-

Biopharmaceutical purification and filtration porous filter plate 10um 20um 50um

A porous filter plate is a new type of high-efficiency porous filter material made of metal stainless steel powder through powder sieving, moulding, sinterin...

View Detail -

Porous sintered metal filter of ozone and air in water

The manufacturing process of large diameter (80-300 mm) discs of sintered stainless and corrosion-resistant steels is described. The characteristics of the i...

View Detail -

Sintered Porous Metal Leaf Disc Filter For the Polymer Melt Industry

Leaf Disc and Solid Plate Filters for critical hot melt polymer filtration applications. Leaf disc and solid plate filters are designed for critical h...

View Detail -

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion Unlock the Versatility of Sintered Metal Elements with HENGKO! Our sintered meta...

View Detail -

Multi-layer sintered stainless steel mesh plate fluidized bed equipment Distributor bot...

Stainless steel mesh plate for fluid bed Control of gas distribution, powdered material transmission, and fluidization operation has been widely used in indu...

View Detail -

316 304 stainless steel plate – Sintered porous metal filter alien media

HENGKO stainless steel plate filters are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been ...

View Detail -

Corrosion resistant microns 316L stainless steel porous sintered filter metal sheets / ...

Product Describe HENGKO porous metal gas diffusion layers are the leading choice for high performance electrolyzer and fuel cell applications. The uniform po...

View Detail -

Easy Clean Micron Porous SUS Sintered 316L Stainless Steel Inline Metal Sheet Plate Rou...

The sintered porous metal sheets having high porosity were obtained from metallic powders by free spreading methods followed by sintering. The sintered struc...

View Detail -

0.2 5 10 40 Micron porous sintered powder stainless steel 316L metal plate filter for c...

The porous materials sintered plates obtained in layers by free spreading, compaction, and sintering metallic powders are used as a semi-product to obtain fi...

View Detail -

Customized 2 10 20 60 Micron Porous Sintered Stainless Steel 316L Metal Plate Filter

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Customized sintered powder SS 316L stainless steel filter disc, 0.2 5 7 10 30 40 50 70 ...

HENGKO stainless steel filter disc is made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been wid...

View Detail -

5 10 30 60 90 microns powder micro porous sintered metal sheet filter

Sintered metal filter sheets are widely used for removing foreign particles from many different kinds of flow media. Major application fields: General gases,...

View Detail

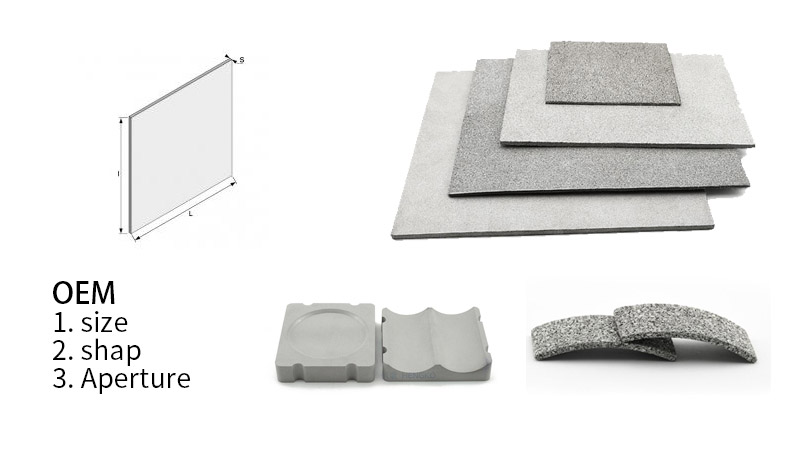

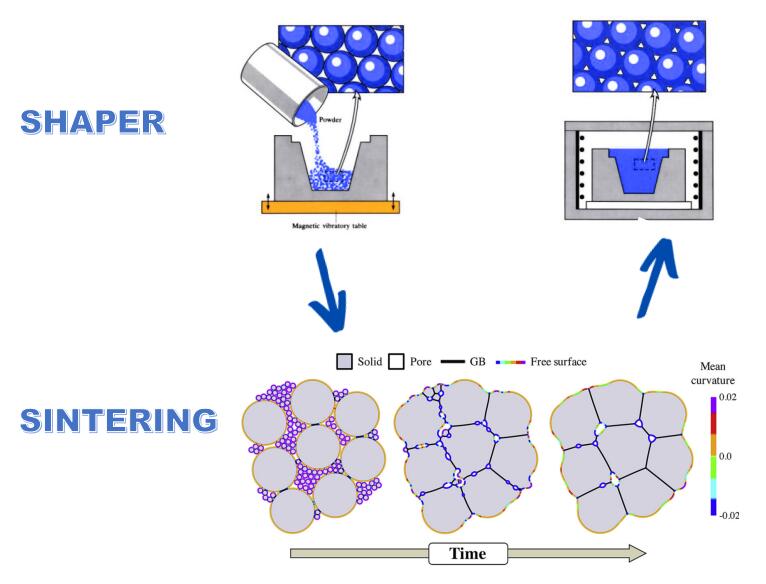

How Does Sintered Stainless Steel Filter Plate Production :

In Short, There are Two Steps:

1.) Stamping Shape and Size as Your Design

2.) High-Temperature Sintering

The Sintered Stainless Steel Filter Plate Can Customize for various shape and specifications. The plate can design to

be regular rectangular, square pieces, to stamp in the module and then can also be processed into

curved pieces, sure can customize size and Aperture, also can be designed to sintering together with

aluminum or stainless steel housings, you can easy to Customized such as Customized Length, Width,

Height/ Thickness, Aperture, Alloys, and Media Grades, can be altered to meet various filtration, flow,

and chemical compatibility requirements for your product or project.

Main Features & Benefits of Sintered Filter Plate:

Porous metal plate can be offered in different thicknesses from 2 to 100 mm.

1.) High mechanical strength,

well suited for high differential pressures and flow rates

2.) Good durability against most aggressive fluids,

3.) Usable over a wide range of temperatures,

4.) High mechanical resistance

5.) Regenerable through back flush/chemical / thermal or ultrasonic treatment.

6.) Good Rigidity

7.) Plasticity,

8.) Oxidation resistance

9.) Corrosion Resistance

10.) No need for additional skeleton support protection

11.) Simple installation and use

12.) Easy maintenance, and exemplary assembly.

13.) It can be Welded, bonded, and machined.

If you have high requirements for the filtration area, HENGKO professional engineer team will

design solutions for you to meet your high requirements and standards.

HENGKO has a professional technical team to provide technical support and can design customized

products on demand and with drawings and samples. Due to the many specifications and sizes,

we cannot identify the specific prices individually; the above prices are for reference only; don't hesitate

to contact customer service before placing an order.

Application of Stainless Steel Plate Filter :

Stainless Steel Filter Plate filters are suitable for distillation, absorption, evaporation, filtration, and other

processes in petroleum, refining, chemical, light industry, pharmaceutical, metallurgy, machinery, ship, automobile

Tractors and other industries eliminate droplets and liquid foam entrained in steam or gas.

Stainless Steel Filter Plate filters are versatile and can be used in various applications in different industries. Here are some of the most common applications of Stainless Steel Plate Filters:

1. Liquid Filtration: These filters remove impurities and contaminants from liquids in different industrial processes. They are used in the food, beverage, chemical, and pharmaceutical industries.

2. Fluidizing: Stainless Steel Plate Filters are used in fluidizing applications, where they help to control the flow of fluids, such as air and gases.

3. Sparging: These filters are used in sparging applications, which help introduce gases into liquids for mixing, reactions, and aeration.

4. Diffusion: Stainless Steel Plate Filters are used in diffusion applications, where they help to spread and disperse gases and liquids in different industrial processes.

5. Flame Arrestor: These filters are used in flame arrestor applications, which help to control and prevent the spread of fire and flames in different industrial processes.

6. Gas Filtration: Stainless Steel Plate Filters are used in gas filtration applications, which help remove impurities and contaminants from gases.

One typical application of Stainless Steel Plate Filters is fluidized bed plate applications, which help to control the flow and movement of gases and liquids in fluidized bed processes. Overall, Stainless Steel Plate Filters are essential in ensuring various industrial processes' quality, safety, and efficiency.

Engineered Solutions

Over the Past Ten Years, HENGKO has solved extremely complex filtration and flow control questions in various industries.

for customers Worldwide. Fast to Solving complex engineering tailored to your application is our mission and target,

You Are Welcome to Share Your Project and Work with HENGKO; we Will Supply Best Professional Porous Metal Filter

Solution For Your Projects.

You Can Send Email by ka@hengko.com, We Will Send Back Within 24-Hours.

How to Customize Sintered Porous Metal Plate

Welcome to contact HENGKO to work together to find the best solution for your special design or requirements

for the stainless steel filter plate or sheet.

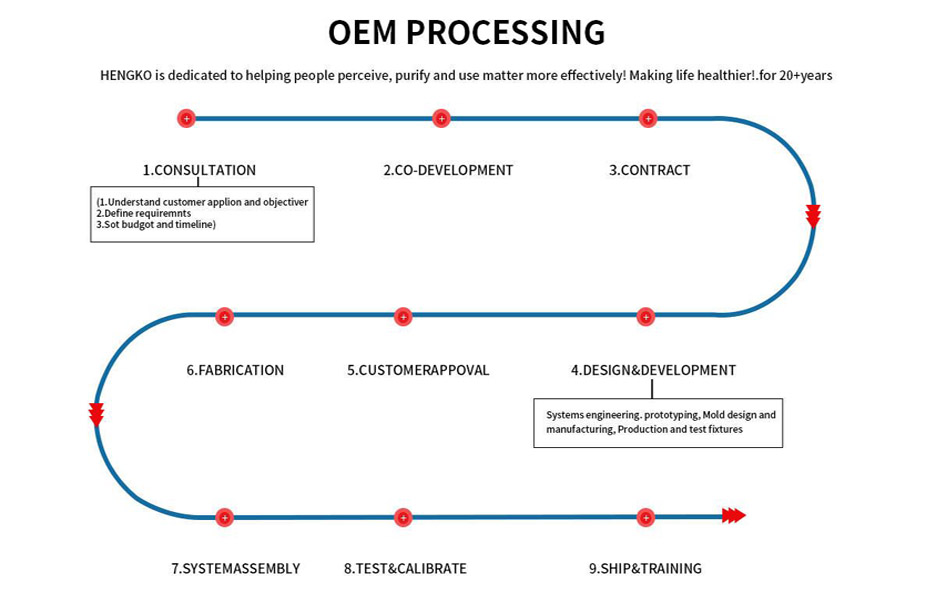

Here is the O.E.M Porous Metal Filter Process.

Please Check it and Contact us to talk more details.

HENGKO is a company with a mission to help people perceive, purify, and use matter more effectively, promoting a healthier life for all. Over the past 20 years, HENGKO has been dedicated to providing quality products and services to its customers. Here is a detailed description of the different steps involved in their process:

1. Consultation and Contact HENGKO: HENGKO has a team of professionals available to provide customers with consultation and guidance to help them choose the right products and services that suit their specific needs.

2. Co-Development: HENGKO works with clients to develop innovative solutions that fit their specific requirements. The team collaborates with the customers throughout the co-development process to ensure that the final product is tailored to their needs.

3. Make a Contract: Once the specifications and requirements are finalized, HENGKO will prepare a contract that outlines the terms and conditions of the project, including the price, delivery date, and other relevant details.

4. Design & Development: HENGKO has a team of experts specializing in the design and development of sintered stainless steel and porous materials. They use advanced software and tools to create 3D models and prototypes that meet the customers' requirements.

5. Customer Approval: Before proceeding with fabrication and mass production, HENGKO ensures that the customers approve the design and specifications of the final product.

6. Fabrication/Mass Production: After receiving the approval, HENGKO moves forward with the fabrication and mass production of the sintered stainless steel and porous materials. They use state-of-the-art manufacturing processes to produce high-quality products that meet the client's requirements.

7. System Assembly: HENGKO's team of experts assembles the product with great care, ensuring that all components fit precisely and work seamlessly together.

8. Test & Calibrate: Once the product is assembled, HENGKO conducts thorough testing and calibration to ensure that the product meets the highest standards of quality and performance.

9. Shipping & Training: HENGKO ensures that the product is delivered to the customers on time and provides comprehensive training on using and maintaining the product to achieve optimal performance.

Why HENGKO Stainless Steel Filter Plate Filters

HENGKO offers a range of customizable and innovative sintered stainless steel plate filters for various applications.

Our products are widely used in industrial filtration, pressure regulation, sensor protection, and more. We provide

high-quality production, unique designs, and expert support in various industries. With over 50+ countries served,

we are an industry-renowned manufacturer and seller of porous metal plates. At HENGKO, we have a team of

professional technical experts dedicated to developing and producing high-requirement sintered stainless steel

and porous materials, supported by a key laboratory and academy in universities both domestically and internationally.

✔ PM Industry-renowned manufacturer and sales of porous metal plate over 50+ countries

✔ Unique designs with different size, materials, layers and shapes

✔ High quality producing as CE and ISO9001 standard, Stable Shape, Meticulous Work

✔ Before and Aftersales Service with Engineer Team Support Directly and Fast Solution

✔ Full Expertise in various applications in chemical, food, and beverage industries

HENGKO, One of the Experienced Enterprises, provides sophisticated Sintered Stainless Steel Plate Filter elements.

We have professional technical teams focused on developing and manufacturing high-requirement sintered stainless steel and

porous materials. There are high-tech enterprises, Key Laboratory, and an academy in university at home and abroad in HENGKO.

Popular FAQ List About the Sintered Filter Plate

1. What is Stainless Steel Filter Plate ?

In short, Stainless Steel Filter Plate is one of the Plate Shape Filters Made of Sintered Stainless Steel or Stainless Steel Wire Mesh.

Normally, Can Customize the size and pore size of the filters as your requirement for flow, temperature, and pressure requirements.

2. What Types of Metal used for Stainless Steel Plate Filter ?

Normal, the First we use 316 or 316L stainless steel, because 316L is food class, and price is accept, but

the function is the best than normal metal like bronze.

Second, if have very high requirement for the filtration, Then we will choose Inconel powder, copper powder,

monel powder, and pure nickel powder, as your project requires.

3. What is the Difference Between Porous and Non-porous?

Simple to say, the difference between porous and non-porous is if the gas or liquid can pass through the filters.

4. Where to Use a Porous Metal Plate?

For the Porous Metal Plate / Sintered Stainless Steel Plate, As Experience, Main Used to As Follow Industries:

A.) Conductivity

High conductivity remains in porous metal. Because of its high surface area and conductivity, it is studied to apply as fuel cell electrodes.

Studies about its application for fuel cells are ongoing.

B.) Ventilation

Open cell type porous metal is connected to the voids and has fluid permeability. For this characteristic, applications such as catalyst filters and impurity filtration membranes are researched.

C.) Thermal conductivity

Because of Utilizing high surface area and thermal conductivity, it is researched for heat exchange applications.

D.) Energy Absorption

The application of the heat exchanger is being investigated.

Since closed cell type porous metal is lightweight yet retaining its strength, it is researched for practical use as energy absorbing (shock absorbing) material for automobiles.

E. ) Sound insulation

Porous metal for crush box in automobile

Closed cell type porous metal has excellent sound insulation and absorption because of its layers of independent cells.

F. ) Gas Storage

G.) Various filtration

H.) Various flow control

5. How is the sintered stainless steel filter plate manufactured?

About the question What Is Sintered Stainless Steel Filter or How the sintered filter manufactured, please check our

Blog details to What Is Sintered Metal Filter.

6. Who Can Supply High-Quality Sintered Filter Plates in China?

As one of the full experience and focus on sintered metal filter industry over 20 years, HENGKO is the one

of the best factory who can supply you various high-quality sintered metal filters, can custom as your project

Our R&D Team can supply the best solution to your requirements for any sintered metal products.

You are Welcome to Contact us if still have any questions for the Stainless Steel Filter Plate.

you can also send email by ka@hengko.com. we will send back with advice and solution within 24-Hours.