Porous Metal Sintered Bearing

Porous metals are one of the many materials suitable for manufacturing bearings.

Porous metals are one of the many materials suitable for manufacturing bearings.

Benefits of Sintered Bearings

Powdered metals have a large number of benefits and advantages that allow them to be used effectively to produce high quality bearings. Some of these benefits are listed below.

Special surfaces. One of the benefits of powdered metals is that they can provide an excellent surface finish for bearings. When optimally processed, these materials can easily produce bearings with an excellent finish, making the surface not only attractive, but also resistant to wear and corrosion. Their increased surface strength allows bearings to be utilized in many of today's machines.

Excellent porosity. Another benefit of powdered metals is the excellent porosity they can have. Once powdered metals are machined, their overall surface can be more porous than other materials. Their surface quality allows them to absorb lubricants, enabling manufacturers to obtain self-lubricating bearings.

High performance. Powdered metals can be combined with other materials, allowing them to produce bearings that perform well in different environments. Their microstructure can also be precisely controlled, which allows them to perform better when used in specific temperature ranges.

Guaranteed cost effectiveness. Powdered metals not only provide bearings with excellent surfaces, superior porosity and high performance, but they also provide reliable cost benefits to the users of the bearings.

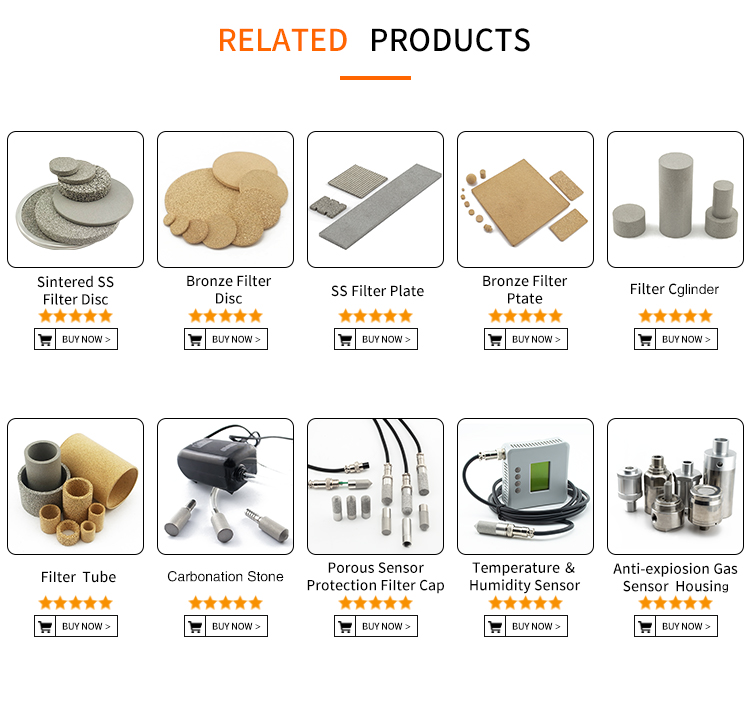

Sintered metal filters are highly efficient products in which particles are collected on the media surface. Proper selection of filter pore size must balance the filtration application's need for particle retention, pressure drop, and backwash capability. Three process factors are to consider: fluid velocity through the filter media, fluid viscosity, and particle characteristics. The critical particle characteristics are particle shape, size, and density. The results in a hard, conventional, or unconventionally shaped sintered filter with a non-compressible disc or cup and other shapes.

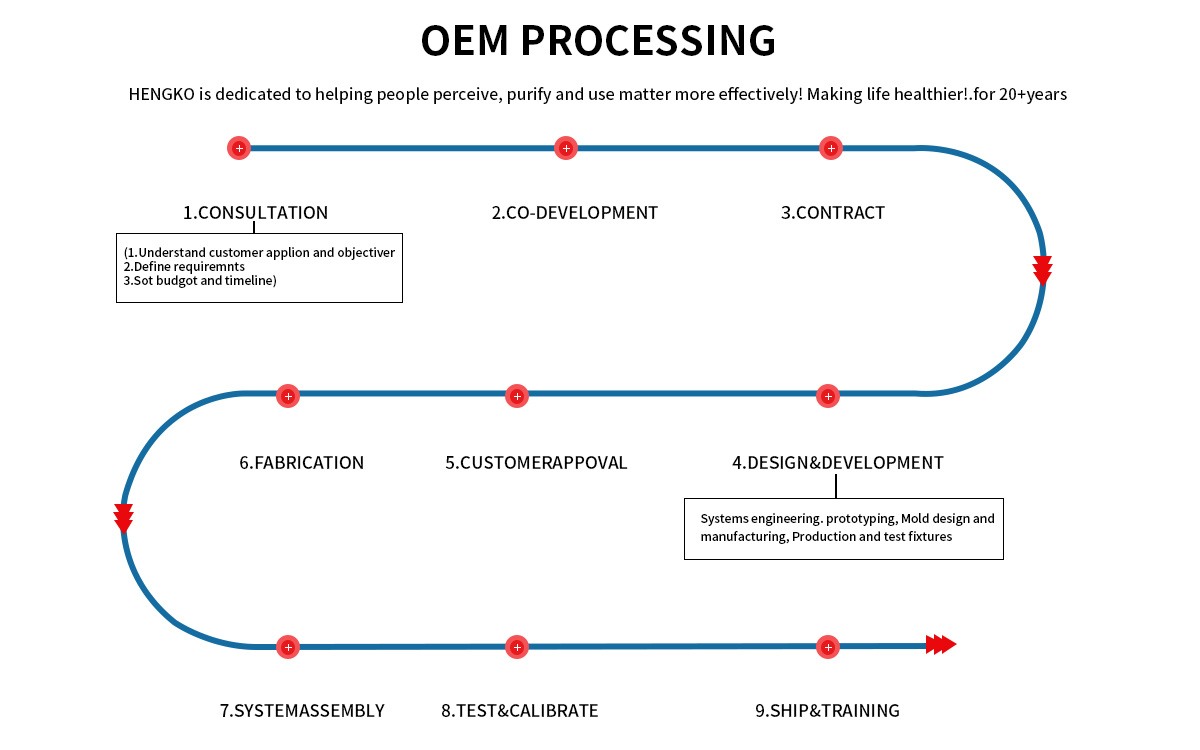

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!