-

High Pressure Snow Foam Generator Mesh Filter

High-pressure snow foam lancer compressed knitted wire mesh filter High pressure foam maker and foam generator nozzles assembly in Snow Foam Lance. The foam ...

View Detail -

Tobacco Pipe Filter Stainless Steel 304 316 Mesh Screen Filter

Cigarette mesh filter disc is also called cigarette filter mesh disc, bong burner mesh, Arabic hookah filter, or faucet water impurity filter. It is mainly u...

View Detail -

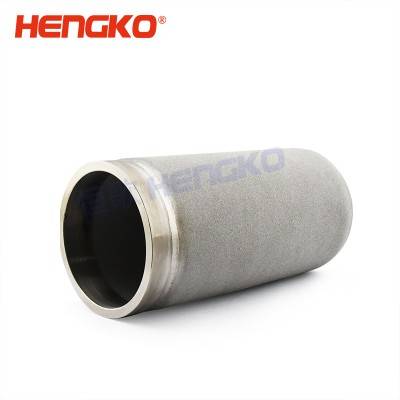

Wholesale Wire Mesh Filter Stainless Steel 10 Micron Sintered Tube For Pharmaceutical M...

Stainless steel filters are ideal for use in demanding engineering specifications that require filtration in adverse environmental conditions, such as jet en...

View Detail -

20 Micron 316 Stainless Steel Wire Mesh Filter Cartridge Inner Core 32mm Length M4 Thread

Wire mesh filter is wire mesh that is stretched by use of metal threads, with fine openings between the different metal threads. When polluted water is pump...

View Detail -

Reverse Osmosis Stainless Steel Filter Water Filter Purifier Filtration System SS 316 M...

Reverse Osmosis Stainless Steel Filter Water Filter Purifier Filtration System SS 316 Mesh Cartridge Filter Product Description Everyone is looking for n...

View Detail -

RHTX Series mesh-protected weather-proof humidity sensor probe housing

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

4-20mA Infrared CH4 CO2 gas sensor ( carbon dioxide sensor ) detector aluminum alloy ho...

Stainless steel housing with tamperproof protection. For use with separately certified, industry-standard junction boxes or OEM gas detector enclosures. ...

View Detail -

Sintered stainless steel/wire mesh explosion-proof filter housing for carbon monoxide l...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Stainless Steel Metal Mesh Filter last Chance Filters for the Printing Industry

HENGKO manufactures metal mesh filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics an...

View Detail -

Sintered Metal Stainless Steel Porous Mesh Filters for in High Pressures Enviroments Ma...

Hengko’s food-grade textile filters are primarily manufactured in the form of cups, threaded cups, discs, and extended area packs. These filters are primaril...

View Detail -

Gas Diffusion Layers Sheet for MEAs, stainless steel porous metal sintered / wire mesh ...

HENGKO stainless steel filter plates are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been ...

View Detail -

Precious Metal Catalyst Filters – Stainless steel multi-layer mesh filter candle

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

High quality y strainer filter, sintered filter mesh for gas filtration

y strainer filter mesh is used in piping to prevent debris from flowing through pipes. Fluid passes through the sintered filter, which filters out foreign ma...

View Detail -

0.2um to 90 micron 5 – 100mm height powder or wire mesh porous sintered metal sta...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

5 10 25 micorns porous 316L stainless steel powder/wire mesh sintered metal refillable ...

HENGKO stainless steel filter tubes are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been w...

View Detail -

Multi-layer sintered stainless steel mesh plate fluidized bed equipment Distributor bot...

Stainless steel mesh plate for fluid bed Control of gas distribution, powdered material transmission, and fluidization operation has been widely used in indu...

View Detail -

small sintered stainless steel mesh disc filter for use on inkjet Printers

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration coolin...

View Detail -

Catalyst Filtration with Leaf Filters Sintered Metal Mesh Filter Disc for the Recovery ...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

customized stainless steel 316 316L wire mesh tube / cartidge filter used for medical p...

HENGKO sintered wire mesh tube/cartridge filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particl...

View Detail -

Customized medical 304 316 316L stainless steel filter mesh cartridges from HENGKO

Made of a multi-layer sintered 316 or 304 stainless steel strainer, it has the properties of heat resistance, pressure resistance, and corrosion resistance.T...

View Detail

HENGKO is recognized as one of China's premier OEM suppliers of sintered wire mesh.

With a strong commitment to quality, customizability, and customer satisfaction, HENGKO has set a

high standard in the sintered wire mesh industry.

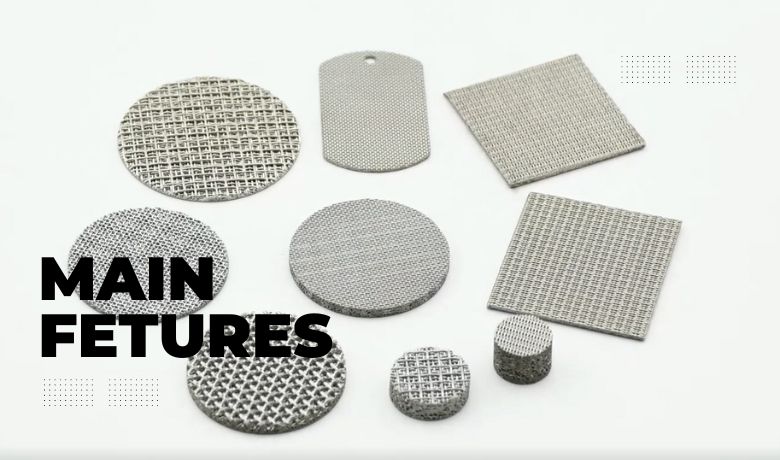

Sinter Wire Mesh Main Filter Features

Sintered wire mesh is created by sintering, heating, and pressing small wire mesh pieces together to create a larger, more durable mesh. This type of wire mesh has several unique features that suit certain applications well.

1.) One of the most notable features of sintered wire mesh is its high strength and durability. Because the small wire mesh pieces are heated and pressed together, the resulting sintered wire mesh is very strong and resistant to damage. It makes it ideal for use in applications where the mesh will be subject to high levels of wear and tear, such as filtration systems and support structures.

2.) Another important feature of sintered wire mesh is its ability to retain its shape and structure under high pressure. It is ideal for use in applications where the mesh will be subject to high-stress levels, such as filtration systems and support structures. Because sintered wire mesh can maintain its shape and structure under high pressure, it can also support heavy loads without deforming or breaking.

3.) Sintered wire mesh is also notable for its corrosion resistance. The sintering process creates a strong bond between the individual wire mesh pieces, which helps to prevent the formation of corrosion-causing gaps or spaces. It makes sintered wire mesh an ideal choice for applications that expose the mesh to corrosive environments, such as chemical processing plants and marine environments.

Overall, sintered wire mesh is a strong, durable, and corrosion-resistant material that is well-suited to many applications. Its unique features make it ideal for high-pressure, high-wear, and corrosive environments.

The Versatile Applications of Sintered Wire Mesh Filters

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration cooling under extremity high temperature, control airflow distribution, enhancement of heat and mass transfer, noise reduction, current limitation, and wildly used in aerospace, petrochemical industry, pharmaceutical industry, environmental protection industry.

Specifications of Sintered Wire Mesh

Material:

Standard material 304), 316 / 316L, Alloy Steel Hastelloy, Monel, and Inconel.

Standard and Popular Size:

500 × 1000 mm, 600 × 1200 mm, 1000 × 1000 mm,

1200 × 1200 mm, 300 × 1500 mm.

Fabrication:

Easily Formed, Sheared, Welded, and Punched.

What Types of Sinter Mesh filters do We Supply:

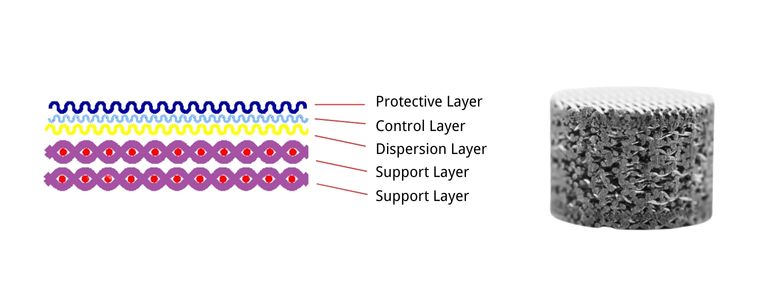

1. Standard combination of 5-layer sintered wire mesh.

2. Sintered together by many layers of plain-woven square mesh.

3. Sintered Woven Wire Mesh by Multi-Layers Stainless Steel Wire

4. Sintered by perforated plate and multi-layer stainless steel wire mesh.

5. OEM any Sharp for your projects. Our sintered mesh panels can be formed

into filter elements such as filter discs, cartridges, cones, cylinders, and tubes.

Some Advantages of Sintered Wire Mesh

1. High strength and durability since high-temperature sintering.

2. Anti-corrosion and heat resistance up to 480 °C.

3. Steady filter rating from the 1micron to 100 microns.

4. Filter mesh cannot easily deform because of two protective layers.

5. Can be used for uniform filtration in high-pressure or high-viscosity environments.

6. Suits for cutting, bending, punching, stretching, and welding.

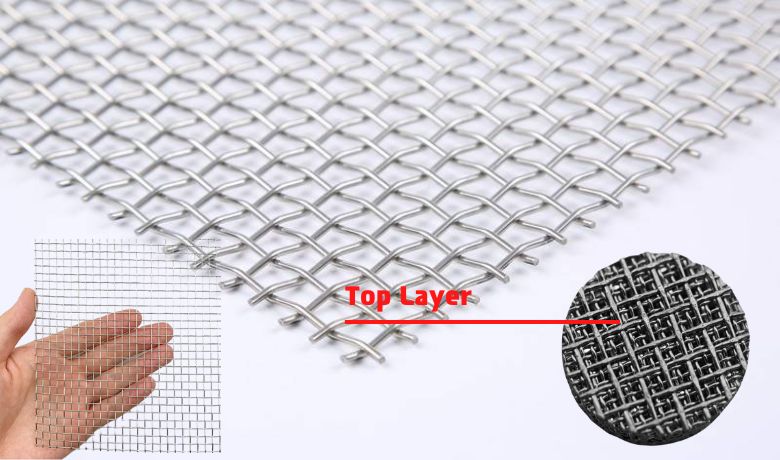

Woven Wire Mesh VS Sintered Mesh

Both woven wire mesh and sintered wire mesh play an important role in filtration among various applications like oil & gas filtration. It is known that sintered wire mesh is a kind of diffusion-bonded woven wire mesh or that sintered wire mesh is woven wire mesh that experienced a heat-treating process, which will improve many original properties. Our company has rich experience in manufacturing those meshes and will produce professional advice to help you select the suitable filter mesh. To learn better-woven wire mesh & sintered mesh, let's start with the concept of woven wire mesh.

What is Woven Wire Mesh?

Woven wire mesh is typically woven with wires running in two vertical directions - warp & shute, and is manufactured in rolls. Standard mesh roll size would be 36" or 48" wide × 100 ft long. The wires running the full length are called "warp" wires, while those running across the width are called "weft," "fill," or "shute" wires. See the Fig-1; you will find the four frequently-used weave styles. Sometimes depending on our customers' special requirements, the bespoke type will be available. Commonly, the twilled dutch weave is for the finest meshes, while plain & dutch weaves are for relatively coarse mesh.

What Are Sintered Mesh Laminates?

Fine Layer Woven Wire filter mesh provides micron-rated pore size, but it is too thin to be damaged. The best solution is to laminate the fine mesh to a coarser supportive layer to provide strength and thickness. The standard sintered wire mesh laminates are 5-layer sintered wire mesh or 6-layer, extensively used in filtration.

Video Show

FAQ

1. What is Sintered Wire Mesh and what are its uses?

Sintered Wire Mesh is a robust, multi-layered mesh made from stainless steel that has been thermally bonded, or sintered, under high pressure to create a unified piece with tremendous strength and filtration properties. This material's durability, along with its precise filtration capacity, renders it indispensable in numerous sectors such as petrochemical, pharmaceutical, food and beverage, aerospace, and environmental protection. Whether purifying air, sieving particles from liquids, or regulating oil flow, Sintered Wire Mesh exhibits outstanding performance.

2. How does the customizing process for Sintered Wire Mesh work at HENGKO?

At HENGKO, we operate with an unswerving dedication to meeting our client's unique needs. This commitment is reflected in our custom-made Sintered Wire Mesh service. We begin by understanding our client's requirements in terms of design, size, and pore size.

This collaborative dialogue forms the bedrock of our customization process. Post consultation, our proficient team of engineers utilizes cutting-edge technology to fabricate Sintered Wire Mesh pieces that precisely conform to the outlined specifications. The result is a tailor-made solution that ensures optimal flow control and meets the stringent standards of your projects.

3. How does Sintered Wire Mesh contribute to filtration efficiency?

Sintered Wire Mesh is renowned for its exceptional filtration capabilities. Its multi-layered construction results in a composite material that boasts enhanced mechanical properties and precise filtration characteristics. The choice of pore size plays a crucial role in determining the mesh's filtration capabilities.

Depending on the application, pore sizes can be customized to allow fine particles to pass while effectively trapping larger ones, thus maximizing filtration efficiency. Furthermore, the robust nature of Sintered Wire Mesh ensures consistent performance and longevity, reducing maintenance costs and boosting overall process efficiency.

4. What sets HENGKO's Sintered Wire Mesh products apart?

HENGKO's Sintered Wire Mesh products stand out due to our unyielding commitment to quality and customer satisfaction. Our decade-long presence in the industry has enabled us to refine our manufacturing processes, ensuring each product we deliver lives up to our high standards.

Additionally, our dedication to offering bespoke solutions caters to a vast range of requirements, thereby solidifying our standing as a flexible and customer-centric provider. We firmly believe in our products' ability to enhance the success of your filtration projects, providing unparalleled precision and efficiency.

5. What materials are used in the production of Sintered Wire Mesh at HENGKO?

Predominantly, stainless steel forms the backbone of our Sintered Wire Mesh owing to its remarkable strength, corrosion resistance, and thermal stability. However, our pursuit of excellence and customer satisfaction compels us to venture beyond the conventional.

Thus, we offer meshes made from a variety of materials such as Monel, Inconel, Hastelloy, and more. This diversity ensures that we cater to a wide array of application scenarios, each demanding a unique set of material properties.

6. How does the sintering process affect the properties of Wire Mesh?

Sintering is a heat treatment process that enhances the strength and rigidity of the wire mesh without compromising its filtration characteristics. By applying high heat and pressure, the individual wires are bonded, creating a unified structure with superior mechanical integrity.

This process not only amplifies the mesh's resistance to physical stresses but also its resistance to temperature and corrosion. The result is a highly durable product that can sustain rigorous operational conditions.

7. Can Sintered Wire Mesh be cleaned and reused?

One of the key advantages of our Sintered Wire Mesh products is their reusable nature. These robust filters can withstand multiple cleaning cycles, be it by backwashing, ultrasonic methods, or even chemicals, depending on the contamination.

This feature significantly reduces the total cost of ownership by prolonging the filter's operational lifespan and minimizing the need for replacements.

8. How does HENGKO ensure the quality of its Sintered Wire Mesh products?

Quality assurance is ingrained in HENGKO's manufacturing ethos. Our products undergo stringent quality checks at every stage of production, from raw material selection to final product testing. Our team leverages sophisticated inspection technologies to ensure that every Sintered Wire Mesh piece meets the highest standards of quality, durability, and performance.

It is this relentless pursuit of excellence that enables us to deliver products that exceed customer expectations and uphold our reputation as a leading provider in the industry.

9. Why is stainless steel a popular choice for sintered wire mesh?

Till Now Stainless steel is a popular choice for sintered wire mesh for several reasons in some special industrial :

1. Corrosion resistance:

Stainless steel is known for its excellent resistance to corrosion, especially when compared to other metals like carbon steel.

This makes it ideal for applications where the mesh will be exposed to harsh chemicals, salt water, or other corrosive environments.

2. High strength and durability:

Sintering creates a strong bond between the wires in the mesh, making it highly resistant to tearing, breaking, and deformation.

This is especially important for applications where the mesh will be under pressure or subjected to repeated use.

3. Heat resistance:

Stainless steel can withstand high temperatures without losing its strength or integrity.

This makes it suitable for applications involving hot fluids or gases.

4. Easy to clean and maintain:

The smooth surface of stainless steel makes it easy to clean and remove contaminants.

This is crucial for applications where hygiene and purity are important.

5. Versatility:

Stainless steel sintered wire mesh is available in a wide range of grades, pore sizes, and thicknesses,

making it suitable for a variety of applications.

In addition to these benefits, stainless steel is also relatively affordable and readily available, making it a practical choice for many manufacturers.

Here are some other advantages of using stainless steel sintered wire mesh:

1. It is non-toxic and safe for use in food and beverage applications.

2. It is recyclable, making it an environmentally friendly choice.

3. It has a long lifespan, which can help to reduce maintenance costs.

Overall, stainless steel is a popular choice for sintered wire mesh due to its combination of excellent corrosion resistance,

high strength, heat resistance, ease of cleaning, versatility, and affordability.

10. Why are there 5 layers instead of 3 or 7? What are the benefits of having 5 specifically?

There are several reasons why a 5-layer sintered wire mesh might be chosen over 3 or 7 layers:

1.) Balancing performance and cost:

3 layers may not offer sufficient filtration efficiency or structural integrity for demanding applications.

7 layers can be overkill, increasing cost and pressure drop without necessarily delivering significant benefits.

5 layers strike a balance between cost, performance, and desired features.

2.) Achieving specific filtration characteristics:

Each layer can have a different pore size or wire diameter, allowing for multi-stage filtration with varying degrees of coarseness.

The layers can be strategically arranged to achieve specific flow patterns, optimize backwashing efficiency, or address specific particle capture needs.

5 layers provide enough flexibility to create a customized "recipe" for targeted filtration performance.

3.) Enhancing strength and durability:

Each layer acts as a reinforcement for the others, creating a more robust and tear-resistant structure compared to fewer layers.

The layered configuration can distribute pressure and stress more evenly, making it suitable for high-pressure applications.

5 layers might be optimal for achieving a desired level of strength without adding unnecessary bulk or weight of a 7-layer mesh.

4.) Addressing specific application challenges:

Some applications require a combination of high flow rate and fine filtration. 5 layers can offer a sweet spot, allowing sufficient flow without compromising on particle capture.

High-temperature or corrosive environments might demand additional layers for enhanced resistance while keeping the overall thickness manageable.

The specific number of layers may be dictated by the desired surface area, pressure drop requirements, or integration with existing equipment.

Ultimately, the choice between 3, 5, or 7 layers depends on the specific needs of the application. Factors like particle size, flow rate, pressure, budget, and desired level of performance will all play a role in determining the optimal number of layers.

Choosing a 5-layer mesh doesn't always mean it's the "best" option. However, it represents a well-rounded solution that often delivers a balance of performance, cost-effectiveness, and flexibility, making it a popular choice for various applications.

11. How can I ensure I'm getting high-quality sintered mesh from a reputable Chinese supplier?

For this question, before you souring from China, Ensuring high-quality sintered mesh from a Chinese supplier requires a multi-pronged approach as following :

1. Supplier research and due diligence:

Check company credentials: Look for established manufacturers with a proven track record in the industry. Verify their registration, certifications (e.g., ISO 9001), and export licenses.

Customer reviews and testimonials: Search online platforms and industry forums for feedback on the supplier's quality, reliability, and customer service.

Audit reports and independent testing: Request factory audits and independent testing reports for their sintered mesh products. This can reveal adherence to quality standards and performance specifications.

Visit the factory (optional): If possible, schedule a visit to the factory to observe their production process, equipment, and quality control measures firsthand.

2. Product specifications and clarity:

Detailed product information: Request precise data sheets, including material grades, pore size, wire diameter, filtration efficiency, pressure drop, and surface finish.

Customizations and tolerances: Clearly define your specific requirements and acceptable tolerances for the mesh, ensuring the supplier understands your needs.

Sample testing: Ask for pre-production samples to evaluate the mesh's quality, performance, and consistency before committing to a large order.

3. Communication and contract terms:

Clear communication: Maintain open communication with the supplier, expressing your expectations and concerns promptly.

Contractual safeguards: Ensure the contract includes clear terms on quality standards, inspection procedures, warranties, and dispute resolution mechanisms.

Payment terms: Consider using secure payment methods with escrow or staged payments tied to production milestones and quality checks.

4. Post-delivery inspection and Inspect the delivered goods:

Thoroughly inspect the mesh upon arrival, comparing it to the agreed-upon specifications and using any pre-determined testing methods.

Maintain communication: Keep the supplier informed of any performance issues or concerns encountered with the mesh.

5. Long-term relationship building:

Foster a long-term partnership with reliable suppliers who demonstrate commitment to quality and customer satisfaction.

By following these steps, you can significantly increase your chances of sourcing high-quality sintered mesh from a reputable Chinese supplier.

Remember, due diligence, clear communication, and contractual protection are key to securing the best possible outcome for your project.

Have Any Questions for the Sintered Wire Mesh, Please don't hesitate to

Contact us by email ka@hengko.com or send as follow form, we care your

filtration projects and we will send back within 24-Hours.