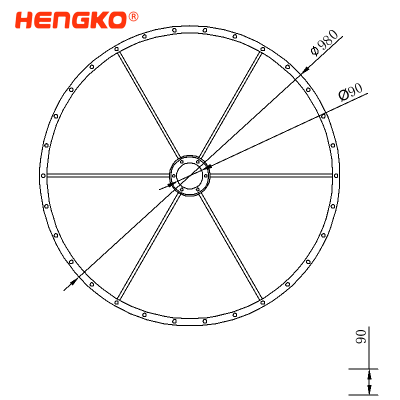

Multi-layer sintered stainless steel mesh plate fluidized bed equipment Distributor bottom filter for Biopharmaceutical Applications

Stainless steel mesh plate for fluid bed

Stainless steel mesh plate for fluid bed

Control of gas distribution, powdered material transmission, and fluidization operation has been widely used in industry procedures. While fluidization technology is an important method to transfer mass, heat, and chemical reactions in the chemical industry, in which, controlling gas distribution needs sintered wire plate with good permeability.

The HENGKO fluid bed plate provides uniform distribution of the air across the bed plate eliminating channeling and non-uniform fluidization patterns. The plate is constructed of sturdy, heavy gauge stainless steel to resist fraying and breakage, allowing a variety of tools to be used in product removal and cleanup.

Want more information or would you like to receive a quote?

Please click the CHAT NOW button at the top to contact our salespeople.

E-mail:

ka@hengko.com sales@hengko.com f@hengko.com h@hengko.com

Sintered multi-layer stainless steel mesh plate fluidized bed equipment Distributor bottom filter for Biopharmaceutical Applications

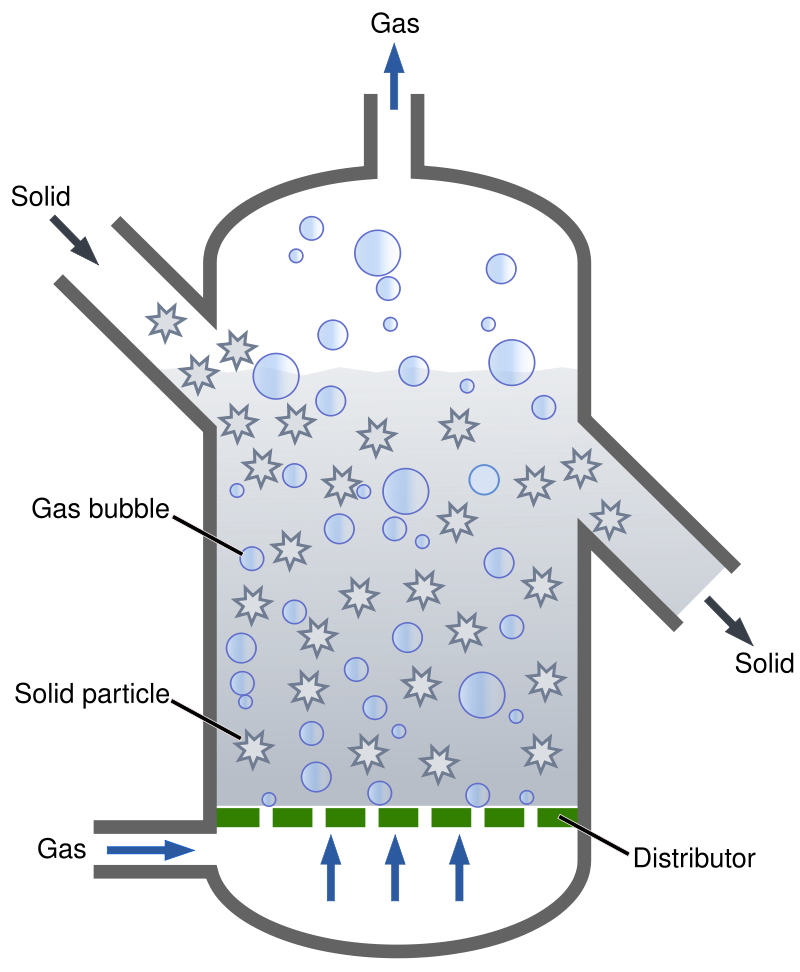

A fluidized bed is a physical phenomenon occurring when a quantity of a solid particulate substance (usually present in a holding vessel) is placed under appropriate conditions to cause a solid/fluid mixture to behave as a fluid. This is usually achieved by the introduction of pressurized fluid through the particulate medium. This results in the medium then having many properties and characteristics of normal fluids, such as the ability to free-flow under gravity, or to be pumped using fluid type technologies.

Fluidized beds are used for several purposes, such as fluidized bed reactors (types of chemical reactors), solids separation, fluid catalytic cracking, fluidized bed combustion, heat or mass transfer or interface modification, such as applying a coating onto solid items.

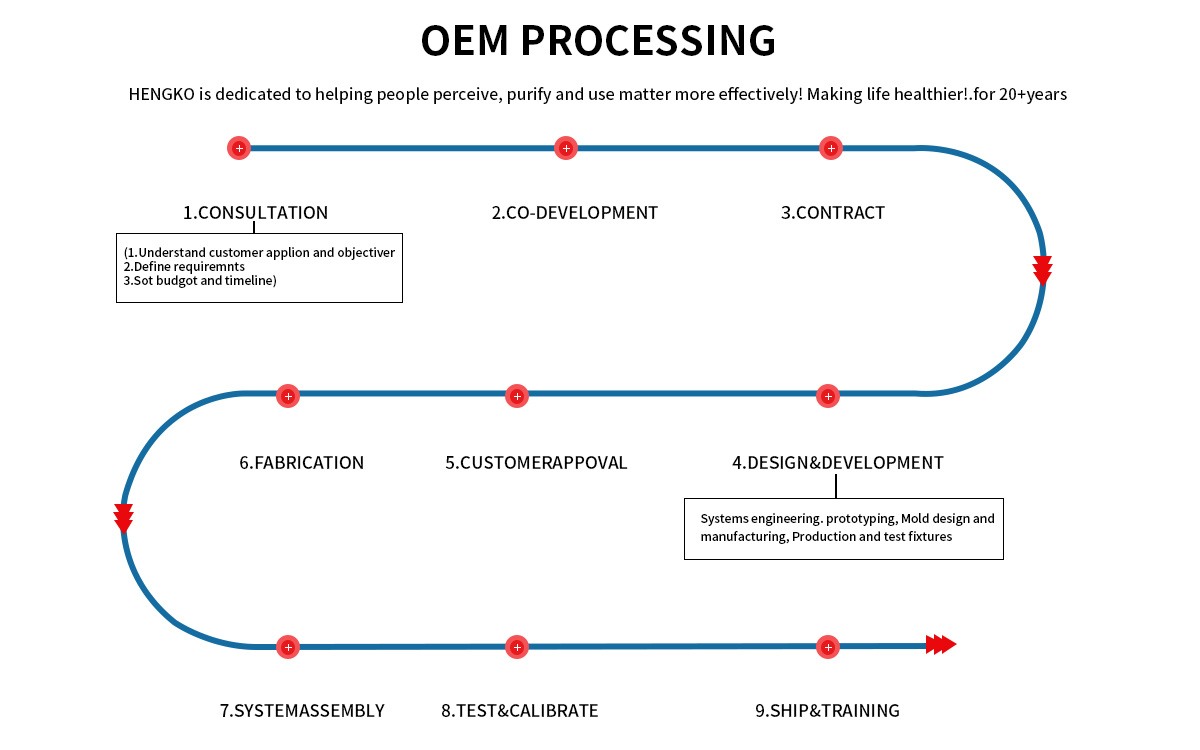

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!