-

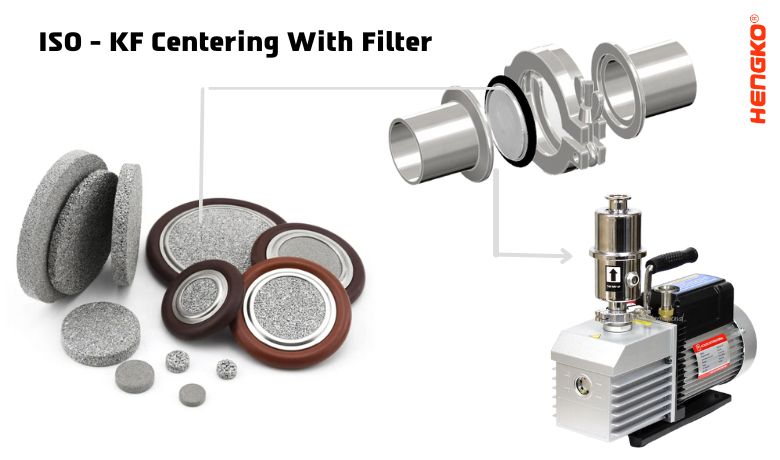

NW16 KF16 Flange-Centering O-Ring with Fine Filter

ISO-KF and NW Sintered Metal Filter Centering Ring NW-16、NW-25、NW-40、NW-50 Supplier With fine filter (sintered porous metal filter or choose wire mesh f...

View Detail -

NW50 KF50 Vacuum Flange Centering ring with Sintered Metal Filter, stainless steel, 50 ...

NW50 KF50 Centering ring with Sintered Metal Filter, stainless steel, 50 ISO-KF Product material: stainless steel 304,316 Installation method: use with clam...

View Detail -

NW25 KF25 KF Centering Ring to Sintered Metal Filter

NW25 KF25 KF Centering Ring to Sintered Metal Filter • NW16 (KF16, QF16) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Pore Size• F...

View Detail -

vacuum KF certering ring with Sintered Metal Filter

Product Describe The Flange Connections Centering rings with Sintered Metal Filter in vacuum technology are used up to the high vacuum range of 10 to -7 mbar...

View Detail -

sintered metal stainless steel filters with centering ring used to build foreline vacuu...

Code Flange HKF10 NW10KF HKF16 NW16KF HKF20 NW20KF HKF25 NW25KF HKF40 NW40KF HKF50 NW50KF HENGKO centering ring assemblies with sintered ...

View Detail

Main Features and Applications

Suction filters for vacuum pumps and compressors

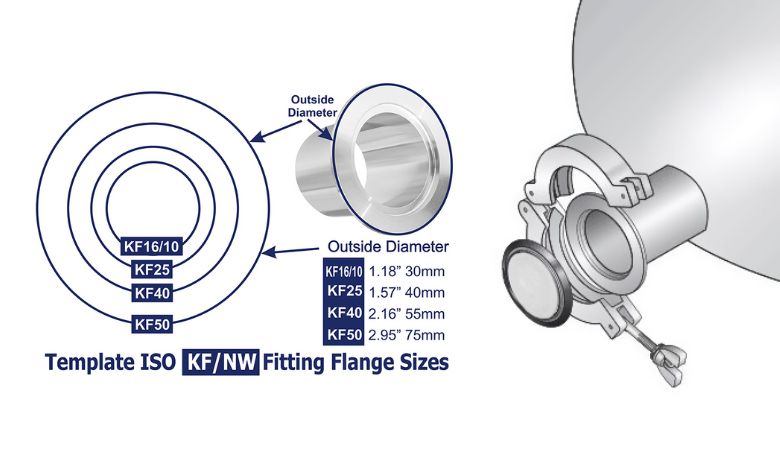

Purchase or Custom your Centering ring KF10, KF16, KF25, KF40 even - KF160 SS 316L, FKM O'ring, with mesh screen or Sintered metal filter for your vacuum pump on HENGKO. Can match over 20 brands of vacuum pumps or compressors, real factory price, 50% cheaper than market.

Some Application of the Centering Ring Filters

1. Eco Filters:

Cost-effective filters compatible with all models of vacuum pumps from various manufacturers. The interchangeable elements include:

1. Paper (6μm).

2. Washable polyester (10μm).

3. Washable pleated stainless steel cloth (60μm).

4. Activated carbon (for trapping condensable vapors).

The filters are constructed with carbon steel and coated with epoxy paint.

They feature a female threaded connection to the gas pitch and closure by hooks.

5. Air Inlet Filters: Affordable filters for air inlets of compressors. Interchangeable elements include paper (6μm),

washable polyester (10μm), and washable pleated stainless steel fabric (60μm). The filters are constructed with

carbon steel and coated with epoxy paint. They connect via a collar or threaded tube with a gas pitch.

2. Oil Bath Filters:

Designed to be mounted on the suction side of vacuum pumps or compressors, these filters protect the equipment from large amounts of dust. Removable, washable, and available sizes from 1/2 "G to 2" G. The filters are constructed with carbon steel and coated with epoxy paint. They feature a female threaded connection to the gas pitch.

Visi-trap:

Suction filters for vacuum pumps with a transparent plastic body (SAN). Filter elements come in two sizes: 4.5" and 9.5" NPT female or KF25 and KF40. There are 8 options for filter elements: copper straw (for condensable particles and vapors), stainless steel straw (for condensable particles and vapors with better corrosion resistance), molecular sieve (for eliminating backscattering from mechanical pumps and protecting the pump from steam water), sodium lime (for fixing corrosive or acidic products), activated carbon (for fixing organic vapors), polypropylene 2μm, 5μm, and 20μm (for particles and are washable).

Posi-trap:

Suction filters for stainless steel vacuum pumps are available in two sizes: DN100 (1 filter element) and DN200 (4 filter elements). The connection can be a line or 90° and is available in KF25, KF40, and KF50. The filter elements come in 8 options: copper straw (for condensable particles and vapors), stainless steel straw (for condensable particles and vapors with better corrosion resistance), molecular sieve (for eliminating backscattering from mechanical pumps and protecting the pump from steam water), sodium lime (for fixing corrosive or acidic products), activated carbon (for fixing organic vapors), polypropylene 2μm, 5μm, and 20μm (for particles and are washable).

Multi-trap:

Suction filters for high-performance vacuum pumps for demanding applications (LPCVD, PECVD, ALD, MOCVD, Metal Etch, HVPE, extrusion, etc.) that generate large amounts of particles and condensable vapors. These filters come in three sizes, all with stainless steel construction, and offer multiple options, including multi-stage and cooling coil. The filter elements come in 8 options: copper straw (for condensable particles and vapors), stainless steel straw (for condensable particles and vapors with better corrosion resistance), molecular sieve (for eliminating backscattering from mechanical pumps and protecting the pump from steam water), sodium lime (for fixing corrosive or acidic products), activated carbon (for fixing organic vapors), polypropylene 2μm, 5μm, and 20μm (for particles and are washable). The filter elements can be used alone or combined for multi-stage models.

Application

The KF (Klein Flange) centering ring with filter is an integral component in vacuum applications, serving a critical role in sealing and filtration. The KF centering ring aligns and seals vacuum flanges, and the filter part keeps contaminants from entering the system. Here are some applications:

1.Semiconductor Manufacturing:

2. Mass Spectrometry:

3. Pharmaceutical Manufacturing:

4. Material Science and Research:

5. Space Simulation Chambers:

In all of these applications, the KF centering ring with filter ensures a reliable seal and prevents the introduction of contaminants into the vacuum system. It's a small component with a significant impact on the reliability and accuracy of many vacuum-dependent processes and experiments.

Interested in enhancing your vacuum systems with our superior-quality OEM KF Centering Rings with Filters?

We'd love to hear from you! No matter what your application, our team of experts is on hand to provide detailed information and tailored solutions to meet your unique needs.

Take your operations to the next level with our high-performance components, designed for reliability and precision. Don't compromise on quality – choose our KF Centering Rings with Filters for optimum results in your vacuum applications.

To find out more and discuss your specific requirements, reach out to us today at ka@hengko.com. We're looking forward to partnering with you to achieve the best in your business!

All You Should Know About

KF Centering Ring With Filter for Vacuum Pump

KF Centering Ring With Filter is a component used in vacuum pump systems to protect the pump from debris

and particulate matter. It is a crucial component that ensures the smooth operation and longevity of the vacuum pump.

Reasons for using a KF Centering Ring With Filter

1. Prevents damage to the vacuum pump:

Debris and particulate matter can damage the internal components of the vacuum pump, leading to

reduced performance, increased wear and tear, and potential breakdowns. A KF Centering Ring With

Filter effectively traps these contaminants, preventing them from entering the pump and causing damage.

2. Extends the lifespan of the vacuum pump:

By preventing damage from debris and particulate matter, a KF Centering Ring With Filter contributes

to the overall longevity of the vacuum pump, reducing maintenance costs and the need for frequent replacements.

3. Maintains optimal vacuum performance:

Debris and particulate matter can interfere with the efficient operation of the vacuum pump, reducing its

suction capacity and creating fluctuations in vacuum pressure. A KF Centering Ring With Filter helps maintain

consistent and optimal vacuum performance.

Features of a KF Centering Ring With Filter

1. Stainless steel construction:

KF Centering Rings With Filter are typically made from durable stainless steel,

ensuring resistance to corrosion and wear and tear, even in harsh industrial environments.

2. Sintered metal filter:

The filter element is typically made from sintered metal, a specialized material with a

porous structure that effectively traps debris particles of various sizes.

3. O-ring seal:

An O-ring seal provides a tight and leak-proof connection between the KF Centering Ring With

Filter and the vacuum pump flange, preventing air leaks that could affect vacuum performance.

4. Various sizes and configurations:

KF Centering Rings With Filter are available in various sizes and

configurations to match different vacuum pump models and flange sizes.

Function of a KF Centering Ring With Filter

1. Alignment:

The KF Centering Ring With Filter aligns the vacuum pump flange with the connecting flange,

ensuring a proper fit and preventing misalignment that could cause leaks or damage.

2. Filtration:

The sintered metal filter traps debris and particulate matter as the air or gas passes through the

KF Centering Ring With Filter, protecting the vacuum pump from contamination.

3. Sealing:

The O-ring seal prevents air leaks between the KF Centering Ring With Filter and the flanges,

maintaining the vacuum pressure within the system.

Choosing the Right KF Centering Ring With Filter

1. Consider the vacuum pump model:

Ensure that the KF Centering Ring With Filter is compatible with the specific model and size of your vacuum pump.

2. Match the flange size:

The KF Centering Ring With Filter should match the diameter of the vacuum pump flange and the connecting flange to ensure a proper fit.

3. Select the appropriate filter porosity:

Choose a filter porosity that is suitable for the type of debris and particulate matter you expect to encounter. Finer porosity filters will trap smaller particles but may restrict airflow slightly.

4. Choose a durable material:

Opt for a KF Centering Ring With Filter made from high-quality stainless steel to ensure resistance to corrosion and wear and tear.

How Replacing a KF Centering Ring With Filter

1. Disassemble the vacuum pump connection:

Disconnect the vacuum pump from the connecting flange.

2. Remove the old KF Centering Ring With Filter:

Carefully remove the old centering ring and filter element.

3. Inspect the flanges and O-ring:

Clean and inspect the vacuum pump flange and connecting flange for any damage or debris. Replace the O-ring if it is damaged or worn.

4. Install the new KF Centering Ring With Filter:

Place the new centering ring and filter element onto the vacuum pump flange.

5. Reassemble the vacuum pump connection:

Carefully reattach the connecting flange to the vacuum pump.

6. Leak test the connection:

Check for any air leaks around the connection using an appropriate leak detection method.

By following these steps and selecting the appropriate KF Centering Ring With Filter,

you can effectively protect your vacuum pump from debris and particulate matter, ensuring its

optimal performance and longevity.

FAQ about KF Center Ring

1. What is a KF Center Ring with Mesh Filter/Sintered Metal Filter?

A KF (Klein Flange) centering ring with a mesh filter or sintered metal filter is a critical component used in vacuum systems, which includes two main parts: the centering ring and the filter.

-

Centering Ring: This part helps align and seal two flanges of a vacuum system, ensuring a leak-tight seal. It is generally made of a rubber-like elastomer (often Viton or Buna-N), which can adapt to the irregularities of the flange surfaces to prevent any leakage of air into the vacuum system.

-

Mesh Filter/Sintered Metal Filter: This part is incorporated within the centering ring. Its purpose is to filter out dust, particles, or other contaminants that might compromise the quality of the vacuum or the process being conducted within it. The filter can be a simple mesh (which traps larger particles) or a sintered metal filter. Sintered metal filters are made from small metal particles that are heated until they bond together, creating a porous but strong filter that can trap very fine particles.

The KF centering ring with a mesh or sintered metal filter thus serves a dual purpose in a vacuum system: sealing the system to maintain the vacuum, and filtering the system to prevent contamination. This makes them essential for applications that require clean, consistent vacuum conditions, such as semiconductor manufacturing, chemical processing, food processing, pharmaceuticals, and scientific research.

2. How does a mesh filter differ from a sintered metal filter in a KF Center Ring?

A mesh filter is a stainless wire that captures large particles and impurities. A sintered metal filter is made of metal powder that has been compressed and sintered to form a porous structure. It is designed to remove finer particles and impurities.

3. What are the benefits of using a mesh or a sintered metal filter in a KF Center Ring?

The incorporation of a mesh or a sintered metal filter in a KF Centering Ring offers several benefits, particularly in applications requiring high levels of cleanliness and particle control within vacuum systems. Here are some key benefits:

-

Improved Particle Filtration: Both mesh and sintered metal filters can trap dust, particles, and other potential contaminants, thus preventing them from entering the vacuum system. This is essential for maintaining the integrity and cleanliness of processes conducted within the system.

-

High Temperature Resistance: Sintered metal filters, in particular, can withstand high temperatures without losing their structural integrity or filtration capabilities. This makes them suitable for applications involving high temperatures.

-

Chemical Resistance: Both mesh and sintered metal filters are typically made of materials that are resistant to a wide range of chemicals. This makes them ideal for use in chemical processing applications or in environments where they may be exposed to various chemicals.

-

Enhanced Durability: Sintered metal filters are known for their high durability due to the sintering process, which bonds metal particles together to form a robust, yet porous structure. This allows for a long lifespan even in challenging operating conditions.

-

Customizable Pore Sizes: Sintered metal filters offer the advantage of customizable pore sizes, allowing for control over the level of filtration. This means they can be tailored to applications requiring specific particle size exclusion.

-

Easy Maintenance: Mesh and sintered metal filters are typically easy to clean or replace, making maintenance of the vacuum system more manageable.

-

Preservation of Vacuum Integrity: Perhaps most importantly, the use of a centering ring with an integrated filter helps maintain the seal on the vacuum system, preserving the vacuum integrity while also providing the filtration function. This dual functionality can help improve system performance and reliability.

By providing both filtration and sealing capabilities, a KF Centering Ring with a mesh or sintered metal filter can enhance the performance and reliability of a vacuum system, making it a valuable component in a range of industries and applications.

4. How do I choose a mesh or a sintered metal filter for my KF Center Ring?

The choice between a mesh filter or a sintered metal filter will depend on the specific requirements of your vacuum system, including the size and type of particles that need to be removed.

5. Can a mesh or sintered metal filter be reused in a KF Center Ring?

Yes, in most cases, a mesh filter or a sintered metal filter can be reused, but it will depend on the specific conditions of the vacuum system and the extent of the contamination.

6. How often should I replace the mesh or sintered metal filter in my KF Center Ring?

The replacement frequency will depend on the conditions of the vacuum system, including the level of contamination and the size of the particles being filtered. It is recommended to check the filter's condition periodically and replace it as needed.

7. What is the maximum temperature limit for a mesh or sintered metal filter in a KF Center Ring?

The maximum temperature limit will vary depending on the specific mesh or sintered metal filter used in the KF Center Ring. It is important to consult the manufacturer's specifications for the specific filter. For a Sintered metal filter with a center ring, the Max temperature can reach 600 degrees.

8. Can a mesh or sintered metal filter be cleaned and reused in a KF Center Ring?

Yes, in most cases, a mesh filter or sintered metal filter can be cleaned and reused, but it will depend on the vacuum system's specific conditions and the contamination's extent.

9. What are the maintenance requirements for a KF Center Ring with a mesh or sintered metal filter?

Maintenance requirements will depend on the specific mesh or sintered metal filter used in the KF Center Ring. It is recommended to consult the manufacturer's specifications for the specific filter used.

10. Are there special precautions to take when installing a mesh filter or sintered metal filter in a KF Center Ring?

Following the manufacturer's instructions when installing a mesh filter or sintered metal filter in a KF Center Ring is important. It will ensure proper installation and prevent filter or vacuum system damage.

Ready to take the next step towards finding the right solution for your needs? Look no further! At HENGKO, our team of experts is dedicated to helping you find exactly what you're looking for. Simply send us an email with Your Requires for the center ring at ka@hengko.com and we'll be in touch to discuss your specific requirements and how we can help. Don't miss out on this opportunity to work with the best in the business, send your inquiry today!