video by the Nitrogen Sparger Tube

Then, if have any questions or interested for the Nitrogen Sparger, you are welcome to send email by

ka@hengko.com to contact us.

Also you can easy to fill the form to send us a inquiry for our Nitrogen Sparger products. we will send

back and send the solution within 24-hours.