Temperature and Humidity Sensor for Semiconductor Clean Room Temperature Humidity Control Scheme

Product Show

The temperature and humidity of clean space are mainly determined according to the process requirements, but under the condition of meeting the process requirements, the sense of comfort should be taken into account. With the improvement of air cleanliness requirements, there has been a trend of more and more strict requirements for temperature and humidity.

As the processing accuracy is finer and finer, so the temperature fluctuation range is less and less. For example, in the lithographic exposure process of large-scale integrated circuit production, the difference in thermal expansion coefficient between glass and a silicon wafer as a mask material is required to be smaller and smaller. Diameter 100 um silicon wafer, the temperature rise of 1 degree, will cause 0.24um linear expansion, so there must be a temperature of ±0.1 degree, at the same time the humidity value is generally low because people sweat, the product will have pollution, especially afraid of sodium semiconductor workshop, this workshop should not exceed 25 degrees.

High humidity causes more problems. When relative humidity exceeds 55%, dew will form on the wall of the cooling water pipe, which will cause various accidents if it happens in precision devices or circuits. When the relative humidity is 50%, it is easy to rust. In addition, when the humidity is too high, the dust stuck to the surface of the silicon chip will be chemically adsorbed on the surface to resist removal. The higher the relative humidity is, the more adhesion is difficult to remove, but when the relative humidity is lower than 30%, the particles are easy to adsorb on the surface due to the action of electrostatic force, and a large number of semiconductor devices are prone to breakdown. The optimum temperature range for wafer production is 35-45%.

Therefore, the control of temperature and humidity is particularly important, HENGKO can provide you with a series of temperature and humidity transmitter customized processing solutions!

Temperature and Humidity Sensor for Semiconductor Clean Room Temperature Humidity Control Scheme

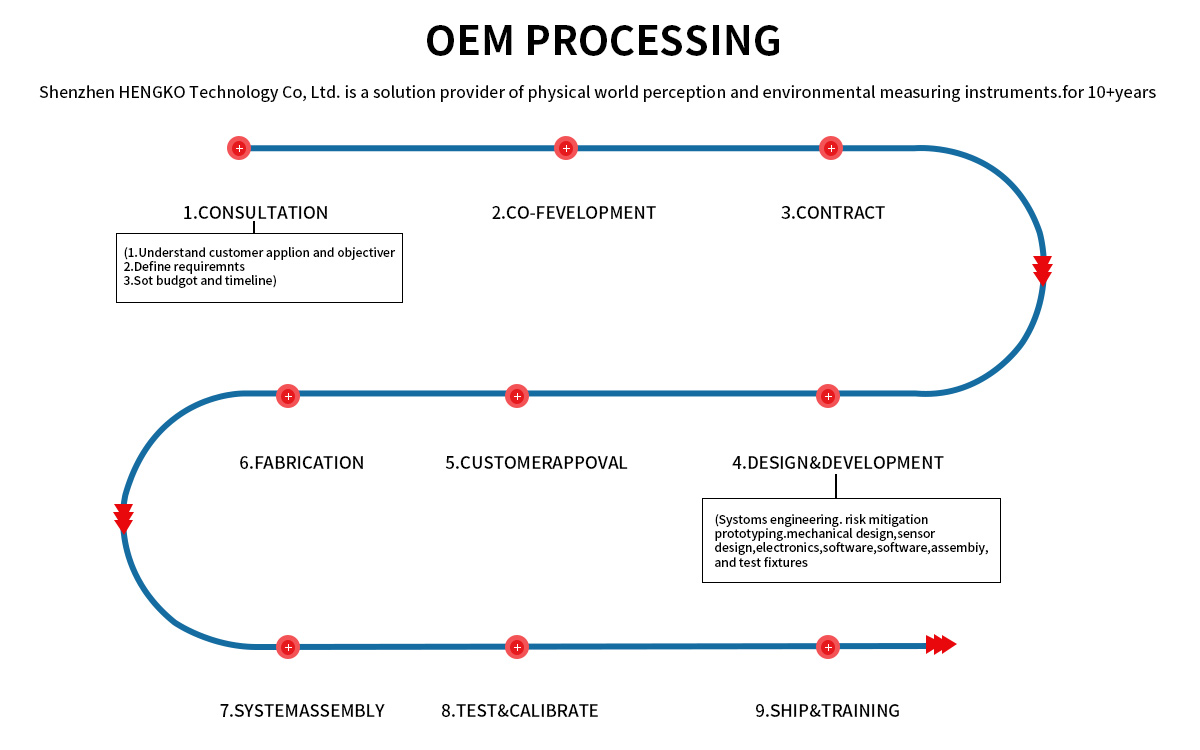

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!