-

Sintered micron stainless steel porous metal filter cylinder for gas filtration

Product Describe Sintered Metal Filter Cartridges: Porous metal filters have a wide variety of industrial filter uses. These reusable, high-quality filters a...

View Detail -

Pharmaceutical Industry Medical Grade Sintered Metal Stainless Steel Filter

Sintered metal filters with dryers and mills within the pharmaceutical industry. When these elements are used with dryers and mills, they are contained withi...

View Detail -

Resists High Temperature Stainless Steel Sintered Powder Filter Element filter cartridg...

Product Describe Sintered powder filter element also named metal porous sintered filter is made of titanium or stainless steel powder. It is a new style of m...

View Detail -

Porous Metal Powder Sintered Stainless Steel Catalyst Recovery Filters for Catalyst Rec...

A brief introduction to the working principle of catalyst filter (sintered filters) equipment: HENGKO Sintered Metal Catalyst Filter uses catalysts to recove...

View Detail -

HENGKO Superior Membrane Surface Porous Sintered Metal Filter

Product Description:Upgrade your filtration efficiency and prolong the lifespan of your filters! HENGKO's sintered porous stainless steel filter product util...

View Detail -

HENGKO OEM Sintered Steel Filter and Sparger

OEM Sintered stainless steel diffuser / sparger, for aerating in liquid. HENGKO’s sintered sparger are unsurpassed in strength, precision and uniformity. The...

View Detail -

OEM Fiber Collimator Diameter 7mm Fiber Porous Metal Stainless Steel Filter

This product can be used for fiber collimation or for coupling focusing. The use of collimation, either single mode or multimode fiber can be used. If used a...

View Detail -

Stainless Steel Sintered Porous Metal Filter Tubes Porosity Down to 0.2 µm – In F...

Pore size:0.2-100microns Materials: SS Metal Porosity:30%~45% Working Pressure:3MPa Operating Temperature:600℃ Applications for sintered porous metal ...

View Detail -

Stainless Steel Sintered Metal Filters – Applications of Filtration in the Pharma...

Filtration through sintered metal filters is used in pharmaceutical manufacturing to remove unwanted material from the formulated bulk solution. The primary ...

View Detail -

HENGKO Customized 316L Powder Sintered Porous Metal Stainless Steel Filter With Externa...

Products Description The stainless steel muffler is a muffler made of all stainless steel or with a stainless steel tube or outer shell. HENGKO stainless s...

View Detail -

Sintered Porous Metal Stainless Steel Filter Tube for Fiber Optic Collimator HENGKO

Product Describe porous metal cartridges can be customized for a wide variety of applications and specifications and can be attached to metallic and non-meta...

View Detail -

Sintered Stainless Steel Filter Cartridges for Drug Manufacturing Process Filtration

Porous sinter metal cartridges, often with customized connectors (Sometimes connectors are not added in certain application scenarios), are used to separate ...

View Detail -

HENGKO Sintered Filter Cartridge for Process Gas and On-Line Analysis

Gas and Sample Filtration For process Gas and On-Line Analysis The filtration of gases is essential in a vast range of applications, yet only three m...

View Detail -

High performance porous sintered metal stainless steel isostatic filters tubes support ...

Stainless steel sintered tubes are made of stainless steel powder, processed by sintering technology. This product can purify the contaminated media and achi...

View Detail -

Cylindrical 25 50 micron stainless steel microns porous powder sintered filter tube for...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

316L Sintered stainless steel filter cartridge for gas solids separation

Filtration systems utilizing sintered metal filter elements have proven to be an effective and economical alternative to other separation equipment susceptib...

View Detail -

Porous metal filter tube for thermal management refining and specialty chemical | HENGKO

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Professional manufacturer customized sintered porous metal filter tube used for medical...

HENGKO sintered filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration cooling...

View Detail -

sintered filter stainless steel filter cylinder for water treatment aeration/dust extra...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

0.2um to 90 micron 5 – 100mm height powder or wire mesh porous sintered metal sta...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail

Main Features of Sintered Metal Tube Filters:

1. High Mechanical Strength

2. Good Rigidity

3. Plasticity

4. Oxidation Resistance,

5. Corrosion Resistance,

6. No Need for Additional Skeleton Support Protection,

6. Simple Installation and Use

7. Easy Maintenance, and Exemplary Assembly.

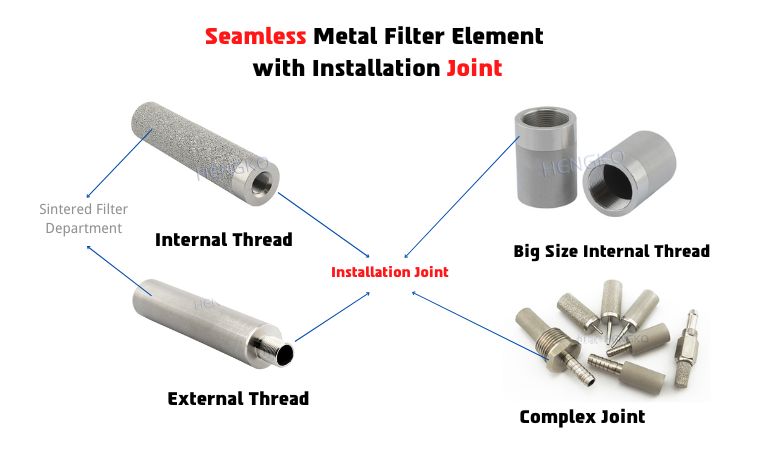

8. It Can be Customized to Seamlessly Connect

Sintered Filter Elements with Screw Joints

So If you Have High Requirements for the Filtration Elements such as Sintered Metal Tube, Sintered Metal Disc,HENGKO's

Professional Metal Filtration Engineer Team Will Design Solutions for You ASAP to Meet Your Devices or Projects Needs.

Application of Sintered Metal Tube Filter :

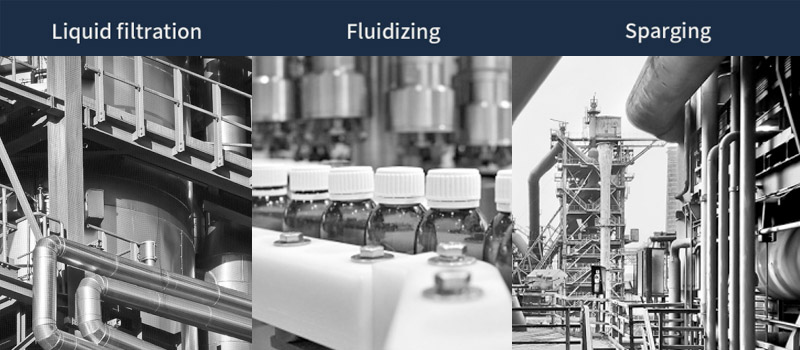

Powder Porous Metal Tubes Filters are suitable for distillation, absorption, evaporation, filtration, and other processes in petroleum, refining, chemical, light industry, pharmaceutical, metallurgy, machinery, ship, automobile tractor, and other industries to eliminate droplets and liquid foam entrained in steam or gas.

1. Liquid Filtration

2. Fluidizing

3. Sparging

4. Diffusion

5. Flame Arrester

6. Gas Filtration

Engineered Solution Support

Over the Years, HENGKO Has Solved Extremely Complex Porous Metal Tubes Filtration and Flow Control Problems

in a Wide Range of Industries Over the World.

We Are Pleasure to help You to Solving Complex Engineering Tailored to Your Applications.

Welcome to Share Your Project and Work with HENGKO, We Will Supply Best Professional Metal Filter Solution For Your Projects.

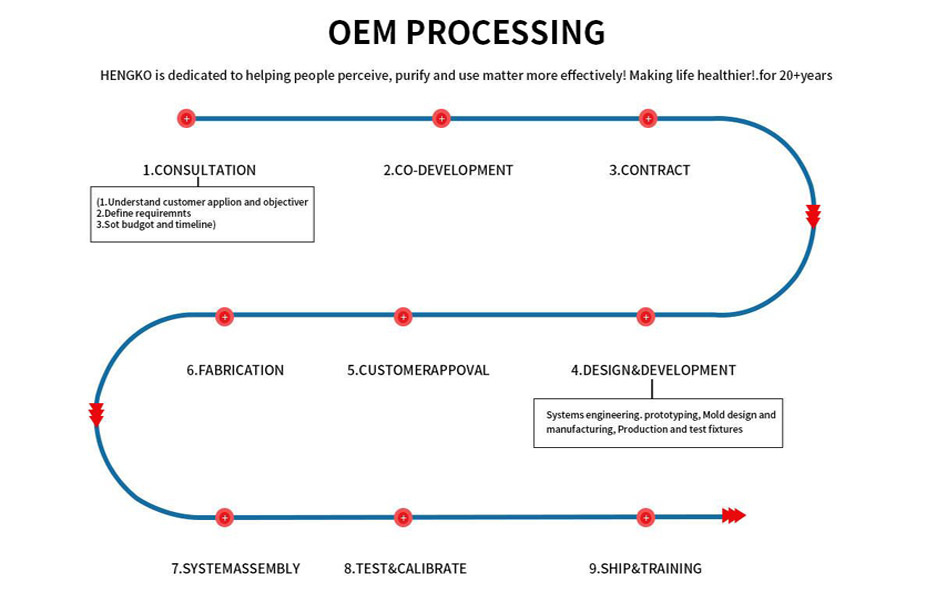

How Customize Stainless Steel Filter Tube With HENGKO

When You have some Special Requirements about Stainless Steel Filter Tube for projects and can not find the same or

similar Filter products, You are Welcome to contact HENGKO to share your specification details for the sintered stainless

steel filters, So we can try our best to find the better solution for your project and here is the process of OEM Porous Metal Tubes,

Please Check it and Contact us talk more details.

1. Consultation and Contact HENGKO

2. Co-Development

3. Make a Contract

4. Design & Development

5. Customer Appovaled

6. Fabrication /Mass Production

7. System Assembly

8. Test & Calibrate

9. Shipping

Why Work With HENGKO for Porous Metal Tubes Filters

HENGKO Support Various Different requirements for sintered stainless steel tubes with customizable and innovative designs as clients' requirements

Our Porous Metal Tubes have a long-standing history of being commonly used in many applications like superior industrial filtration, dampening,

sparging, sensor protection, pressure regulation, and many other applications.

✔ PM Industry-renowned manufacturer of Stainless Steel Filter Tube in China

✔ Unique customized designs as different size, materials, layers and shapes

✔ High quality products strictly as CE standard, Stable shape, Meticulous work

✔ Service from Engineering up to aftermarket support, fast solution

✔ Expertise in various applications in chemical, food, and beverage industries

HENGKO, One of Experienced Enterprises that provides sophisticated sintered stainless tube filter element enterprises.

We have professional technical teams that focused on developing and manufacturing high requirement sintered stainless

steel element and porous materials . There are high-tech enterprises, Key Laboratory and academy in university at home

and abroad in HENGKO.

Faq Guide for Sintered Metal Tube

if you want to know more information about sintered porous metal tube, then you come right place,

here bellow, we list some popular questins about sintered stainless stell tube,

This guide explores all the fundamental aspects of sintered metal tube filters, such as material grade,

features, benefits, surface finishes, pore size, and sizes,enjoy it.

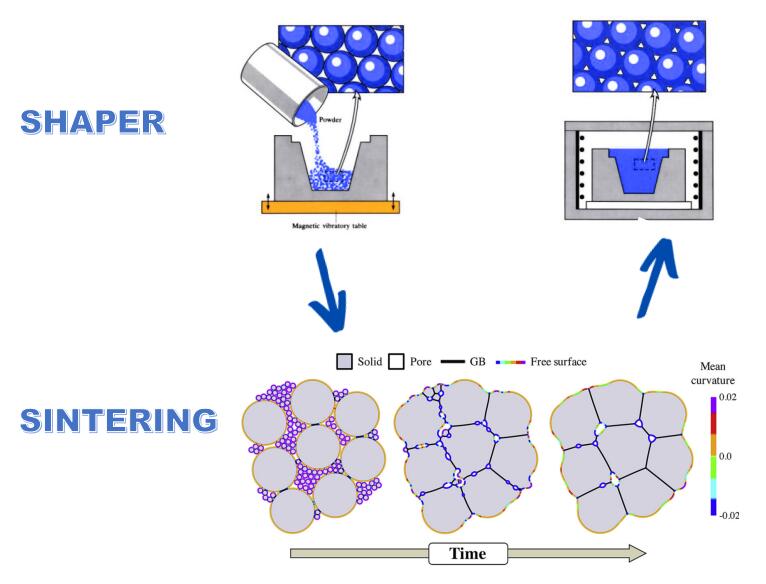

1. What is Sintered Metal Tube ?

In a nutshell, The sintered metal tube is made of stainless steel powder metal, to stamp tube shape

and sintering by the high temperature of over 300°. The sintered metal tubes are now mainly for

industrial applications such as gas and liquid filtration in the petroleum and pharmaceutical industries.

2. What Are the Main Features of Sintered Metal Tube ?

Sintered metal tubes have unique features that boost their performance in industrial applications.

Here are some of the features of sintered metal tubes that you should know.

1. Wide variation of filtration rating ranges between 1 micrometer and 200 micrometers.

2. Great mechanical strength with the capability of maintaining better filtration performance under pressure.

3. Simple design that increases ease of cleaning, especially backwashing

4. Easy to install and replace

5. Durable and cost-saving

3. What Materials Can Sintered Metal Tube Made of ?

You Can Have Many Metal Powder or Metal Mesh options to Manufacture the Sintered Metal Tube.

1. One of the metal powder materials you can check in the market is stainless steel, which shows

very high mechanical strength and corrosion resistance. Because Stainless steel has stably and

good physical properties, it can work under very high temperatures and pressure without damage.

2. Except for stainless steel powder, you can also use bronze materials with great corrosion resistance.

It is also one of the best option for most cost-effective material for manufacturing sintered metal tubes.

However, for bronze, there are very obvious disadvantages because of quite weak and does not have

the great mechanical and tensile strength to support high-pressure applications.

3. For some high requirements project, We will choose incorporate nickel and its alloys among the

materials for manufacturing sintered metal tubes. It is among the materials you can use to produce

sintered metal tubes for harsh environments. Despite the efficiency in harsh conditions, you might

have to spend more because they are very expensive.

Summary

A: Stainless Steel is the best cost-save and can reach high metal sintered tube requirements.

Can use to 90% application of filters.

B: For the Bronze, Main for the normal environment and low cost for the project.

C. About the incorporate nickel, main for Harsh environment and ultra-high pressure,

ultra-high temperature environment use.

So hope this can help you to choose sintered metal tubes.

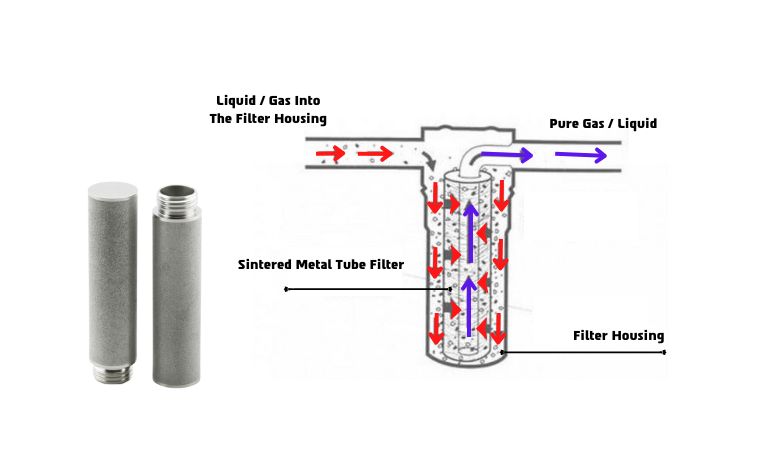

4. What is the Working Principle of Sintered Metal Tube?

How sintered metal tube works

Fluid will pass via the sintered metal tube in line with its position.

Also, the fluid that flows from one end of the sintered metal tube has many contaminants.

A change in pressure will cause a drop as the fluid passes into the sintered metal tube.

When there is a pressure drop, it means the speed of the fluid within the sintered metal tube is low.

It makes the fluid take a long time to pass through the tiny pores of the tube.

The effect of this is that large contaminants will remain behind as the clean fluid passes through to the other end.

Also, one can remove the contaminants in the tube by applying a backwash.

It means the contaminants will leave the tube from the point of entry.

Also, the clean fluid will exit the sintered metal tube from the exit point.

5.Which Factors Affect the Cost of the Sintered Metal Tubes ?

For the Sintered Metal Tubes Price Main Because of 3 factors:

1. Metal Powder cost : 316L or Bronze metal powder price is difference

2. Size of the metal tube:

normal big size will higher, but if too small, also the small

sintered tube price will higher, because it is hard to manufacture

3. Design simple or complex:

Normally More Complex design sintered metal tube price will higher.

Contact us to talk the price detail.

6. How Does a Sintered Metal Tube Work for Your Enquiment ?

For the Sintered Metal Tube, same as other metal filters, it will help you to

filter out pollutants or impurities in gases and liquids, making your target

gases and liquids more pure.

What are the Applications of Sintered Tube ?

You can use the the sintered metal tubes for industrial applications such as filtration

of gas and liquid in the petroleum and pharmaceutical industry.

7.What Are the Available Sizes of Sintered Metal Tube HengKo Can Supply ?

For normal size of sintered metal tube we manufacture is as follow:

OD:4.0-220mm ID: 1.0-210mm

Height: 2.0-100mm

Pore Size: 0.1-90μm

8. What are the Advantages of Using the Sintered Metal Tubes ?

The Sintered Metal Tube Offers Numerous Advantages on Several Levels.

Main Include:

1. Molding

It is possible to shape the sintered metal sheet to make a sintered metal tube per your preference.

Or Make Mold according to the design requirements, then fill them and sinter them into shape.

Also, HENGKO can customize the sintered metal tube filter by seamlessly connecting it with Screw Joints.

Besides, the material is solid and flexible to handle the molding processes.

2. Good Permeability

This Advantage Enables the sintered metal tube to have a proper flow of fluids.

Also, it will only allow the fluids to pass through and block the contaminants.

Pore Distribution

The sintered metal tube has a large distribution of pores on its surface.

These pores will increase the filtration efficiency of the sintered metal tubes.

Stability

The cylindrical shape of a sintered metal tube makes it a stable element.

That means it can cope with pressure from various fluids without changing shape.

Strong Mechanical Strength

It makes it possible to use in extremely harsh environments such as high temperatures and pressure levels.

The strength will enable them to have no damage from such conditions.

Porosity

It is possible to dictate the porosity of a sintered metal tube.

It makes it possible to fit into the application of your need as you can customize the sizes of the pores as your device requires.

Resistance to Corrosion and Thermal Shocks

This device will withstand corrosion and thermal shock during its operation.

It means you can use it in extremely high temperatures and with corrosive chemicals, and no damage will happen to them.

Ease Maintenance

Regular Cleaning and servicing of the sintered metal tube will make it durable.

Besides, cleaning the sintered metal tube filers is easy, and you will not need to shut the machine off for a long time.

9.Is Sintered Metal Tube Filter Strong?

Yes, a sintered metal tube filter is strong as the pressure will form a strong connection known as green strength.

10. How Does Sintered Metal Tube Manufacture ?

You Can Understand How the sintered tube manufacture, one step is to stamp, the second step is to sintering.

11. Why should you lmport Sintered Metal Tubes from China ?

1. Price is Lower than EU or US factory.

2. Technology is almost with the high-end sintered metal filter manufacturing.

3. Some professional sintered metal filter factory like HENGKO have over 20 years manufacturing experience.

12. How Many Pore Sizes of Sintered Metal Tubes Normally to use ?

Normal pore size of the sintered metal tube filter is 0.1-90 μm, and sure you can OEM sintered metal tube filers

any pore size with HENGKO for your special requires of filtration project.

What is the Difference Between the Sintered Metal Tube and Sintered Stainless-Steel Plate ?

Do You Supply Pleated Sintered Metal Tubes ?

What is difference Stainless Steel Filter Tube with sintered Stainless Steel Filter Tube ?

You Are Welcome to Contact Us by Email ka@hengko.com if Still Have Any Questions

About the Sintered Metal Tube Filters.