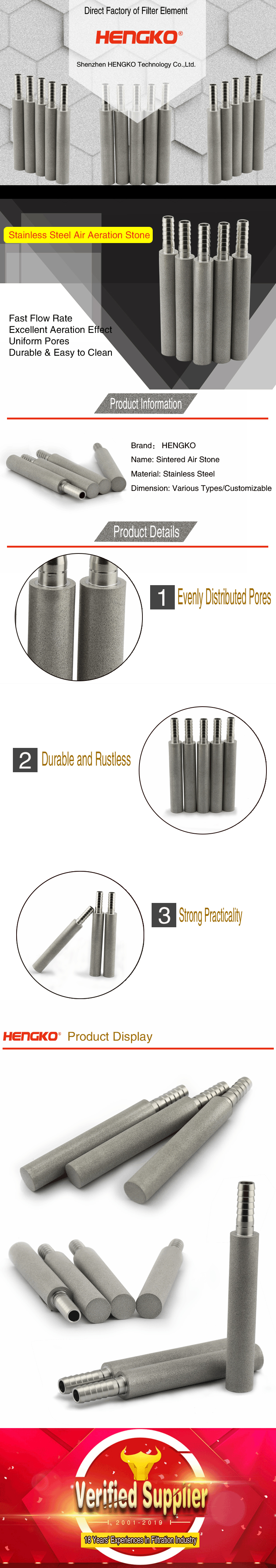

Stainless steel 316 micro sintered nitrogen diffusion stone with barb connector Used in the Coffee Industry

Coffee, like all other food & beverage products, must go through a preservation process to keep the beans fresh during storage and packaging before they reach the consumer. Coffee that is not properly stored after it is roasted will lose a large amount of carbon dioxide, which lessens its' flavor and speeds up the staling process. One of the most common ways to preserve the freshness of coffee is the use of nitrogen gas.

Storage

After roasting, coffee beans are often stored in large airtight containers for weeks if they are not ready to be packaged. This containers are flushed or purged with nitrogen gas to preserve the life of the coffee and to push out any inside oxygen that could reduce the quality of the coffee. An on-site nitrogen generator is ideal for coffee storage, because over time the generator will continuously push nitrogen into the containers to keep the coffee fresh. Since nitrogen is colorless and odorless, this has no effect on the flavor or appearance of the coffee over time.

Packaging

Once the coffee is ready to be packaged, it still needs to be preserved to increase the shelf-life of the product. The coffee beans are dropped into a packaging machine, usually into a funnel or hopper at the top, and then dropped through the machine into bags where they are flushed with nitrogen gas while the bags are filling and until they are sealed. Typically the purity of the nitrogen used in packaging is somewhere between 99 - 99.9%. Similarly, K-Cups and other coffee pod type products also utilize nitrogen in their packaging. As the cups are filled, they are flushed with nitrogen and then sealed to prevent oxygen and moisture from reaching the coffee. Oxygen levels are reduced to less than 3%, providing an even longer shelf life for these pods.

Nitro-Brewed Coffee

Major coffee houses have added the latest "nitro-brew" trend of coffee to their menus in recent years. Nitro-brew is coffee that is brewed with pressurized nitrogen gas, cooled down and stored usually in kegs and then served "on tap". Nitro-brew is typically sweeter than regular coffee and smoother and can often contain more caffeine than regularly brewed coffee. Different from coffee packaging, nitrogen is not used for preservation purposes in this case, but more for flavor and a different product quality. Consumers who typically add cream and sugar to black coffee are more fond of the already sweet nitro-brew. The same process is also able to be implemented into beer and various teas.

Nitrogen is essential to coffee manufacturers and coffee houses for both preservation needs and new, trendy products. Having an on-site gas generator for both packaging/storage and brewing is ideal for constant access to nitrogen and to have the ability to control the purities for various processes.

Applications:

feed water

sewage treatment

Stainless steel 316 micro sintered nitrogen diffusion stone with barb connector Used in the Coffee Industry

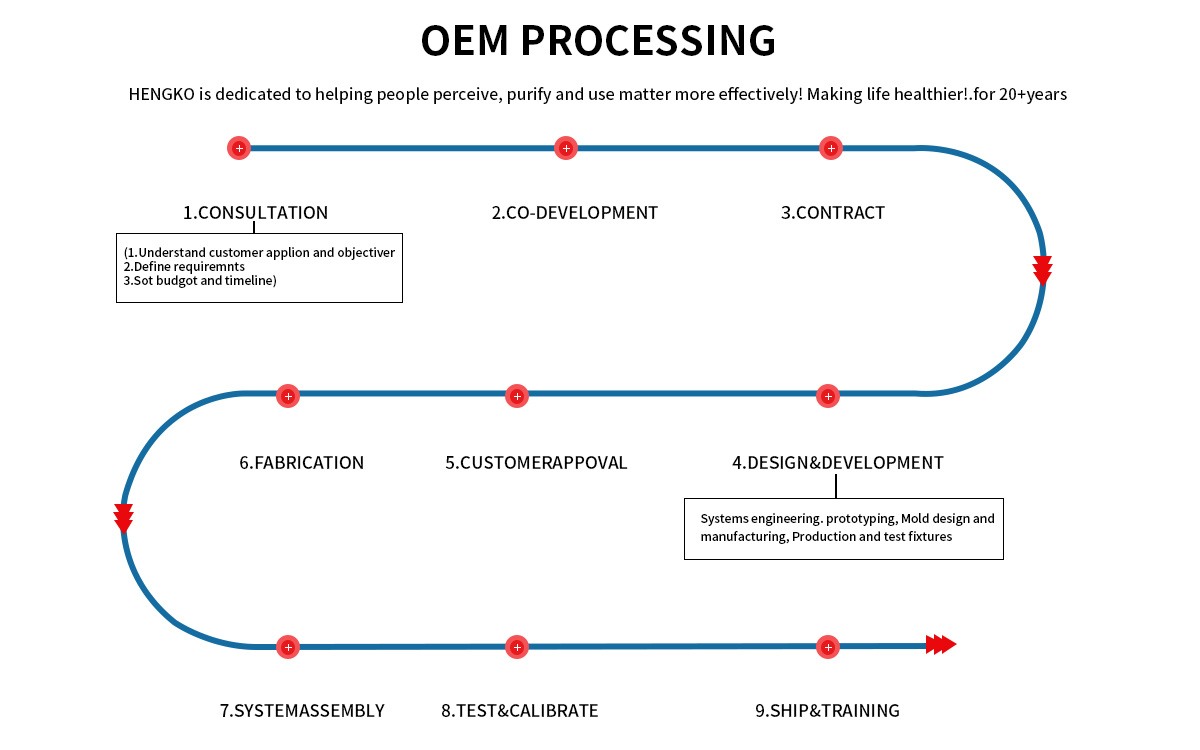

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!