-

Biopharmaceutical purification and filtration porous filter plate 10um 20um 50um

A porous filter plate is a new type of high-efficiency porous filter material made of metal stainless steel powder through powder sieving, moulding, sinterin...

View Detail -

wide mouth jar mason jar with stainless steel sintered filter disc for high temperature...

Small changes, big benefits! We store bentonite clay inside the jar and bake it in a vacuum oven to remove moisture. Even with the lid on the clay gets out o...

View Detail -

NW25 and KF25 Flange-Centering O-Ring with Fine Filter

ISO-KF and NW Sintered Metal Filter Centering Ring NW-16、NW-25、NW-40、NW-50 Supplier With fine filter (sintered porous metal filter or choose wire mesh f...

View Detail -

NW16 KF16 Flange-Centering O-Ring with Fine Filter

ISO-KF and NW Sintered Metal Filter Centering Ring NW-16、NW-25、NW-40、NW-50 Supplier With fine filter (sintered porous metal filter or choose wire mesh f...

View Detail -

NW50 KF50 Vacuum Flange Centering ring with Sintered Metal Filter, stainless steel, 50 ...

NW50 KF50 Centering ring with Sintered Metal Filter, stainless steel, 50 ISO-KF Product material: stainless steel 304,316 Installation method: use with clam...

View Detail -

NW16 KF16 KF Centering Ring to Sintered Metal Filter

NW16 / KF16 KF Centering Ring to Sintered Metal Filter • NW16 (KF16, QF16) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Pore Size•...

View Detail -

KF25 and NW25 Centering Ring with Sintered Metal Filter

NW25 / KF25KF Centering Ring with Sintered Metal Filter • NW25 (KF25, QF25) Series• Viton (Fluorocarbon, FKM) O-Ring• Viton: 200°C Maximum• 0.2 µm Pore Siz...

View Detail -

Monocrystalline silicon pressure transmitter sintered metal porous filter disc

Using single crystal silicon piezoresistive technology pressure sensor, process industry liquid level measurement applications sintered filter disc material:...

View Detail -

Porous sintered metal filter of ozone and air in water

The manufacturing process of large diameter (80-300 mm) discs of sintered stainless and corrosion-resistant steels is described. The characteristics of the i...

View Detail -

Sintered porous metal filter disc 20 micron for Gas purification and analysis

Achieve Unparalleled Gas/Solids Separation with HENGKO's Sintered Stainless Steel Filter Discs! Our filtration systems, featuring sintered stainless ...

View Detail -

sintered metal round depth filter sheets for cannabis oil production

Filtration In the production of stable cannabinoid products filtration is an essential step. To remove the waxes, fats and oil from the winterization a multi...

View Detail -

Sintered metal Gas / Solids Venturi Blowback (GSV) GSP filter OEM Services

Custom Sintered metal Gas/Solids Venturi Blowback (GSV) GSP filter Sintered metal filters have been used for hot gas filtration in various plants in the che...

View Detail -

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion

Stainless Steel Porous Metal Sheets SS316 Filter for Hydrogen Gas Diffusion Unlock the Versatility of Sintered Metal Elements with HENGKO! Our sintered meta...

View Detail -

HENGKO Sterilizing Grade Media Bacteria Filtration 0.2 5um Filter Media Sintered Porous...

Introducing HENGKO's Sterilizing Grade Porous Metal Filter for Medical and Life Science Applications! HENGKO's newly developed porous metal filter is...

View Detail -

Porous Metal Filter Sintered Stainless Steel Disc Filter for Fiberf Yarn Production / P...

Porous Metal Filters HENGKO's porous metal filter design provides increased life and performance to polymer spin pack filtration. The filter is a sintered,...

View Detail -

47mm Porous Disc Filter 316L SS Sintered Metal Filter for Laboratory Bench Scale Testing

HENGKO’s bench-top filter (47mm disc test filter), our 47mm disc filter, is a simple, inexpensive way to effect liquid-solid and gas-solid separations with e...

View Detail -

Industry Stainless Steel Powder Sintered Metal Filter Media For Fire Protection

Experience Unparalleled Safety and Efficiency with HENGKO's Gas Sensor Housings! When it comes to protecting your gas sensors and ensuring a secure environm...

View Detail -

Sintered Stainless Steel Sanitary Tri Clamp Filter Disc with Viton O-Ring frit Gasket f...

At HENGKO® we try to help our customers build high-quality, safe, and precise operations for processing hemp. The best CBD extracts equipment that we’re rec...

View Detail -

In-Line Porous Metal Sintered Filter Disc Strainers Filter Manufacturer -HENGKO

HENGKO manufactures spare washers for Venus, Kitty, Class, and Musa Moka pots. The package includes a washer and a coffee filter plate. Gasket diameterPlease...

View Detail -

sintered metal stainless steel 316L bronze porous air filtration filter cylinder/candle

Introducing HENGKO's Candle Filters: Tailored Solutions for Your Industrial Filtration Needs! Product Features:- Optimal Filtration: Our candle filters are ...

View Detail

Main Features:

The Sintered Stainless Steel Filter Disc boasts high mechanical strength, good rigidity, and plasticity,

as well as excellent resistance to oxidation and corrosion. It does not require additional skeleton

support protection, making installation and use simple and easy to maintain. This filter disc can be

sintered with 304 or 316 housing, bonded, and machined to meet specific project requirements.

Sintered stainless steel filter discs are versatile components used in various industries for filtration purposes. These discs are manufactured through a process called sintering, where stainless steel particles are compacted and heated to form a porous structure. Here are some features and functions of sintered stainless steel filter discs:

Features:

1. Stainless Steel Material: Sintered filter discs are made from high-quality stainless steel, which offers excellent corrosion resistance and durability.

2. Porous Structure: The sintering process creates a porous structure with uniform pore sizes, allowing for efficient filtration and separation of particles.

3. Wide Range of Pore Sizes: These filter discs are available in a wide range of pore sizes, making them suitable for filtering various substances from coarse to fine particles.

4. High Filtration Efficiency: The uniform and controlled pore size distribution ensures high filtration efficiency while maintaining a low pressure drop.

5. Chemical and Thermal Resistance: Sintered stainless steel filter discs can withstand a wide range of chemical and thermal conditions, making them suitable for diverse applications.

6. Easy to Clean and Reuse: These filter discs can be easily cleaned and reused, reducing the need for frequent replacements and minimizing waste.

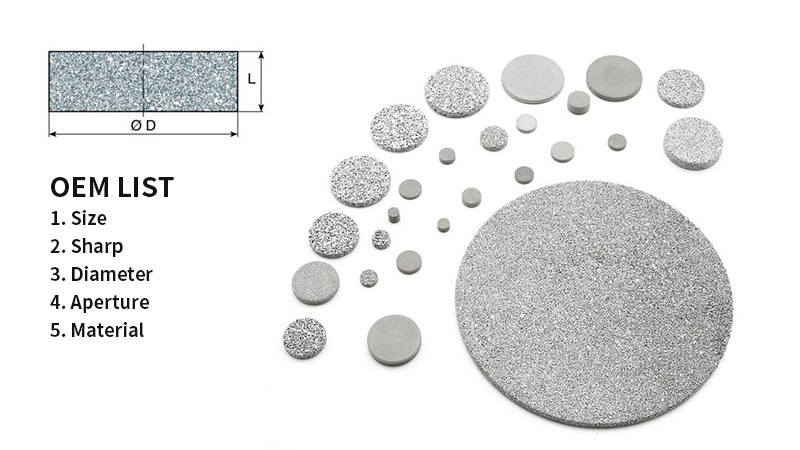

7. Customizable Shapes and Sizes: Manufacturers offer customization options for shapes and sizes to fit specific filtration equipment and applications.

8. Rigidity and Stability: The sintering process provides the filter discs with structural rigidity and stability, ensuring they retain their shape and performance during use.

Functions:

1. Filtration: The primary function of sintered stainless steel filter discs is to effectively filter and remove contaminants, impurities, or particles from liquids or gases.

2. Separation: These filter discs can be used to separate different substances based on their particle size, ensuring the desired components are retained or removed from the mixture.

3. Protection: Sintered stainless steel filter discs are used to protect sensitive equipment, pumps, and instrumentation from damage caused by particles or debris.

4. Purification: They are employed in purification processes to refine liquids and gases, ensuring high-quality end products.

5. Venting and Air Flow Control: Filter discs with controlled porosity are used for venting applications, allowing air or gas flow while preventing the passage of contaminants.

6. Fluidization: In certain applications, the filter discs aid in fluidization processes, helping to control the flow and distribution of gases or liquids through a bed of particles.

7. Dust and Emission Control: Sintered stainless steel filter discs are used in industrial settings to control emissions, capturing dust and particulate matter to comply with environmental regulations.

8. Catalyst Support: In some cases, these filter discs serve as catalyst support structures in chemical processes, enhancing reaction efficiency and facilitating separation after the reaction.

These features and functions highlight the importance and versatility of sintered stainless steel filter discs in numerous industrial applications where filtration and separation play a crucial role.

If you have higher requirements for the filtration area and flow control data requirements, HENGKO professional engineer team

will design best solutions of sintered metal filter disc to meet your high requirements and standards projects.

Why HENGKO Sintered Filter Disc

HENGKO is a well-known manufacturer of porous stainless steel disc filters that are tailored to meet various application requirements.

Our products are designed with innovation and customization to ensure that you get the perfect product for your needs.

We take pride in our long-standing history of supplying high-quality products, which are commonly used in superior industrial filtration,

dampening, sparger, sensor protection, pressure regulation, and many other applications. Our products are manufactured to meet CE

standards and are known for their stability and longevity.

At HENGKO, we provide comprehensive support, from engineering to aftermarket services, ensuring that you get the help you need

throughout the entire product lifecycle. Our team of experts has extensive experience in various chemical, food, and beverage

applications, making us the perfect partner for your filtration needs.

✔ PM Industry-renowned manufacturer of porous stainless steel disc filters

✔ Unique customized designs as different size, materials, layers and shapes

✔ High quality products strictly as CE standard, Stable shape

✔ Service from Engineering up to aftermarket support

✔ Expertise in various applications in chemical, food, and beverage industries

Application of Stainless Steel Filter Disc :

In our experience, we have found that powder porous metal sintered filter discs are highly effective in a variety of industrial applications.

These filter discs are ideal for use in distillation, absorption, evaporation, filtration, and other processes in industries such as petroleum,

refining, chemical, light industry, pharmaceutical, metallurgy, machinery, ship, automobile tractor, and more. They are particularly effective

in removing droplets and liquid foam entrained in steam or gas, resulting in high-quality output.

Liquid Filtration

Stainless steel filter discs are widely used for liquid filtration applications. They can be used for filtering water, chemicals, oils, and other liquids. The wire mesh is designed to trap particles of different sizes, ensuring that the filtered liquid is free of contaminants.

Gas Filtration

Stainless steel filter discs can also be used for gas filtration applications. They are commonly used in the automotive industry to filter air before it enters the engine. They can also be used in industrial settings to filter gases such as nitrogen, oxygen, and hydrogen.

Food and Beverage Filtration

Stainless steel filter discs are safe for use in food and beverage filtration applications. They can be used to filter liquids such as wine, beer, and fruit juices. The wire mesh is designed to trap particles and impurities, ensuring that the filtered product is pure and safe for consumption.

Pharmaceutical Filtration

Stainless steel filter discs are commonly used in pharmaceutical filtration applications. They can be used to filter liquids and gases in the production of drugs and other pharmaceutical products. The wire mesh is designed to trap bacteria and other contaminants, ensuring that the final product is safe and effective.

With our commitment to high-quality products, expert support, and innovative designs, HENGKO is your ideal

partner for all your sintered filter disc needs.

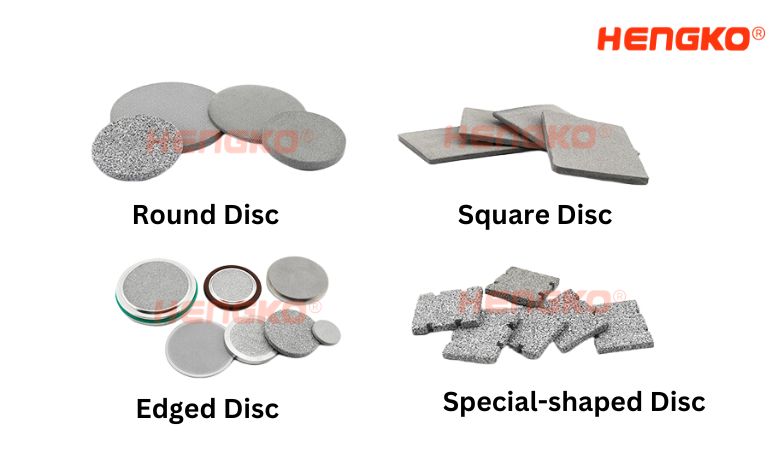

Types of Sintered Metal Filter Disc

Sintered metal filter discs come in various types, each designed to cater to specific filtration needs and applications. These types are differentiated based on their material composition, pore size, and intended use. Here are some common types of sintered metal filter discs:

1. Stainless Steel Sintered Filter Disc: The most common type, made from stainless steel, offers excellent corrosion resistance and durability. It is widely used in various industries for general filtration applications.

2. Bronze Sintered Filter Disc: Bronze sintered filter discs are known for their higher porosity and are often used for filtering liquids and gases in applications requiring fine filtration.

3. Nickel Sintered Filter Disc: Nickel sintered filter discs are utilized in environments with high temperatures and aggressive chemical conditions, thanks to nickel's exceptional resistance to corrosion.

4. Copper Sintered Filter Disc: Copper sintered filter discs find application in filtering gases and liquids while also offering good thermal conductivity.

5. Titanium Sintered Filter Disc: Titanium sintered filter discs are preferred in applications where high strength, low weight, and excellent corrosion resistance are essential.

6. Inconel Sintered Filter Disc: Inconel sintered filter discs are used in extreme temperature and corrosive environments, making them suitable for challenging filtration tasks.

7. Monel Sintered Filter Disc: Monel sintered filter discs are highly resistant to corrosion, making them ideal for filtration in marine environments and chemical processing.

8. Hastelloy Sintered Filter Disc: Hastelloy sintered filter discs are employed in applications requiring resistance to a wide range of corrosive media.

9. Tungsten Sintered Filter Disc: Tungsten sintered filter discs are utilized in high-temperature applications and for filtering aggressive chemicals.

10. Porosity-graded Sintered Filter Disc: These filter discs have varying pore sizes across the disc, allowing for more precise filtration in different sections.

11. Sintered Fiber Metal Filter Disc: Made from metal fibers, this type of filter disc offers higher porosity and surface area, enabling efficient filtration of fine particles.

12. Multi-Layer Sintered Filter Disc: Consisting of multiple layers with different porosities, this filter disc type provides enhanced filtration capacity and

can be used for complex filtration tasks.

It's essential to select the appropriate type of sintered metal filter disc based on the specific requirements of the filtration application, such as particle size, chemical compatibility, temperature, and pressure conditions. Each type of filter disc offers unique advantages and limitations, so choosing the right one ensures optimal filtration performance and durability.

Your Sintered Filter Engineered Solutions Best Supplier

Over the past 20+ years, HENGKO has provided solutions to numerous complex filtration and flow control

requirements for customers across a wide range of industries worldwide. Our team of experts can quickly

provide solutions tailored to your complex engineering applications.

Contact us today to discuss your project with the HENGKO R&D team, and we will find the best professional

sintered metal filter disc solution for your project within one week.

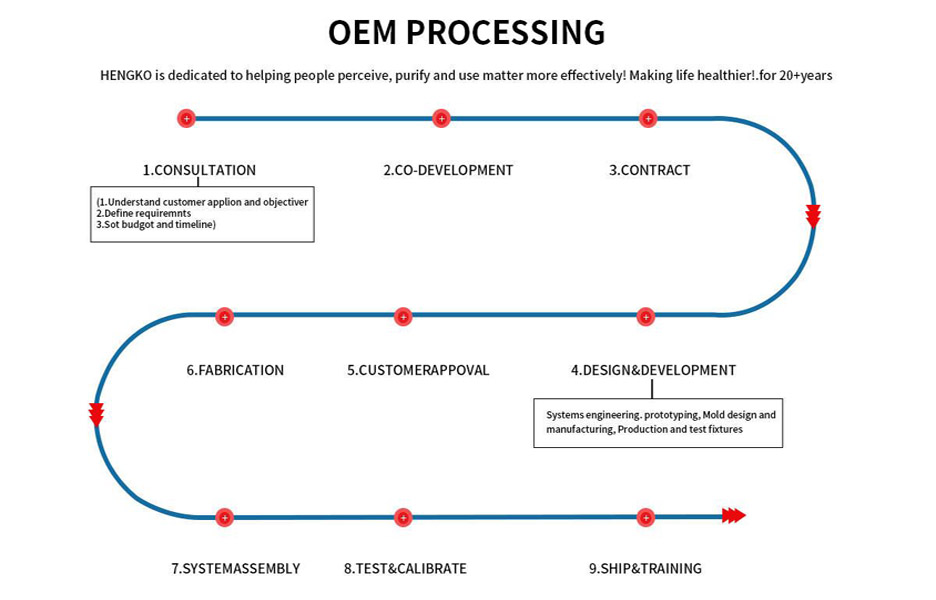

How to Customize Metal Sintered Stainless Steel Filter Disc

If you have a specific design for your projects and cannot find the same or a similar stainless steel filter disc product,

welcome to contact HENGKO. We will work together to find the best solution. Here is the process for OEM sintered

stainless steel filter disc:

1. Consultation and Contact HENGKO

2. Co-Development

3. Make a Contract

4. Design & Development

5. Customer Approval

6. Fabrication / Mass Production

7. System Assembly

8. Test & Calibrate

9. Shipping & Training

HENGKO is dedicated to helping people perceive, purify and use matter more effectively, making life healthier for over 20 years.

Please check the process and contact us to discuss more details.

HENGKO is an experienced factory that provides sophisticated sintered stainless steel filter elements for many applications.

We have worked with thousands of labs, universities, and R&D departments of brand companies worldwide. Many universities,

such as the following, have been our long-term partners. You are welcome to contact us and work with the HENGKO team.

You will get your solutions faster.

Popular FAQ about Stainless Steel Filter Disc

1. What is Stainless Steel Filter Disc ?

Also known as stainless steel filter discs and small mesh discs, these discs have the same pore size tiny holes that

trap very small particles.

Normal The wire mesh discs are often used in laboratories and gas-bubbling applications (sparging).

They’re made of 316L stainless steel because of excellent corrosion and abrasion resistance.

Stainless steel mesh filter discs are mainly utilized for filtration in diesel engines, pressure filter, chemical fiber and

plastic extruder, textile dope filtration, mine, water, foodstuff, and other industries. Sintered metal 316l stainless

steel filter disc facilitates screening or separation of one substance from another, making it possible for you to

remove unnecessary contaminants from solid or fluid.

The manufacturing process of the stainless steel filter disc involves three main steps.

The First step entails the selection of high-quality stainless steel wire, which is subsequently punched or weaved.

Also need to find a suitable material to wrap the edge of the wire mesh disc.

Also, choose different pore sizes of 316L stainless steel powder to put together in the middle and sintering.

Stainless steel mesh discs can design and make into different shapes, weaving techniques, filter precision, and

edge wrapping materials, among other features. So you can design this type of metal filter disc to fulfill your

needs like flow rate, filter particle size, physical space limitations, and contact liquid.

As one of professional stainless steel filter disc supplier, You are Welcome to visit our Factory to face to face

to talk more details for your projects, we also have sign non-disclosure agreement for many filtration

project for our clients.

2. What are the Main Features of Sintered Filter Disc?

1. High strength and frame stability for long service life.

2. Excellent resistance to corrosion, acid, alkali, and abrasion.

3. Can use high heat resistance under temperatures ranging from -200 °C to 600 °C.

4. Various filter ratings to choose or customize and great filter precision for different applications.

5. Good dirt holding capacity.

6. Easy to clean and reusable, reducing downtime and saving cost.

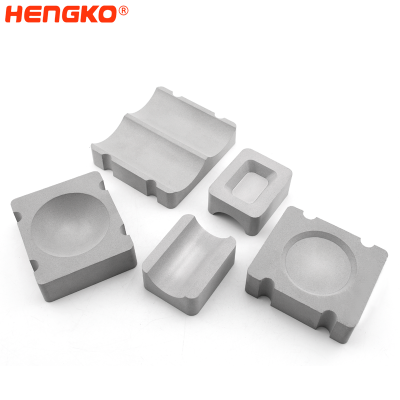

7. According to various project demands, Sintered Metal Filter Disc can be shaped into round, square,

rectangular, oval, ring, and others. Single layer or multi-layer can be chosen.

So Reliable operation with high online time and low maintenance; Demonstrate new technology

at a commercial scale.

3. What are Sintered Filters Used For ?

Sintered filters have been designed and applied as a new fine filtration material for the food, beverage,

water treatment, dust removal, pharmaceutical, and polymer industries because of the excellent

performance of sintered filters, including the high mechanical strength of sintered filters and the wide

range of filtration grades.

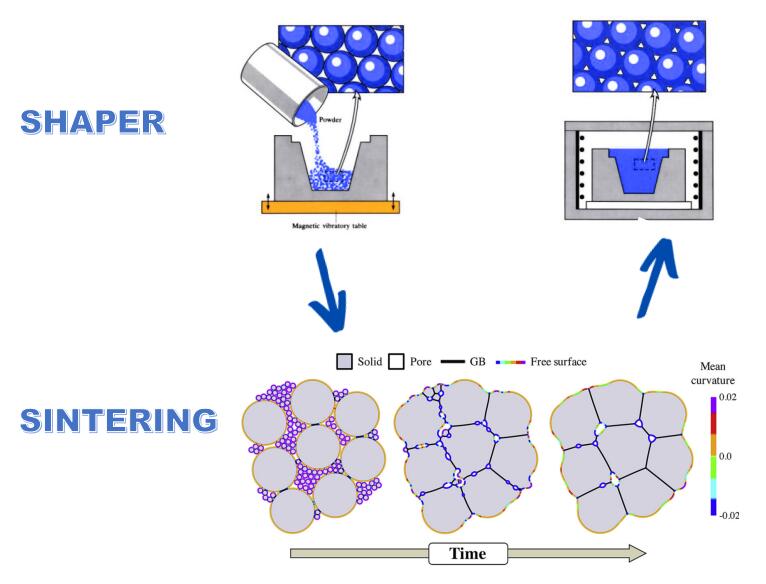

4. How does Sinered Filter Disc Work ?

In brief, the production process of sintered filters consists of 2 steps

1. Shaping

2. Sintering

However, before shaping and sintering, we must confirm with the customer the design, size, porosity,

flow requirements, material, and whether or not the filter has a threaded housing for easy installation.

The production steps of the sintered cartridge are as follows.

5. What Kind of Stainless Steel is main used for Filter Disc ?

The key grades of stainless steel powder appropriate for the production of stainless steel type of

sintered filter disc comprise:

1.) Stainless steel 316, comprised of manganese, silicon, carbon,nickel and chromium elements.

2.) Stainless steel 316L, Has a lower quantity of carbon content in comparison to stainless steel 316.

food grades for many applications included Food and Food and medical filtration etc

3.) Stainless steel 304, Constitutes nickel and chromium metals that are non-ferrous elements.

4.) Stainless steel 304L, Has a higher quantity of carbon content in comparison to stainless steel 304.

sure the price will be lower than 316L, 316, etc

6. How do you Clean Stainless Steel Wire Mesh Filter Disc?

There are several methods of cleaning stainless steel filter discs, with the choice of each method

depending on your type and level of operation.

Let’s look at some of the common methods of how to clean metal filter discs.

1) Blowback and Backwash Flushing

It is one of the simplest methods of cleaning filter discs.

For backwash flushing to work successfully, it depends on the reverse flow of fluid to dislodge

and carry particles away from the media structure.

The fluid used is normally filtrated or another process-compatible fluid.

The blowback and backwashing technique relies on loose attachment of the particles on or

within the holes of the filter mesh.

Using gas as the pressure source instead of liquid generates much turbulence as the generated

pressure forces the gas/liquid mixture through the filter disc mesh.

2) Soak and Flush

Cleaning stainless steel filter discs refer to using a detergent solution.

In this technique, you allow the filter disc to soak adequately for the action of the detergent to

loosen particles and flush them out of the filter media.

In a laboratory, you can carry out this procedure in processing stainless steel filter discs or with small

components.

3) Circulation Flows

In this method of cleaning the wire mesh filter disc, you need a cleaning system to help pump and

circulate a cleaning solution across the filter mesh until it is clean.

The circulation is usually in the opposite direction from which the filter disc mesh was soiled.

You must filter the cleaning solution before returning it to the filter media.

4) Ultrasonic Baths

This technique requires special equipment that employs ultrasonic sound waves to trigger off

particles and remove them from the filter mesh.

You can use laboratory models of this equipment to easily clean small stainless steel filter discs,

whereas bigger ones need big tank equipment with high power inputs.

Ultrasonic cleaning, in conjunction with the right detergent solution, is the most efficient method of

cleaning filter discs, particularly in the case of deeply embedded particles.

5) Furnace Cleaning

It is also a simple technique of cleaning metallic filter discs by volatilizing or burning biological or

organic compounds. It is most effective for removing polymer materials.

Furnace stainless steel filter disc cleaning is suitable for substances that leave no residual ash.

Otherwise, you will need an additional cleaning method to remove the ash residue.

6) Hydro Blasting

Hydro blasting cleaning techniques usually supersede other cleaning techniques when the particles

have grossly obstructed the holes of the filter mesh.

You can employ this method to clean, for example, filter discs in cross-flow tubes.

The high-pressure water jet removes the trapped particles through high-energy impaction.

It does not go very deeply into the filter mesh; however, in most instances, the obstruction may be only

at the filter media surface.

It is commonly applied in plants, and usually used to clean heat exchanger tubes.

7. Which Factors should you Consider when Choosing Stainless Steel Filter Disc?

When Selecting the right sintered metal filter disc to ensure the efficiency of your filtration system,

therefore, you should consider the following factors when choosing a stainless steel filter disc:

-

Type of Filter Media

There are different filter media types, such as random metal fiber, photo-etched, and sintered

filtration media, each with its advantages and disadvantages.

Therefore, you must choose a stainless filter disc with the right filtration media for your applications.

-

Type of Stainless-Steel Used

Stainless steel comes in various kinds, with each type having advantages that are fit for different purposes.

Before buying one, it is crucial to ascertain the individual characteristics of the material used to make a filter disc.

Such characteristics include pressure, temperature limits, and reactions to other compounds and conditions.

-

Mesh Number

It is the number of holes per inch of a stainless steel filter mesh.

If the mesh number is big, it indicates numerous holes per inch of the filter disc mesh.

It also signifies that the individual holes are small and vice versa.

-

Mesh Size

The mesh size designates the size of individual holes on the stainless steel filter disc mesh.

It is always measured in millimeters, microns, or fractional inches.

-

Strand Diameter

It is a crucial consideration when selecting a stainless steel filter disc.

When a wire has a broad strand diameter, it signifies that it has tiny mesh holes.

In short, the larger the strand's diameter, the greater the mesh number of the sintered filter disc.

The diameter of the strand is a percentage of the overall surface area of the stainless steel filter mesh, i.e.,

the percentage of open area. Therefore, having a greater percentage of the open area indicates

that the filter disc has a high flow.

-

Filament Diameter

This parameter affects the mesh openings and the percentage of the open area of the filter mesh.

-

Fluid Compatibility

You should ensure that the stainless steel filter disc is well-matched with the fluid you want to filter.

It helps avoid any reaction between the filter disc and the fluid involved since any reaction will

negatively impact the quality of the filtration process.

8. ls there Shape Limitation for Stainless Steel Wire Mesh Filter Disc?

No, you can design as your project requires. share your size, pore size, flow control etc and

contact us for details.

9. What Are the Advantages of Sintered Filter Discs?

Four Main Advantages Include:

1.) Durability

Sintered Stainless steel filter disc is highly durable, making it the ideal choice for your applications.

It is long-lasting since it does not react with several fluids.

It ensures you have the full potential of your stainless steel sintered mesh filter disc.

Because of longevity, it will reduce your operating costs in the long term.

2. ) Versatility

Stainless steel sintered filter discs give you the freedom to use in various applications because of the

unique chemical and physical properties of stainless steel filter discs.

These features comprise corrosion, acid and alkali resistance, operating pressure and temperature,

and compatibility with various fluids.

3.) Efficiency

The type of metal sintered filter disc ensures efficiency in its performance.

The efficiency of sintered stainless steel filter disc guarantees that you can easily reach the desired

level of filtration.

4.) Ease of Cleaning

Wire mesh sintered filter discs made of stainless steel high level of hygiene since they are easy to clean.

Using them in hygiene-sensitive applications like the food and beverage industry makes it possible.

Moreover, the silvery appearance of stainless steel boosts the aesthetic appeal of the filter disc while

ensuring the general hygiene of your operations.

Contact Us if Want to Solution Details for the Stainless Steel Filter Disc.