Diffusion Stone And Carbonation Stone OEM Special Manufacturer

HENGKO's precisely engineered Sintered Metal Special Diffusion Stones and Carbonation Stones serve a wide array of industries including pharmaceuticals, food processing, both commercial and domestic beverage sectors, wastewater treatment, and petrochemicals, among others. Our tailor-made OEM services allow us to create distinctive Diffusion and Carbonation Stones, designed to enhance the performance of your aeration systems across a variety of processes such as fermentation, oxidation, and gasification.

Our dedication to outstanding quality, dependability, and innovation leads us to provide a diverse range of custom sintered metal Diffusion and Carbonation Stones, carefully designed to cater to your particular needs. If you have specific diffusion needs for an upcoming project, or wish to upgrade an existing aeration system, HENGKO's experienced team of engineers and technicians is ready to assist. We'll work closely with you to deliver the most efficient solution that fits your project or device requirements.

* OEM Diffusion Stone And Carbonation Stone Materials

For more than 18 years, HENGKO has specialized in the production of Sintered Metal Filters, establishing itself as a leading enterprise in the field. Today, we proudly provide high-quality materials that include, but are not limited to, variants of 316 and 316L Stainless Steel, Bronze, Inconel Nickel, as well as a selection of Composite Materials.

* OEM Diffusion Stone And Carbonation Stone By Pore Size

To achieve an optimal diffusion effect, the initial step is selecting a sintered diffusion stone with the right pore size. This choice should align with your technical requirements. If you have any queries regarding the selection of pore size for the diffusion stone, feel free to reach out to us.

* OEM Diffusion Stone And Carb Stone By Design

When it comes to aesthetic design and size, we currently offer eight diverse options for you to choose from. Our range includes simple aeration stones with inlet connectors, various models with different threaded joints, square and other regular shapes, as well as the option to customize special shapes. Regardless of your needs, we are prepared to cater to all your OEM requirements and provide a tailored solution.

SFB Series Aeration Stone

SFC Series Aeration Stone

SFH Series Aeration Stone

SFW Series Aeration Stone

Multi-joint Diffusion Stone for Bioreactor

Disc Design Diffusion Stone

Mushroom Head Shape Aeration Stone

OEM Special Diffusion for Semiconductor Filter

* OEM Diffusion Stone And Carbonation Stone By Application

Our sintered metal diffusion stones and carbonation devices are designed to enhance the efficiency of aeration systems in your industrial processes. These sparger components, made from 316L stainless steel, offer superior physical properties like resistance to corrosion, acids, and alkalis, coupled with a robust and stable structure. Whatever your application or project might be, don't hesitate to contact HENGKO for more detailed information.

* Why Choose HENGKO OEM Your Diffusion Stone And Carbonation Stone

HENGKO stands as a distinguished and seasoned manufacturer of diffusion and carbonation stones, which are utilized across an array of sectors such as food and beverage, pharmaceuticals, and water treatment.

Below are some key reasons why HENGKO could be your ideal OEM partner for sourcing diffusion and carbonation stones:

1. Superior Product Quality:

HENGKO is committed to crafting diffusion and carbonation stones that meet or even exceed industry norms.

Employing top-tier materials and sophisticated production techniques, we ensure our products are durable, proficient, and effective.

2. Tailored Options:

We offer a broad spectrum of customization alternatives to cater to your distinct needs.

Our offerings include various materials, pore sizes, shapes, and sizes. Additionally, we provide personalized packaging

and labelling services to enhance your brand's visibility.

3. Competitive Pricing Strategy:

Balancing premium quality with cost-effectiveness, HENGKO's competitively priced products make us a preferred choice

for businesses seeking value for money. We offer discounts on bulk orders and are ready to collaborate with you to devise

a pricing strategy aligned with your budget constraints.

4. Outstanding Customer Service:

HENGKO boasts a skilled team of representatives, well-versed in guiding you through product selection,

customization, and providing technical support. Our team is dedicated to offering swift and responsive

service to guarantee your satisfaction.

5. Speedy Delivery:

Thanks to HENGKO's extensive global logistics network, we are able to deliver our products

efficiently and promptly. We also offer expedited shipping and other delivery alternatives to cater

to your specific needs.

In conclusion, HENGKO stands as a trustworthy and dependable provider of diffusion and carbonation stones.

We are committed to aiding you in enhancing your product quality and operational efficiency.

* Who We Worked With us

With a wealth of experience in designing, developing, and producing sintered filters, HENGKO has established enduring collaborations with numerous renowned universities and research laboratories across different domains. If you're seeking customized sintered filters, don't hesitate to contact us. At HENGKO, we're committed to offering you the optimal filtering solution that addresses all your filtration needs.

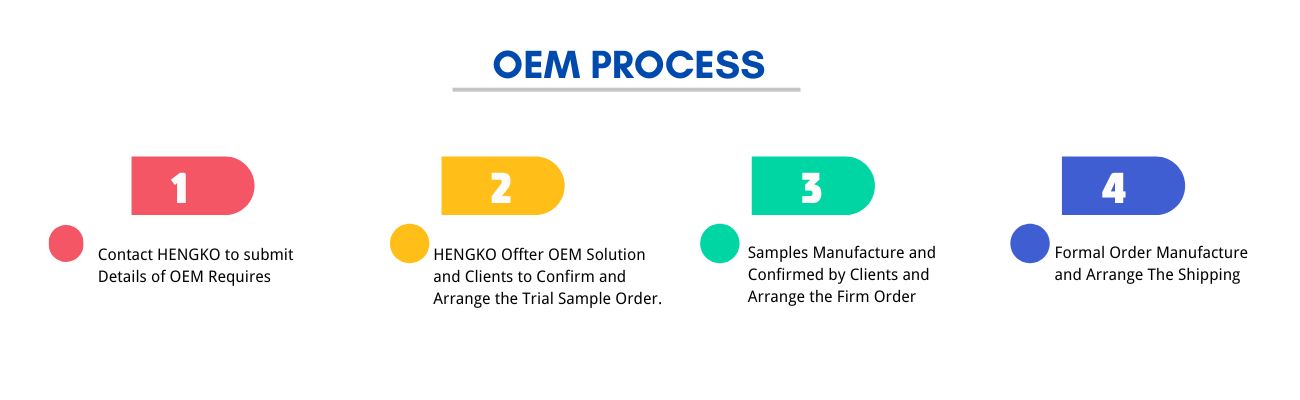

* What You Should Do to OEM Diffusion Stone And Carbonation Stone- OEM Process

If you have an idea or concept for a custom OEM Sintered Carbonation Stone, we warmly invite you to connect with our sales team to discuss your design intentions and technical specifications in more detail. For insight into our OEM process, please refer to the following information. We hope it facilitates a seamless collaboration between us.

* FAQ about Diffusion Stone And Carb Stone ?

As Follow are some FAQ about sintered metal Carbonation Stone often asked, hope those will be helpful.

A sintered metal diffusion stone is a small, porous device used to efficiently and evenly disperse gases or liquids into a larger container. It's made by heating and compacting metal powder until it forms a solid piece with millions of tiny interconnected pores. These pores allow the desired gas or liquid to pass through the stone and disperse into the surrounding environment in the form of fine bubbles or droplets.

Here are some key characteristics of sintered metal diffusion stones:

- Material: Commonly made from stainless steel, especially grade 316, known for its durability and corrosion resistance. Some stones can be made from other metals like titanium or bronze depending on the application's specific needs.

- Porosity: Different stones have varying pore sizes, measured in microns, affecting the size and flow rate of the dispersed bubbles or droplets. Smaller pores produce finer bubbles, ideal for applications requiring high gas absorption rates, like oxygenating wort in beer brewing.

- Applications: They are used in various industries:

- Brewing: Carbonating beer and cider, oxygenating wort.

- Pharmaceuticals: Sterile gas diffusion for drug production.

- Biotechnology: Oxygenating cell cultures for bacteria and yeast growth.

- Chemical processing: Aeration of tanks and reactors.

- Water treatment: Ozone or oxygen diffusion for disinfection.

- Wastewater treatment: Air diffusion for aeration and bacterial growth.

Sintered metal diffusion stones offer several advantages over other materials:

- Durability: They are strong and can withstand high pressures and temperatures common in industrial applications.

- Chemical resistance: The stainless steel construction makes them resistant to corrosion from many chemicals and cleaning agents.

- Uniformity: The controlled sintering process ensures consistent pore size distribution, leading to uniform gas/liquid dispersion.

- Easy cleaning: Their smooth surface and open pores facilitate easy cleaning and sterilization.

If you have any further questions about specific applications or aspects of sintered metal diffusion stones, feel free to ask HENGKO ! we are happy to delve deeper into their functionality and advantages.

A carb stone, also known as a carbonation stone, is a type of sintered metal diffusion stone specifically designed for carbonating beverages, primarily beer and cider. It works by diffusing pressurized carbon dioxide (CO2) gas into the liquid through its tiny pores, creating fine bubbles throughout the beverage. These bubbles then slowly dissolve, resulting in the familiar fizz and carbonation we enjoy in our drinks.

Here are some key points about carb stones:

- Material: Typically made from sintered stainless steel, just like other diffusion stones, due to its durability and corrosion resistance.

- Shape and Size: Usually cylindrical, with varying lengths and diameters depending on the intended application and tank size.

- Function: They are placed inside a beverage tank, often near the bottom, and CO2 gas is fed into the stone under pressure. The pores allow the CO2 to pass through and disperse as tiny bubbles throughout the liquid, efficiently carbonating the beverage.

- Advantages: Compared to other carbonation methods, carb stones offer several benefits:

- Controlled carbonation: Precise control over the carbonation level through CO2 pressure adjustment.

- Uniform diffusion: Fine bubbles ensure even distribution of CO2 throughout the beverage.

- Gentle carbonation: Minimizes turbulence and foam formation while achieving desired carbonation.

- Cost-effective: Relatively inexpensive compared to some other methods.

- Applications: While primarily used for beer and cider carbonation, they can also be used for:

- Oxygenating wort: Before fermentation in brewing, to promote healthy yeast growth.

- Adding CO2 to flat or under-carbonated beverages: For bottling or kegging.

- Scrubbing dissolved oxygen: In water or other liquids, if oxygen removal is desired.

However, carb stones also have some drawbacks:

- Clogging: Pores can become clogged over time with yeast sediment or proteins, requiring regular cleaning and sterilization.

- Maintenance: Monitoring CO2 pressure and ensuring stone placement for optimal diffusion is important.

- Potential contamination: Requires proper sanitation procedures to avoid bacterial infections.

Overall, carb stones are a popular and effective tool for achieving consistent and controlled carbonation in beverages, particularly in homebrewing and smaller breweries. Their ease of use, affordability, and ability to produce fine, smooth bubbles make them a valuable asset for brewers and beverage producers.

I hope this clarifies the role of carb stones in the world of beverage carbonation! If you have any further questions or would like to know more about specific aspects of their use, feel free to ask.

Sintered metal diffusion stones offer a range of benefits over other materials like ceramics or plastics, making them a popular choice in various industries. Here are some of the key advantages:

Durability: Sintered metal is incredibly strong and can withstand high pressures and temperatures, often encountered in industrial applications. This translates to a longer lifespan compared to more fragile materials like ceramic stones.

Chemical resistance: The stainless steel used in most sintered metal stones is highly resistant to corrosion from a wide range of chemicals and cleaning agents. This makes them ideal for use in harsh environments or with aggressive fluids.

Uniformity: Unlike some other materials, sintered metal allows for precise control over pore size distribution during the manufacturing process. This ensures consistent gas or liquid diffusion, leading to optimal performance and reduced waste.

Efficiency: The uniform and open pore structure of sintered metal stones minimizes resistance to gas or liquid flow. This results in efficient diffusion and minimizes gas usage compared to less effective materials.

Easy cleaning: The smooth surface and open pores of sintered metal stones facilitate easy cleaning and sterilization. This is crucial for maintaining hygiene and preventing clogging in applications involving food or pharmaceuticals.

Controllable pore size: Different applications require different pore sizes for optimal diffusion. Sintered metal allows for tailoring the pore size to the specific needs, optimizing performance for various gases, liquids, and flow rates.

Versatility: Sintered metal diffusion stones are suitable for a wide range of applications in various industries, from brewing and pharmaceuticals to wastewater treatment and chemical processing.

Additional benefits:

- Heat resistance: They can withstand high temperatures, making them suitable for hot liquids or gas diffusion at elevated temperatures.

- Non-stick surface: Their smooth surface minimizes the risk of residue build-up or clogging.

- Environmentally friendly: They are durable and have a long lifespan, reducing waste compared to disposable alternatives.

Overall, sintered metal diffusion stones offer a winning combination of durability, efficiency, and versatility, making them a valuable tool in numerous industries.

If you have any specific application in mind, I can delve deeper into how sintered metal diffusion stones can benefit your particular needs. Just let me know what you're interested in!

Sintered metal diffusion stones can be made from a range of metals, including 316L stainless steel, titanium, and bronze.

Carb stones are typically made from porous stones such as sintered stainless steel or ceramic.

Sintered metal diffusion stones are typically placed in a gas injection system and submerged in the liquid to be treated. The gas is then injected through the stone, which disperses the gas into the liquid.

Carb stones are typically placed in a vessel containing the liquid to be carbonated, and carbon dioxide is then injected through the stone, which disperses the gas into the liquid.

Yes, both types of stones can be cleaned using a variety of methods, including soaking in cleaning solutions, boiling, and autoclaving.

Both types of stones can last for several years with proper care and maintenance.

No, sintered metal diffusion stones and carb stones are designed for different applications and are not interchangeable.

Sintered metal diffusion stones and carb stones find application in a variety of industries, with some distinct preferences based on their specific functions. Here's a breakdown:

Sintered Metal Diffusion Stones:

- General Industries:

- Chemical processing: Aeration of tanks and reactors, gas-liquid reactions, ozone diffusion for disinfection.

- Wastewater treatment: Air diffusion for aeration and bacterial growth, oxygenation for sludge treatment.

- Water treatment: Ozone or oxygen diffusion for disinfection, removal of dissolved gasses.

- Biotechnology: Oxygenating cell cultures for bacteria and yeast growth, gas stripping from bioreactors.

- Power generation: Oxygenation of boiler feedwater to minimize corrosion.

- Food and Beverage Industry:

- Brewing: Oxygenating wort for yeast growth, carbonating beer and cider.

- Winemaking: Micro-oxygenation of wine during ageing.

- Food processing: Aeration of tanks for fermentation and storage, stripping unwanted gasses from liquids.

Carb Stones (Specifically for Carbonation):

- Beverage Industry:

- Beer and cider: Primary use for carbonating finished beer and cider, both commercially and in homebrewing.

- Sparkling water: Carbonating bottled or canned water.

- Other carbonated beverages: Soda, kombucha, seltzer, etc.

Additional Points:

- While both types utilize sintered metal, carb stones tend to be smaller and have finer pores for efficient carbonation.

- Some industries, like pharmaceuticals and fine chemicals, may use specialized sintered metal stones with controlled pore sizes for specific gas diffusion requirements.

- The versatility of sintered metal stones allows for their adaptation to various needs, expanding their potential applications across different industries.

If you'd like to know more about the specific uses of these stones in any particular industry, feel free to ask! I'm happy to delve deeper into their various applications.

* You May Also Like

HENGKO offers an extensive range of Sintered Metal Diffusion and Carbonation Stones, along with other sintered filter products for diverse applications. Please explore the following sintered filters. If any product captures your interest, feel free to click on the link to delve into more details. You're also welcome to reach out to us at ka@hengko.com for pricing information today.