316 L Powder Stainless Steel Metal Frit Spargers Building A Stainless Steel Filtering System For Beer Ferment

Product Description

Product Description

This device is particularly good for fermentations that require a large population of yeast. Pilsners (or other beers fermented at low temperatures) or high-gravity beers in particular will really benefit from getting high levels of oxygen into the wort at the start of fermentation.

The wand kit includes the 40cm stainless steel 1/2''mm OD wand and the aeration stone screws into the end using a very fine (typically 0.5-2 micron) aerator at one end so it can easily be removed for autoclave or cleaning in acid solution.

These are immersed directly in the fermenter right before you pitch your yeast. In a relatively short time of 60-90 seconds, you can reach the ideal 9-12 ppm for most words, though a very high gravity wort (1.080 or higher) might take a little longer.

Specifications:

400mm total wand length

0.5-2 micron stainless sintered air stone

MAXIMUM SURFACE AREA FOR MASS TRANSFER

THE RIGHT SPARGER FOR YOUR APPLICATION To determine the right size of the sparger for in-tank or vessel sparging you need to know :

gas flow

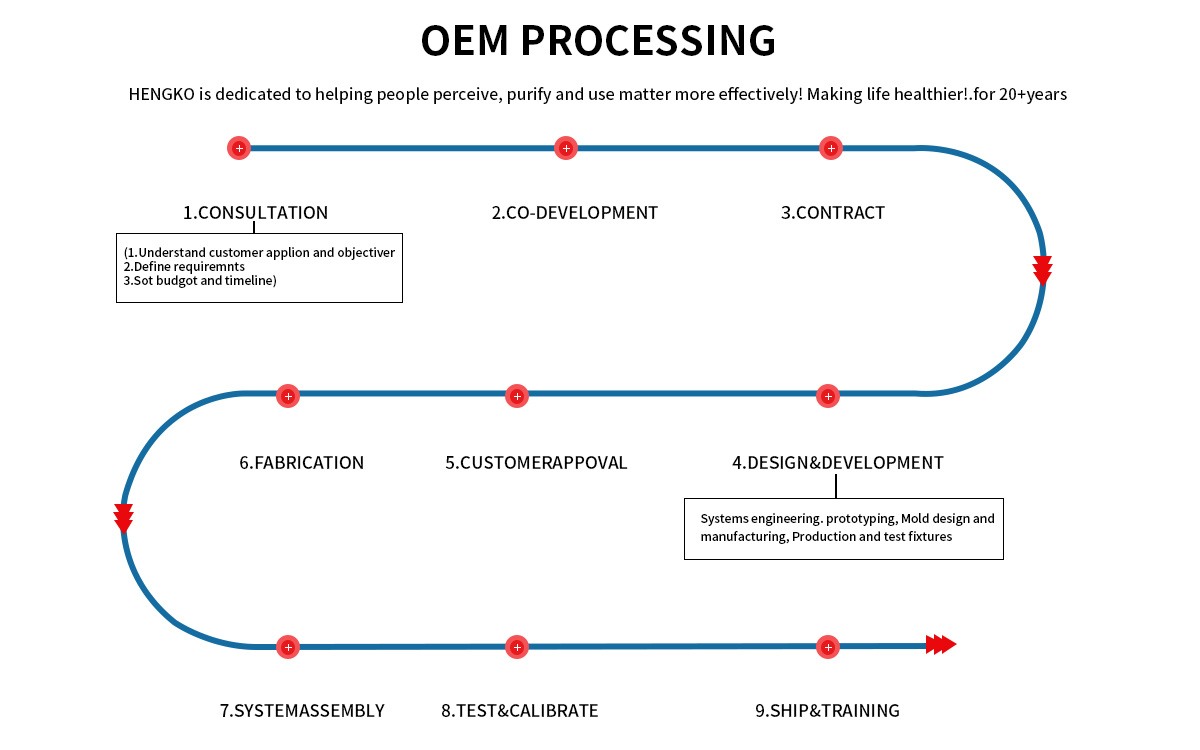

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!