-

Stainless Steel 316 Micro Spargers and Filter in Bioreactors and Fermentors

Product Describe The function of the bioreactor is to provide a suitable environment in which an organism can efficiently produce a target product. * Cell b...

View Detail -

In-tank porous metal spargers or multiple sparger assembly for a large tank, increase g...

Attaches to the tip of the sparger tube, this 316L stainless steel sintered tip is available in a variety of pore sizes. The 5 10 15 50 100 pore frit is the ...

View Detail -

multi – bioreactor sparger for the fermenter sartorius

The Stainless Steel Fermenter|Bioreactor for Your Laboratory A bioreactor is a type of fermentation vessel that is used for the production of various chemica...

View Detail -

HENGKO OEM Sintered Steel Filter and Sparger

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. The...

View Detail -

Sintered Microsparger in Bioreactor System for Green chemistry industry

The importance of aeration and gas dispersion to achieve good oxygen mass transfer cannot be understated. This is at the heart of the ability of mic...

View Detail -

Replacement Micro-Bubble Porous Sparger Tips for Fermentation / Bioreactor Air Aeration...

Advantages of HENGKO Porous Metal Micro Spargers Due to the low solubility of oxygen in many cell culture mediums, optimizing this critical nutrient can be ...

View Detail -

Sintered Micro Porous Sparger in Benchtop for Bioreactors and Laboratory Fermenter

Every bioreactor sparging system is designed for the introduction of oxygen to feed cell cultures. Meanwhile, the system must remove carbon dioxide to preven...

View Detail -

Quick Change Sparger System for Bioreactors and Fermentors Air Sparger Accessories- Mic...

Stainless steel sparger is to supply enough oxygen to the microbes in submerge culture technique for proper metabolism. Each fermentation process requires a ...

View Detail -

316 L Powder Stainless Steel Metal Frit Spargers Building A Stainless Steel Filtering S...

Product Description This device is particularly good for fermentations that require a large population of yeast. Pilsners (or other beers fermented at low te...

View Detail -

HENGKO sintered porous carbonation stone air sparger bubble diffuser nano oxygen genera...

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Sintered Sparger Tube with Porous Metal Stainless Steel Tank and In-line Spargers Used ...

Introducing the exceptional HENGKO sintered spargers, the ultimate solution to introducing gases into liquids. This innovative product utilizes thousands of...

View Detail -

HENGKO micron small bubble air sparger oxygenation carbanation stone used in acrylic wa...

Product Describe HENGKO air sparger bubble stone is stainless steel 316/316L, food grade, with a beautiful appearance, suitable for hotels, fine dining and o...

View Detail -

Sintered Sparger Stainless Steel Material Quick Change for Bioreactor Systems

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Aeration Stone 20um Sintered Stainless Steel 316L Micro sparger Diffusion Stone Supplier

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Sintered 316l stainless steel bubble hydrogen-rich water generator air sparger

Product Description Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of di...

View Detail -

Stainless Steel Ozone Diffuser Stone Fine Air Sparger for Hydrogen Generator

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Stainless Steel Aeration/Oxygen CO2 Diffusion Stone Micro Sparger for Microalgae Cultiv...

Micro-diffuser for Microalgae Cultivation, Photobioreactors & sintered sparger for microalgae cultivation is used in laboratories for growing algae. HEN...

View Detail -

Biotech Removable Porous Frit Micro Sparger for Mini Bioreactor System and Fermentors

Stainless steel sparger used as a cell retention device. The device consists of a metal tube and a sintered metal filter with a pore size of 0.5 – 40 µm. The...

View Detail -

sintered sparger brewing carbonation wort aeration wands (Pure Oxygen) system for homeb...

HENGKO SS air stone is commonly used to aerate the wort before fermentation, which helps ensure a healthy start to the fermentation process. The HENGKO 2.0 m...

View Detail -

Sintered Metal Sparger of Stianless Steel Porous Sparger Types for Home Brewing Device

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe ...

View Detail

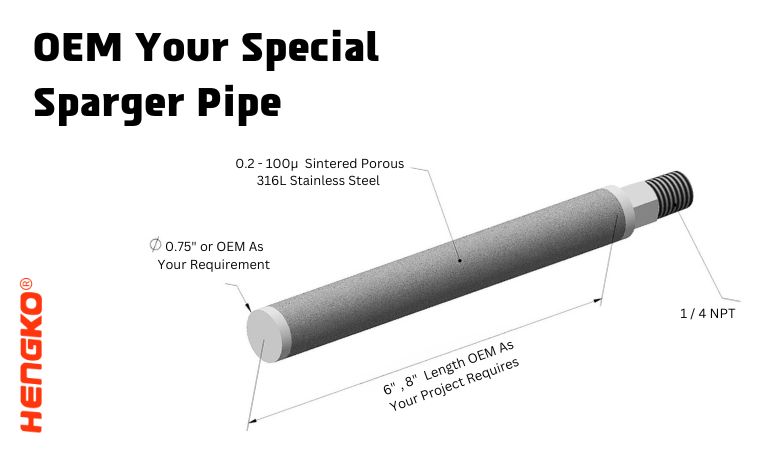

Main Features of Sparger Pipe

A sparger pipe is a type of pipe used in a variety of industrial applications, particularly in the chemical and petrochemical industries.

It is main used for the injection of gas into a liquid, typically to facilitate a chemical reaction or for other process requirements.

As following are some of the features of a sparger tube, please check it.

1. Material:

Sparger pipes are typically made from stainless steel or other corrosion-resistant materials.

This is important because they are often used with aggressive chemicals and must withstand harsh operating conditions.

2. Design:

The design of a sparge pipe is critical to its effectiveness.

It typically includes a series of small holes or perforations along the length of the pipe to allow gas to escape and disperse into the liquid.

The spacing and size of the holes can be customized based on the specific process requirements.

3. Size:

The size of a sparger pipe can vary depending on the application, but they are generally smaller in diameter than other types of pipes used in the same process.

This is because the gas injected through the sparger tube must be finely dispersed into the liquid for optimal results.

4. Connection:

Sparger pipes can be connected to a variety of other equipment and piping systems.

They may be threaded, welded, or connected with flanges, depending on the requirements of the process.

5. Cleaning:

Because sparger pipes are used in processes involving chemicals and other materials, they must be regularly cleaned to prevent buildup and corrosion.

They can be cleaned with mechanical means, such as brushing or blasting, or with chemical solutions.

Overall, sparger tubes play a critical role in many industrial processes, and their design and construction must be

carefully tailored to each specific application to ensure optimal performance and efficiency.

Sparger Pipe Classify

Sintered metal sparger pipes can be classified based on various criteria. Here are some possible classifications:

-

Based on the Type of Gas Introduced:

- Oxygen

- Nitrogen

- Carbon dioxide

- Argon

- Other gas sparger pipes

-

Based on the Shape or Design:

- Straight design

- U-shaped pipe

- Coiled tube

- Other shaped pipes

-

Based on the Porosity:

- Low porosity sparger tube (less than 30%)

- Medium porosity pipe (30-50%)

- High porosity sparge pipe (more than 50%)

-

Based on the Application:

- Wastewater treatment sparger pipe

- Fermentation sparger tube

- Chemical processing sparge pipe

- Pharmaceutical production sparger pipe

- Other industrial sparger system

-

Based on the Materials:

- Stainless steel sparger pipe

- Hastelloy sparger tube

- Inconel sparge pipe

- Other alloy sparger pipes

Note that these classifications are not exhaustive and other criteria can also be used to classify sintered metal sparger pipes.

Application

Sintered metal sparger pipes have a wide range of applications in various industries, including:

1. Wastewater Treatment:

2. Fermentation:

3. Chemical Processing:

4. Pharmaceutical Production:

5. Food and Beverage Production:

6. Environmental Monitoring:

7. Petroleum and Gas Production:

8. Metal Refining:

FAQ for Sparger Pipe

1. What is a Sparger Pipe?

In Short, A Sparger Pipe is a porous metal pipe that is used to introduce gases into a liquid for various industrial applications. The pipe is typically made from sintered Porous stainless steel or other metal like alloys, and features a highly porous structure that allows gases to diffuse evenly into the liquid. and also can easy to OEM the pore size of the metal, to meet sparger system requirements.

2. What are some common applications of sparger tube?

Sparger pipes are commonly used in applications such as wastewater treatment, fermentation, chemical processing, and pharmaceutical production. They can be used to introduce oxygen or other gases into liquids, and can also be used for mixing and dispersion.

3. What types of gases can be introduced using a sintered metal sparge pipe?

A sintered metal sparge pipe is a device used to introduce gases into a liquid or solid material. It's made from metal particles that have been fused together, creating a porous structure that allows gas to flow through it. This can be used in various applications such as in the brewing, pharmaceutical, chemical, and wastewater treatment industries. Here are some common types of gases that can be introduced using a sintered metal sparge pipe:

1. Air: Often used in aeration processes to promote biological activity or to mix substances.

2. Oxygen: Used in biological treatment processes, fermentation, and other applications where increased oxygen levels are required.

3. Carbon Dioxide: Commonly used in the beverage industry for carbonation, as well as in pH control in various chemical processes.

4. Nitrogen: Used in applications where an inert atmosphere is required, such as in the preservation of food or in some chemical reactions.

5. Hydrogen: Can be used in hydrogenation processes in the chemical industry.

6. Steam: Though not a gas in itself, steam can be introduced through sintered metal sparge pipes for heating or other process needs.

7. Chlorine: Used in water treatment processes for disinfection.

8. Argon: Another inert gas, used in applications where reactions with the surrounding materials must be minimized.

9. Helium: Used in leak detection and other specialized applications.

10. Specialty Gases: Various other gases tailored to specific industrial needs can also be introduced through sintered metal sparge pipes, depending on the compatibility with the materials and the specific requirements of the process.

It's essential to note that the compatibility of the gas with the material of the sintered metal sparge pipe must be considered, as some gases might react with certain metals. The design, including pore size and distribution, must also be suitable for the specific gas and application to ensure efficient distribution and to prevent clogging or other operational issues.

4. What is the porosity of a typical sintered metal sparger pipe?

The porosity of a sintered metal sparger pipe can vary depending on the specific application and the requirements of the user. Generally, porosities range from 20 to 60% by volume.

5. How is a Sparger Pipe made?

Sintered metal sparger tube are made using a process called powder metallurgy, which involves pressing metal powder

into a specific shape and then heating it to a high temperature to create a solid, porous structure.

A sparger pipe is a device used to introduce gases into liquids, often used in industrial applications such as fermentation, chemical processing, or wastewater treatment. The manufacturing process for a sparger pipe can vary depending on the specific design and application, but here's a general overview of how a sparger pipe might be made:

1. Material Selection: The material must be chosen based on the application and the type of gas and liquid involved. Common materials include stainless steel, titanium, or specialized alloys that resist corrosion.

2. Design and Planning: The design of the sparger pipe will depend on the specific application. It may include multiple small holes or nozzles to ensure even distribution of the gas. The design is often done using CAD (Computer-Aided Design) software.

3. Cutting and Shaping: The selected material is cut and shaped into the desired form. This may involve processes like laser cutting, plasma cutting, or water jet cutting to create the main body of the pipe.

4. Drilling or Punching Holes: Small holes or nozzles are created in the pipe to allow the gas to escape into the liquid. This can be done through drilling, punching, or other specialized techniques.

5. Welding and Assembly: If the sparger pipe consists of multiple parts, they are assembled and welded together. This may include attaching flanges, fittings, or other components.

6. Surface Treatment: Depending on the application, the surface of the sparger pipe may be treated to enhance its properties. This could include polishing to create a smooth surface or applying a coating to increase resistance to corrosion.

7. Testing and Quality Control: The finished sparger pipe is tested to ensure that it meets the required specifications. This may include pressure testing, leak testing, and inspection for defects.

8. Packaging and Shipping: Once the sparger pipe has passed all quality control checks, it is packaged and prepared for shipping to the customer.

9. Installation: Depending on the complexity, the sparger pipe may require professional installation. This could involve integrating it into existing piping systems, ensuring proper alignment, and making necessary connections.

10. Maintenance and Monitoring: Regular maintenance and monitoring may be required to ensure that the sparger pipe continues to function effectively. This could include regular cleaning, inspection, and replacement of worn parts.

The exact process can vary widely depending on the specific design of the sparger pipe and the requirements of the application. Custom sparger pipes may require specialized manufacturing techniques and additional steps to meet unique specifications.

6. What is the maximum operating temperature of a Sparger Tube?

The maximum operating temperature of a sintered metal sparger tube depends on the specific alloy used to manufacture the pipe. Generally, they can operate at temperatures up to 800°C (1472°F).

7. What is the maximum operating pressure of a sintered metal sparger pipe?

The maximum operating pressure of a sparger pipe depends on the specific design of the pipe and the materials used. Generally, they can operate at pressures up to 10 bar (145 psi).

8. How long do sintered metal sparger tube typically last?

The lifespan of a sintered metal sparger pipe depends on the specific application and the conditions in which it is used. Under normal operating conditions, they can last for several years.

9. Can sintered metal sparge pipes be cleaned?

Yes, sintered metal sparger tube can be cleaned using a variety of methods, including backwashing, ultrasonic cleaning, and chemical cleaning.

10. Can sintered metal sparger tube be sterilized?

Yes, sintered metal sparge pipes can be sterilized using a variety of methods, including autoclaving, gamma irradiation, and chemical sterilization.

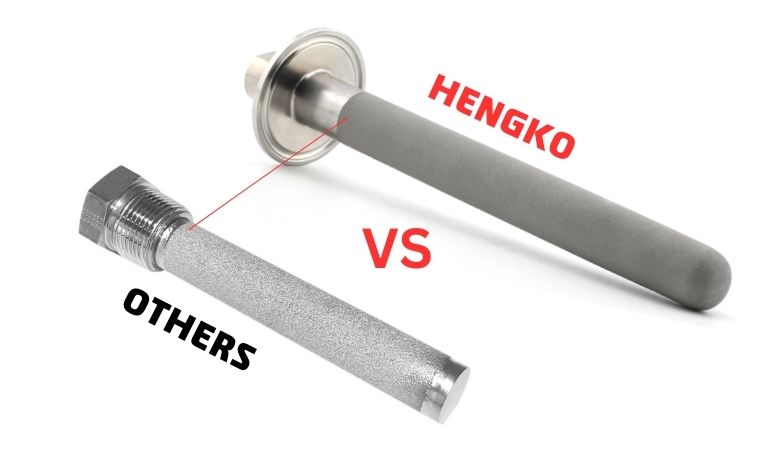

11. What are the advantages of using sintered stainless steel sparger pipes?

Sintered stainless steel sparger pipes are widely used in various industries for introducing gases into liquids or other materials. They offer several advantages that make them suitable for different applications:

1. Durability: Stainless steel is known for its resistance to corrosion and wear. This makes sintered stainless steel sparger pipes long-lasting and suitable for use with various chemicals and in different environmental conditions.

2. Uniform Gas Distribution: The porous structure of sintered stainless steel allows for a uniform distribution of gas. This can lead to more efficient mixing or reaction, depending on the application.

3. Temperature Resistance: Stainless steel can withstand high temperatures, making these sparger pipes suitable for processes that require heating or are conducted at elevated temperatures.

4. Chemical Resistance: Stainless steel is resistant to a wide range of chemicals, making these sparger pipes suitable for use in various chemical processes without the risk of corrosion or other reactions with the material.

5. Customizable Pore Size: The sintering process allows for control over the pore size and distribution in the material. This means that the sparger pipes can be customized to suit specific applications, whether that requires fine bubbles for gentle mixing or larger bubbles for more vigorous agitation.

6. Ease of Cleaning: The smooth surface of stainless steel makes it easy to clean, which is particularly important in industries like food processing or pharmaceuticals where hygiene is a critical concern.

7. Pressure Resistance: Sintered stainless steel sparger pipes can withstand high pressures, making them suitable for applications that operate under substantial pressure without the risk of failure.

8. Compatibility with Various Gases: As mentioned earlier, these sparger pipes can be used with a wide range of gases, from air and oxygen to more specialized or reactive gases.

9. Cost-Effectiveness: Although the initial cost might be higher compared to some other materials, the durability and low maintenance requirements of sintered stainless steel can make it a cost-effective choice in the long run.

10. Environmentally Friendly: Stainless steel is recyclable, and the long lifespan of these sparger pipes also contributes to their environmental sustainability.

11. Scalability: Sintered stainless steel sparger pipes can be manufactured in various sizes and shapes, making them suitable for both small-scale laboratory applications and large-scale industrial processes.

In summary, sintered stainless steel sparger pipes offer a combination of durability, efficiency, and versatility that makes them suitable for a wide range of applications. Their resistance to corrosion, ability to withstand high temperatures and pressures, and customizable properties contribute to their popularity in various industries.

12. What are the disadvantages of using sintered metal sparge pipes?

Some of the disadvantages of using sintered metal sparger tubes include their high initial cost, susceptibility to clogging or fouling, and the potential for corrosion if not made from the correct alloy.

More questions about the sintered metal sparger pipes, you are welcome to contact us by email ka@hengko.com, we are pleasure to supply

you best solution for your special project and applications.