316L Sintered stainless steel filter cartridge for gas solids separation

Filtration systems utilizing sintered metal filter elements have proven to be an effective and economical alternative to other separation equipment susceptible to pressure peaks, high temperatures, and aggressive environments. This includes bag houses, cyclones, electrostatic precipitators, and scrubbers. Sintered metal filters have demonstrated high-efficiency particle removal, reliable filtration performance, effective blowback cleaning, and long on-stream service life in many industrial applications utilizing calciners, incinerators, and fluid bed dryers.

Filtration systems utilizing sintered metal filter elements have proven to be an effective and economical alternative to other separation equipment susceptible to pressure peaks, high temperatures, and aggressive environments. This includes bag houses, cyclones, electrostatic precipitators, and scrubbers. Sintered metal filters have demonstrated high-efficiency particle removal, reliable filtration performance, effective blowback cleaning, and long on-stream service life in many industrial applications utilizing calciners, incinerators, and fluid bed dryers.

The sintered metal filter is well suited for dust removal and gas treatment, mainly where hot gasses and sparks are present. Continually updated government regulations impose stricter limits on the quality and quantity of gases emitted into the atmosphere. Bag filters are limited by the physical and chemical properties of the fabric medium, which in general forms cannot withstand high temperatures or corrosive atmospheres. The frequent and costly bag filter problems with fires, solids breakthrough, and media replacement are eliminated using a sintered metal filter element. Sintered metal filters have proven performance in the recovery of catalysts, products for chemical processing and pharmaceuticals applications, rock quarries, metal mining industry, power generating facilities, coal and coke handling Operations, and many other applications.

Key Features, Properties, and Applications of Sintered Metal Filters For Gas/Solid Separation

Customers and processes demand finer filtration and more reliable sintered filters. Sintered porous metal filter meets these criteria and offers high removal efficiency to meet tighter emission standards for today’s industrial applications. Developing a specially designed and engineered sintered porous metal filter with a stable porous matrix, precise bubble point specifications, close thickness tolerances, and uniformity of permeability assures reliable filtration performance, effective blowback cleaning, and long on-stream service life. The construction of sintered media can be tailored for specific applications. Sintered metal filters can be made from various alloys suited for corrosive and high-temperature applications. Precise furnace atmosphere control, sintering temperature control, and time at temperature assure “solids state diffusion bonding” at every contact point between adjacent particles in the porous structure.

This permanent construction allows the cartridge to be cleaned in various ways and without media migration. In-situ cleaning of process filters is by back blowing. Chemical cleaning with compatible materials or ultrasonic cleaning in a detergent solution removes insoluble contaminants from the filter.

Sintered metal powder stainless steel 316L industrial filter cartridge for gas solids separation

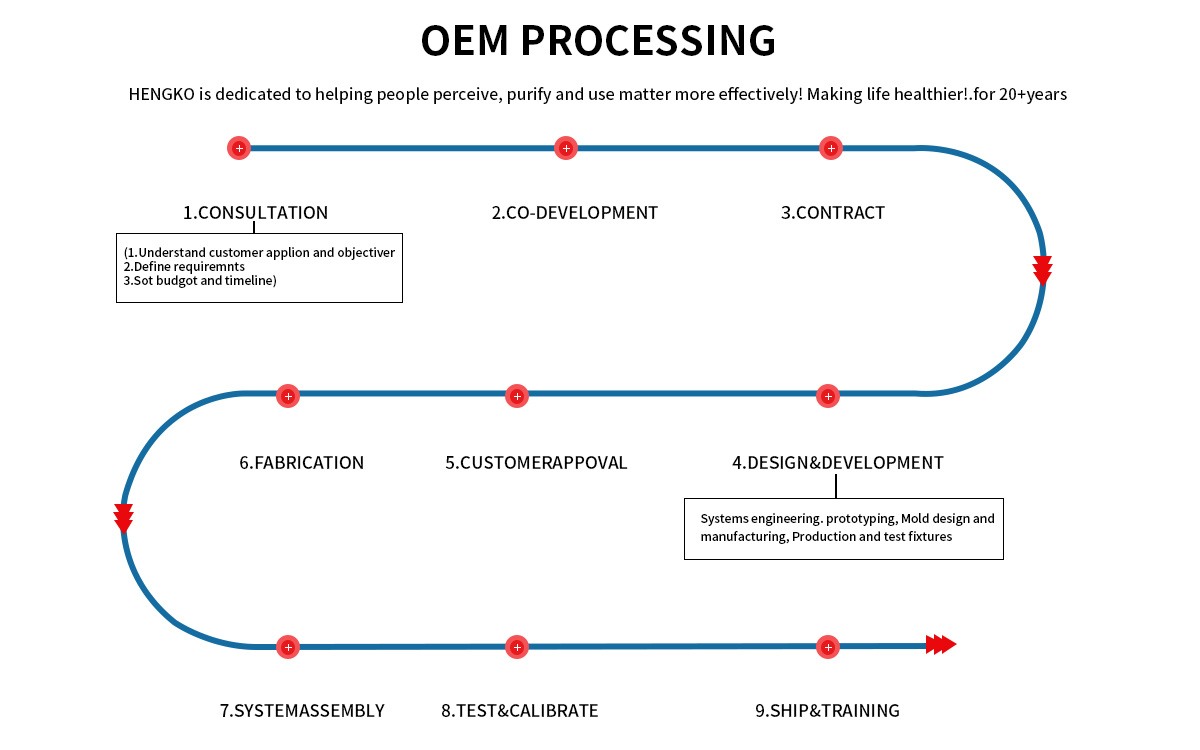

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!