OEM sintered metal sparger - Manufacturers, Suppliers, Factory from China

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for OEM sintered metal sparger, Metal Screen Filter , Ss Sintered Filter Cartridge , Relative Humidity Transmitter ,Electrochemical Gas Detector . We believe that you will be glad with our realistic selling price, high-quality products and solutions and rapid delivery. We sincerely hope you can give us an prospect to provide you and be your best partner! The product will supply to all over the world, such as Europe, America, Australia,Bangladesh , panama ,azerbaijan , Sao Paulo .With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

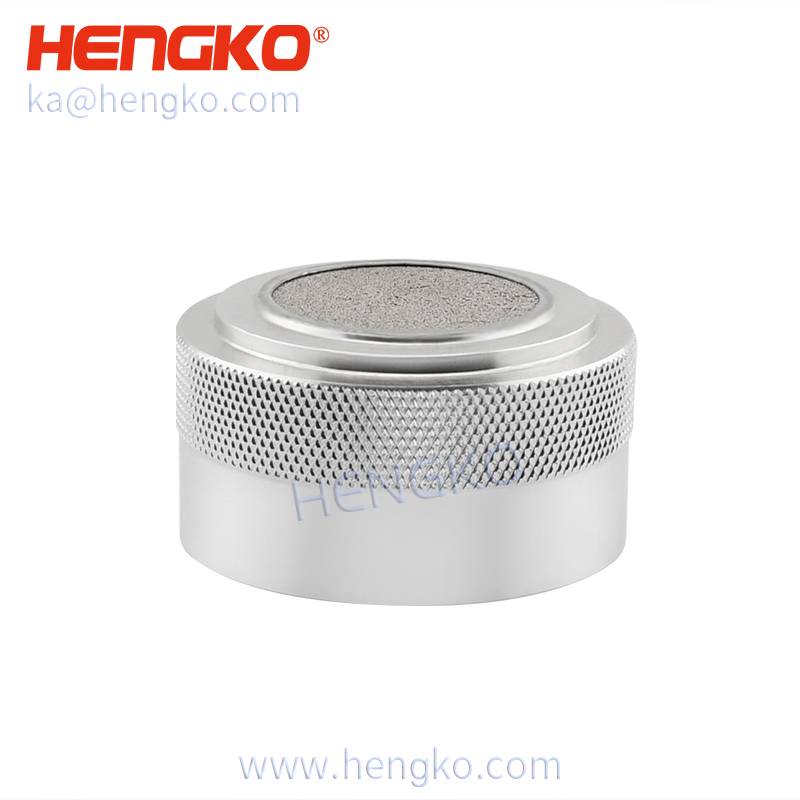

Related Products