-

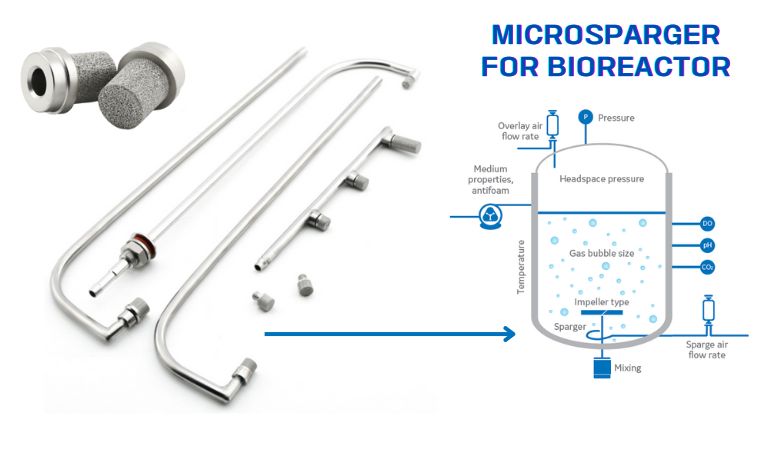

Stainless Steel 316 Micro Spargers and Filter in Bioreactors and Fermentors

Product Describe The function of the bioreactor is to provide a suitable environment in which an organism can efficiently produce a target product. * Cell b...

View Detail -

Stainless Steel Air Fine Bubble Oxygen Diffuser Stones for Microalgae Photobioreactor a...

(Photobioreactor) systems are devices that can contain and grow algae, cyanobacteria, and other photosynthetic organisms under heterotrophic and mixotrophic ...

View Detail -

HENGKO® Diffusion stone for wastewaterfor microalgae farming

Revolutionize Mariculture Wastewater Treatment with our Cutting-Edge Microalgae Technology! Our groundbreaking project focuses on the treatment and comprehen...

View Detail -

Single Use Bioreactor diffuser sparger for cell culture

In the initial stage of upstream processing in bioprocessing, fermentation is commonly used. Fermentation is defined as the chemical changes caused by microo...

View Detail -

multi – bioreactor sparger for the fermenter sartorius

The Stainless Steel Fermenter|Bioreactor for Your Laboratory A bioreactor is a type of fermentation vessel that is used for the production of various chemica...

View Detail -

Sintered Microsparger in Bioreactor System for Green chemistry industry

The importance of aeration and gas dispersion to achieve good oxygen mass transfer cannot be understated. This is at the heart of the ability of mic...

View Detail -

Sintered Micro Porous Sparger in Benchtop for Bioreactors and Laboratory Fermenter

Every bioreactor sparging system is designed for the introduction of oxygen to feed cell cultures. Meanwhile, the system must remove carbon dioxide to preven...

View Detail -

Quick Change Sparger System for Bioreactors and Fermentors Air Sparger Accessories- Mic...

Stainless steel sparger is to supply enough oxygen to the microbes in submerge culture technique for proper metabolism. Each fermentation process requires a ...

View Detail -

Bioprocess Lab Spin Sintered SS Filter screen Fermenter Bioreactor System

Enhance Your Cell Culture Processes with HENGKO's Stainless Steel Spin Filter! Experience the power of our 4-layer square mesh spin filter, expertly ...

View Detail -

Sintered Sparger Tube with Porous Metal Stainless Steel Tank and In-line Spargers Used ...

Introducing the exceptional HENGKO sintered spargers, the ultimate solution to introducing gases into liquids. This innovative product utilizes thousands of...

View Detail -

Sintered Sparger Stainless Steel Material Quick Change for Bioreactor Systems

In bioreactor systems, optimal mass transfer of gases like oxygen or carbon dioxide is difficult to accomplish. Oxygen, in particular, is poorly soluble in w...

View Detail -

Biotech Removable Porous Frit Micro Sparger for Mini Bioreactor System and Fermentors

Stainless steel sparger used as a cell retention device. The device consists of a metal tube and a sintered metal filter with a pore size of 0.5 – 40 µm. The...

View Detail -

Stainless Steel Sparger 2 Micron Stainless Steel Cabonation Diffusion Stone for Bacteri...

Introducing HENGKO's innovative sintered spargers - the ultimate solution for efficient gas-liquid contact in a variety of industries. Our spargers use thou...

View Detail -

Micro Spargers Increase Gas Transfer and Improve Upstream Reactor Yields for Bioreactors

Introducing HENGKO sintered spargers - the ultimate solution to introduce gases into liquids with ease! Our innovative spargers feature thousands of tiny po...

View Detail -

Micro spargers bubble air aeration stone for bioreactor assembly

Micro spargers from HENGKO reduce bubble size and increase gas transfer to reduce gas consumption and improve upstream reactor yields. HENGKO spargers can in...

View Detail

Typical Sparge Tube Design Idea

Smaller bioreactors can efficiently distribute oxygen and remove carbon dioxide without nebulizers. However, these measures do not apply to larger bioreactors, as the lower surface area to volume ratio leads to carbon dioxide accumulation and prevents oxygen penetration. Therefore, nebulizers are necessary for the introduction of oxygen and the removal of carbon dioxide.

Systems with micro and large nebulizers are often useful because they can meet different process needs. For example, large nebulizers produce larger bubbles that effectively remove dissolved CO 2 from the solution, but large bubbles require vigorous agitation to break them down and release oxygen.

While this may work well for cold-tolerant cell lines, stirring can damage more delicate mammalian cells. In these cases, a lower-powered macro-distributor can be used first to remove CO 2 and then a micro-distributor in series to produce smaller bubbles that deliver oxygen more efficiently.

Sintered Porous Metal Sparger Makes

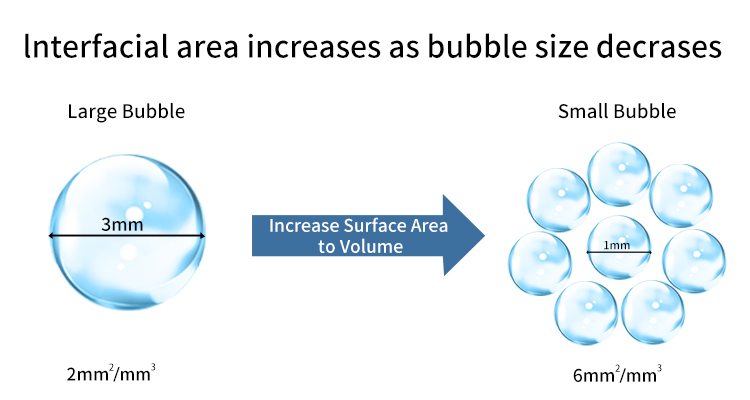

Interfacial Area Increases But Bubble Size Decreases

The Challenge: Bubble Characteristics Determine O2 Transport and CO 2 Vapor Extraction Rates

Bubble formation and size significantly affect how oxygen is dispersed throughout the bioreactor. Bubble characteristics are significantly influenced by pore size and distribution, distributor material, flow rate, liquid and gas properties, and pressure. For example, micro sprayers produce smaller, spherical bubbles, while larger sprayers produce slightly larger and less uniformly shaped bubbles.

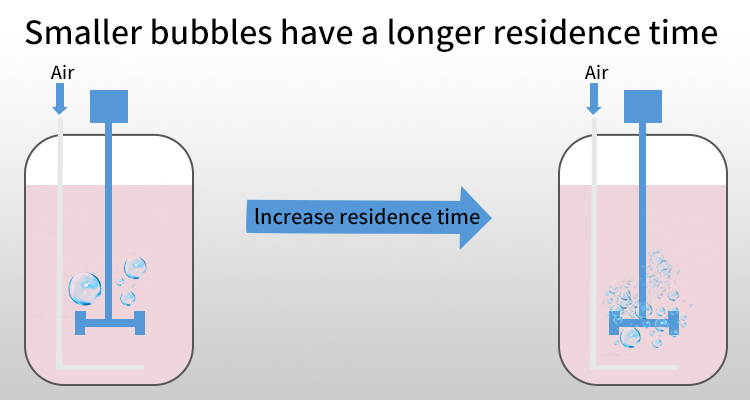

Micro spargers produce micron-sized and spherical bubbles, and surface tension is the dominant force as they pass through the bioreactor. They, therefore, have a long residence time in the reactor, which improves oxygen transfer, but is not suitable for removing carbon dioxide from the culture.

Large nebulizers produce bubbles with an average diameter of 1-4 mm, where surface tension and buoyancy in the broth combine to influence their shape and movement. These bubbles have a shorter residence time but are less likely to dissolve than smaller bubbles. However, micro spargers may also produce larger asymmetric bubbles, with inertial forces governing their behavior. These bubbles can easily burst without dissolving or stripping CO2.

The shape and size of the bubbles determine the amount of shear stress the cell will experience, the effectiveness of stripping CO 2 from the system, and the rate of total oxygen transfer to the cell. Therefore, it is important to optimize the bioreactor nebulizer to ensure that the oxygen bubbles are uniform in size and distribution and do not damage the cells.

Solution: Use Strict Production Quality Control of the HENGKO Bioreactor Sparger

HENGKO has more than twenty years of experience developing and producing sintered sparger. Our stainless steel sparger are the result of dozens of engineers who have often improved the production method to produce this high-quality product with uniform pores and, thus, uniform bubble size released into the bioreactor. Our porous spargers are recommended for use with low-flow mass flow controllers.

How to use: The low-flow mass flow controller slowly introduces oxygen into the porous sparger. The spargers does not immediately release gas. Instead, the pressure gradually increases until a critical point is reached, at which point the bubbles are gently released into the bioreactor.

Using this sparging method, the oxygen mass flow rate can be adjusted to control the release rate of the bubbles into the bioreactor. The holes in the sparger are small enough that bubbles will form predictably. Therefore, this bioreactor sparging technology is scalable across vessel sizes, with an oxygen transfer rate proportional to the gas flow rate.

Questions About Bioreactor Sparger

1. What is a Sparger in Bioreactor?

In short, a sparger is a device used in a bioreactor to introduce gases, such as oxygen or air, into the liquid medium. The main function of a sparger is to provide oxygen to the microorganisms in the bioreactor, which is necessary for their growth and metabolism.

The Sparger in a bioreactor is used to add gases such as oxygen, air, or other gases required for the growth and metabolism of the microorganisms. The oxygen is supplied to the microorganisms through the Sparger, which helps to maintain the dissolved oxygen levels in the liquid medium. The dissolved oxygen levels are an important parameter to monitor and control during the bioprocess as it directly affects the growth and metabolism of the microorganisms.

The Sparger is designed to introduce the gas into the liquid medium in a controlled manner, such as through porous materials or tubes. The Sparger can be located at the bottom or the top of the bioreactor, depending on the design of the bioreactor and the type of microorganisms used. The Sparger can be adjusted to provide the desired oxygen transfer rate and to maintain the appropriate dissolved oxygen level in the medium.

The Sparger also plays an important role in maintaining the mass transfer rate, which is the rate at which the oxygen is transferred from the gas phase to the liquid phase. The mass transfer rate can be affected by factors such as the size and shape of the bioreactor, the type and concentration of microorganisms, and the temperature and pH of the medium. The Sparger can be used to control these factors and to optimize the mass transfer rate, which is crucial for the success of the bioprocess.

In summary, the main function of a sparger in a bioreactor is to provide oxygen to the microorganisms in the liquid medium, which is necessary for their growth and metabolism, and to maintain the appropriate dissolved oxygen levels and mass transfer rate, which are essential for the success of the bioprocess.

What is Meant by Sparger?

A sparger is a device that is used to introduce gas into a liquid. It is commonly used in bioreactors, which are specialized vessels used to cultivate microorganisms or cells under controlled conditions.

What is the Function of Sparger?

The function of the sparger is to provide oxygen or another gas to the bioreactor in order to support the growth and metabolism of the cells or microorganisms.

What is the Use of Sparger in Bioreactor Explain Its Types?

There are several types of spargers that can be used in a bioreactor. These include bubble spargers, which create a continuous stream of bubbles in the liquid, and spray spargers, which disperse the gas as a fine mist. Other types of spargers include porous spargers and hollow-fiber spargers.

Where is the Sparger Located in Bioreactor?

The sparger is typically located at the bottom of the bioreactor, where it can effectively mix the gas with the liquid. In large-scale fermentation processes, bubble spargers are often used as they are relatively simple and inexpensive to operate.

Which Type of Sparger is Mostly Used in Large Scale Fermentation?

In large-scale fermentation processes, bubble spargers are often used as they are relatively simple and inexpensive to operate. A bubble sparger consists of a tube or pipe with small holes or slots through which the gas is introduced into the liquid. The gas flows through the holes or slots and forms a continuous stream of bubbles in the liquid. Bubble spargers are effective at providing a large volume of gas to the bioreactor and can be easily adjusted to control the flow rate of the gas. They are also relatively easy to clean and maintain. However, bubble spargers can create relatively large bubbles which may not be as effective at providing a high surface area for the cells or microorganisms to come into contact with the gas. In some cases, a spray sparger or other type of sparger may be more appropriate for a particular fermentation process.

What Do you Need to Know About the Sparger System?

There are several things that you should consider when using a sparger system in a bioreactor. These include:

-

Calibration: It is important to properly calibrate the flow rate of the gas being introduced into the bioreactor. This will ensure that the correct amount of gas is being supplied to the cells or microorganisms and that the oxygen concentration in the bioreactor is within the desired range.

-

Oxygen concentration: The oxygen concentration in the bioreactor should be monitored regularly to ensure that it is within the desired range for the cells or microorganisms being cultivated. If the oxygen concentration is too high or too low, it can affect the growth and metabolism of the cells or microorganisms.

-

Contamination prevention: It is important to ensure that the sparger and the surrounding area are properly cleaned and maintained to prevent contamination of the bioreactor. This may include regularly replacing gas filters and cleaning the sparger and the surrounding areas with appropriate disinfectants.

-

Gas flow rate: The flow rate of the gas should be adjusted as needed to maintain the desired oxygen concentration in the bioreactor. The flow rate may need to be increased or decreased based on the oxygen demand of the cells or microorganisms and the rate of gas consumption.

-

Maintenance: Regular maintenance of the sparger system is important to ensure that it is operating properly and efficiently. This may include checking for leaks, replacing worn or damaged parts, and cleaning the sparger and surrounding areas as needed.

2. Main Function of Sparger in Bioreactor?

The main function of a sparger in a bioreactor is to introduce gases, such as oxygen or air, into the liquid medium. It is necessary for the growth and metabolism of the microorganisms in the bioreactor, as they require oxygen for respiration. The Sparger helps to provide the microorganisms with the necessary oxygen and maintain a suitable oxygen level in the bioreactor to support their growth and metabolism, which is essential for the success of the bioprocess.

A: Introducing gases: The main function of a sparger in a bioreactor is to introduce gases, such as oxygen or air, into the liquid medium. It helps to provide the microorganisms with the necessary oxygen for growth and metabolism.

B: Maintaining dissolved oxygen levels: The Sparger helps to maintain the dissolved oxygen levels in the liquid medium. These levels are an important parameter to monitor and control during the bioprocess as they directly affect the growth and metabolism of the microorganisms.

C: Controlling gas transfer rate: The Sparger is designed to introduce the gas into the liquid medium in a controlled manner. The Sparger can be adjusted to provide the desired oxygen transfer rate and to maintain the appropriate dissolved oxygen level in the medium.

D: Maintaining mass transfer rate: The Sparger also plays an important role in maintaining the mass transfer rate, which is the rate at which the oxygen is transferred from the gas phase to the liquid phase.

E: Optimizing bioprocess: The Sparger can be used to control factors such as the size and shape of the bioreactor, the type, and concentration of microorganisms, and the temperature and pH of the medium, to optimize the bioprocess.

F: Providing Mixing: Spargers also help create a homogenous mixture of the liquid and the gas by providing mixing action. It helps in providing the microorganisms with a uniform environment.

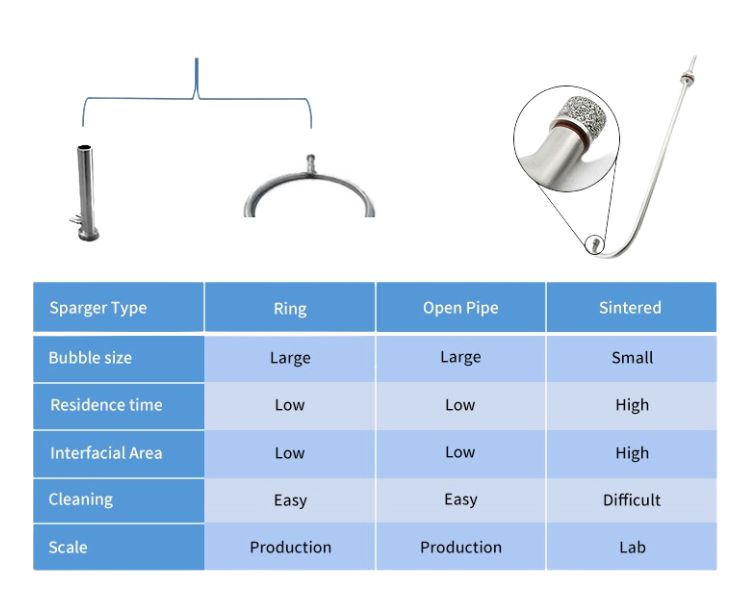

3. Types of Sparger in bioreactor?

Several types of spargers include porous stone spargers made of a porous material such as ceramic or sintered metal and bubble column spargers, which use a series of tubes or nozzles to introduce the gas into the liquid.

Several types of spargers can be used in a bioreactor, including:

1. Porous stone spargers: These are made of a porous material such as ceramic or sintered metal and are placed at the bottom of the bioreactor. They provide a large surface area for gas transfer and are commonly used in small-scale bioreactors.

2. Bubble column spargers: These use a series of tubes or nozzles to introduce the gas into the liquid. They can be placed at the bottom or the top of the bioreactor and are commonly used in larger-scale bioreactors.

3. Ring sparger: These are placed at the bottom of the bioreactor and utilize a ring-shaped structure to produce bubbles and provide oxygen transfer.

4. Micro-bubble Sparger: These are designed to produce small bubbles that provide high oxygen transfer efficiency and are widely used in large-scale, high-density bioreactors.

5. Jet sparger: These use a set of nozzles to introduce the gas into the liquid. They can be placed at the bottom or the top of the bioreactor and are commonly used in high-shear bioreactors.

6. Paddlewheel sparger: This type of Sparger uses a rotating paddle wheel to create bubbles and provide oxygen transfer. It is commonly used in fermentation processes.

These are some of the commonly used sparger types in bioreactors, and the choice of Sparger depends on the size, type, and design of the bioreactor and the specific bioprocess being used.

4. How to Set Sparging Levels in Bioreactor?

The sparging level in a bioreactor is typically set based on the oxygen demand of the microorganisms, the rate of gas transfer, and the gas flow rate. Factors that can affect the sparging level include the size and shape of the bioreactor, the type and concentration of microorganisms, and the temperature and pH of the medium.

5. Role of Sparger in Bioreactor?

The role of a sparger in a bioreactor is to introduce gases, such as oxygen or air, into the liquid medium to meet the oxygen demand of the microorganisms. It is essential for the growth and metabolism of the microorganisms and, ultimately, for the bioprocess's success.

The Sparger helps to provide the microorganisms with the necessary oxygen for growth and metabolism. It helps to maintain the dissolved oxygen levels in the liquid medium, which are important parameters to monitor and control during the bioprocess as they directly affect the growth and metabolism of the microorganisms.

The Sparger is designed to introduce the gas into the liquid medium in a controlled manner, such as through porous materials or tubes. The Sparger can be located at the bottom or the top of the bioreactor, depending on the design of the bioreactor and the type of microorganisms used. The Sparger can be adjusted to provide the desired oxygen transfer rate and to maintain the appropriate dissolved oxygen level in the medium.

The Sparger also plays an important role in maintaining the mass transfer rate, which is the rate at which the oxygen is transferred from the gas phase to the liquid phase. The mass transfer rate can be affected by factors such as the size and shape of the bioreactor, the type and concentration of microorganisms, and the temperature and pH of the medium. The Sparger can be used to control these factors and to optimize the mass transfer rate, which is crucial for the success of the bioprocess.

Sparger also helps create a homogenous mixture of the liquid and the gas by providing mixing action. It helps in providing the microorganisms with a uniform environment.

In summary, the role of a sparger in a bioreactor is to provide oxygen to the microorganisms in the liquid medium, which is necessary for their growth and metabolism, and to maintain the appropriate dissolved oxygen levels and mass transfer rate, which are essential for the success of the bioprocess. It also helps create a homogenous mixture and provides mixing action to the liquid medium.

What kind of Bioreactor Sparger do you interested to use or Customize ?

you are welcome to contact us by emial ka@hengko.com , or can send inquiry at the

bottom contact form , we will send back to you asap within 24-Hours.