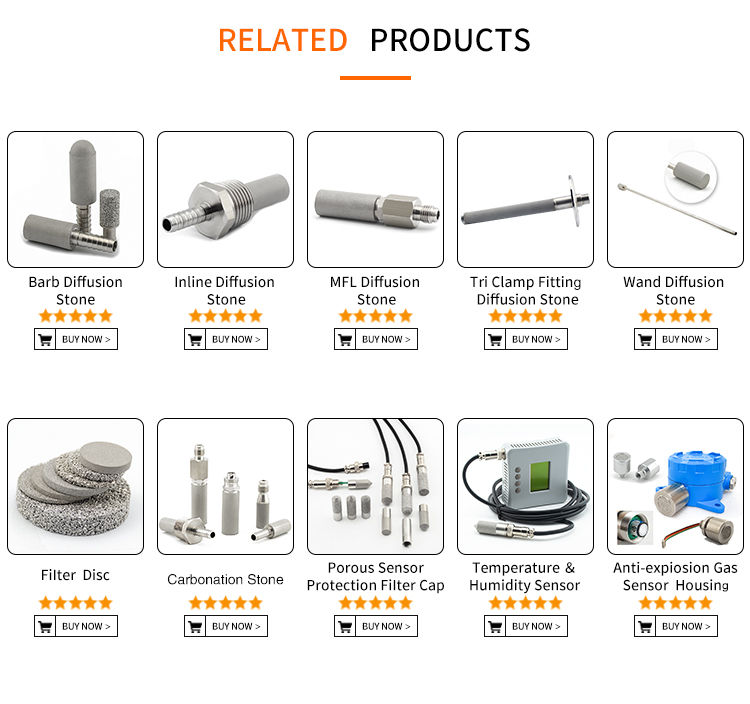

Sintered Sparger Tube with Porous Metal Stainless Steel Tank and In-line Spargers Used in Bioreactors

Introducing the exceptional HENGKO sintered spargers, the ultimate solution to introducing gases into liquids. This innovative product utilizes thousands of tiny pores to create bubbles that are far smaller and more numerous than with drilled pipe or other sparging techniques. With HENGKO sintered spargers, you can enjoy a greater gas-liquid contact area, which means you can reduce the time and volume required to dissolve gas into a liquid.

Designed to work with a variety of different gases, including nitrogen, air, and CO2 spargers, HENGKO sintered spargers are tailored to meet your specific needs. Whether you need to add a particular gas to a liquid or require unique specifications for your sparger, our team will work with you to create a customized solution that meets your requirements.

One of the key benefits of HENGKO sintered spargers is their ability to create bubbles that are much smaller and finer than those produced by other sparging methods. This allows for a more significant gas-liquid contact area and reduces the amount of time and volume required to dissolve gas into a liquid significantly.

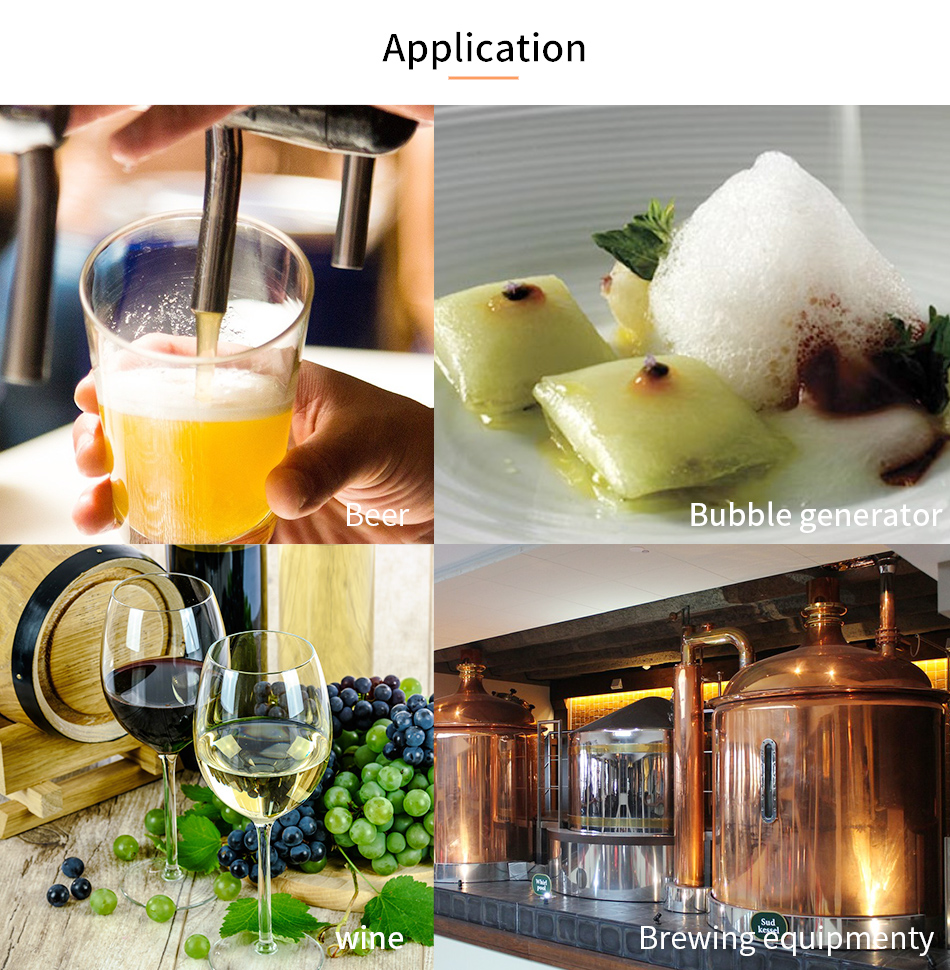

But that's not all. HENGKO sintered spargers are also incredibly versatile and can be used in a wide range of applications. Whether you're looking to improve the efficiency of your industrial processes, add oxygen to aquariums, or enhance the quality of your fermentation or aeration processes, our spargers can do the job.

Not only are our sintered spargers effective, but they are also incredibly durable and long-lasting, thanks to the use of high-quality materials in their construction. They are resistant to high-temperature, high-pressure, and corrosive environments, making them an ideal choice for use in tough industrial applications.

In conclusion, if you're looking for a high-quality sparging solution that can provide you with a greater gas-liquid contact area, reduce the time and volume needed to dissolve gas into a liquid, and is built to last, then HENGKO sintered spargers are the perfect solution for you. Contact us today to learn more about our products and let us help you find the perfect sparging solution for your needs.

Sintered sparger tube with porous metal stainless steel tank and in-line spargers used in bioreactors