CEMS Flue Gas Online Monitoring with Microporous Sintered Filter

Flue gas monitoring stainless steel microporous sintered filter element

Flue gas monitoring stainless steel microporous sintered filter element

Sintered filter element filter tube for cems flue gas online monitoring and purification system

The microporous stainless steel powder sintered filter tube for small molecule filtration is made of stainless steel powder pressed through a mold, sintered at high temperature, and integrally formed. It has the advantages of high mechanical strength, high-temperature resistance, good corrosion resistance, uniform pore size distribution, good air permeability, cleanable regeneration, and welding machine machining. Adjusting the powder particle size and process conditions makes it possible to produce porous metal sintered filter elements with a wide range of filtration accuracy. Due to the many advantages of porous metal powder sintered materials, this type of product is widely used in catalyst recovery, gas-liquid Filtration, and separation in the fields of the chemical industry, medicine, beverage, food, metallurgy, petroleum, environmental protection fermentation; various gases, Dust removal, sterilization, and oil mist removal of steam; noise reduction, flame arresting, gas buffering, etc.

Features:

Features:

1. Stable shape, impact resistance, and alternating load capacity is better than other metal filter materials;

2. Air permeability, stable separation effect;

3. Excellent loading and unloading strength, suitable for use in high temperature, high pressure, and strong corrosive environments;

4. Especially suitable for high-temperature gas filtration;

5. Products of various shapes and precision can be customized according to user requirements, and various interfaces can be used by welding.

Performance: acid resistance, alkali resistance, high-temperature resistance, low-temperature resistance, fire prevention, anti-static

Working environment: Nitric acid, sulfuric acid, acetic acid, oxalic acid, phosphoric acid, 5% hydrochloric acid, molten sodium, liquid hydrogen, liquid nitrogen, hydrogen sulfide, acetylene, water vapor, hydrogen, gas, carbon dioxide gas, and other environments. It has a variety of porosity (28%-50%), pore size (0.2um-200um), and filtration accuracy (0.2um-100um), with criss-cross channels, high-temperature resistance, and rapid cooling and heat resistance. Anti-corrosion. It is suitable for various corrosive media such as acids and alkalis. The stainless steel filter element can resist general acid-base and organic corrosion, which is especially suitable for filtering sulfur-containing gases. It has high strength and good toughness. It is suitable for high-pressure environments. It can be welded. Easy to load and unload. Stable pore shape and uniform distribution ensure stable filtration performance. Good regeneration performance. After repeated cleaning and regeneration, the filtration performance recovers by over 90%.

Operating temperature: ≤900°C

Wall thickness: generally 3mm

Internal pressure: 3mpa

Material: 304, 304L, 316, 316L.

Dust particle separation, purification, and Filtration Stainless steel powder sintered filter element have beneficial properties such as corrosion resistance, high-temperature resistance, high strength, easy assurance of filtration accuracy, and easy regeneration. The titanium filter element is made of titanium powder after molding and high-temperature sintering, so the surface particles are not easy to fall off; the use in the air can reach 500-600°C; it is suitable for filtering various corrosive media, such as hydrochloric acid, sulfuric acid, Filtration of hydroxide, seawater, aqua regia and chloride solutions such as iron, copper, and sodium. It has excellent mechanical properties, can be machined for cutting, welding, etc., has high compressive strength, and its filtration accuracy is easy to ensure. The pore diameter will not be deformed even if it works under high temperatures and pressure. Its porosity can reach 35-45%, the pore size distribution is uniform and the dirt holding capacity is large, and the regeneration method is simple and can be reused after regeneration.

Dust particle separation, purification, and Filtration stainless steel powder sintered filter element have excellent performance. It can be widely used in the fields of the pharmaceutical industry, water treatment industry, food industry, biological engineering, chemical industry, petrochemical industry, metallurgical industry, and gas purification. It is a new material with broad development prospects.

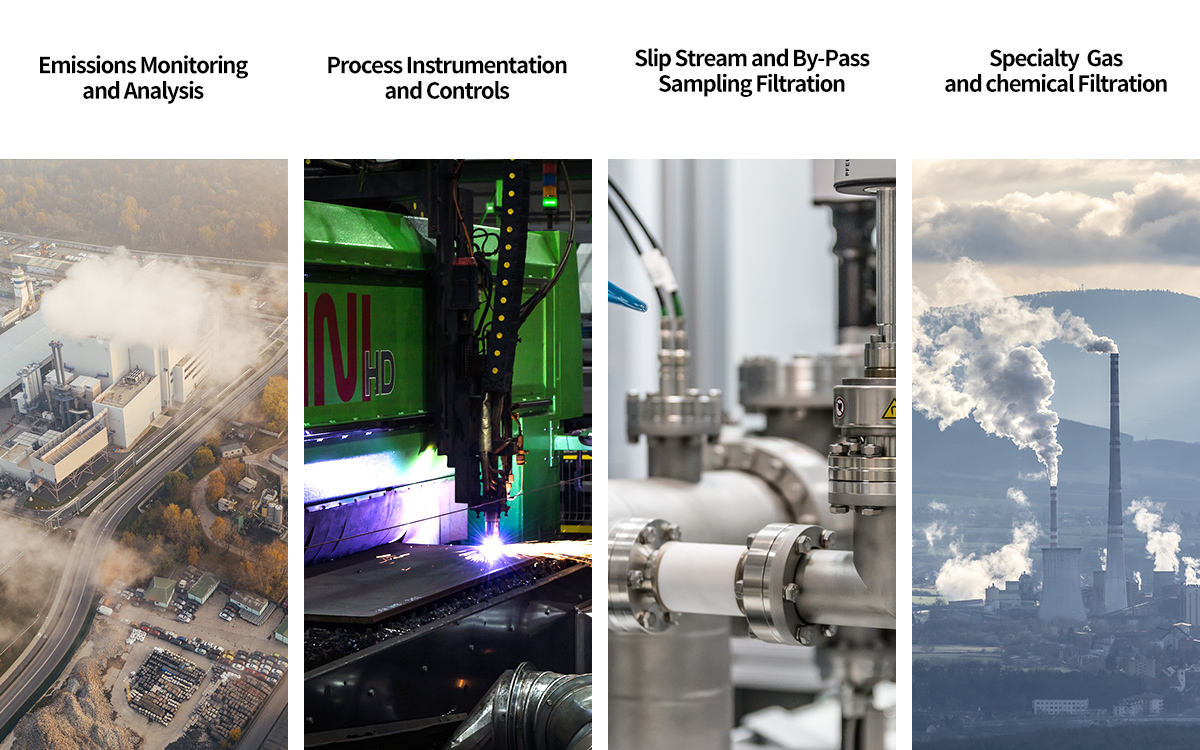

Typical uses include:

1. In the pharmaceutical industry, it is used for decarbonization filtration in the concentrated preparation process of large infusion solutions, small injections, eye drops, and oral liquids and for ensuring safety before terminal Filtration in the diluted preparation process.

2. Impurity removal and Filtration in the production process of raw materials, decarbonization filtration, and fine Filtration of materials.

3. Safe Filtration for ultrafiltration, RO, and EDI systems in the water treatment industry, Filtration after ozone sterilization, and ozone aeration.

4. Clarification and Filtration of beverages, liquor, beer, vegetable oil, mineral water, soy sauce, and vinegar in food and beverage.

5. Decarbonization filtration and precision filtration of liquid products, liquid raw materials, and pharmaceutical intermediates in the chemical industry, Filtration and recovery of ultra-fine particles and catalysts, precision filtration after resin adsorption, and impurity removal and Filtration of system heat transfer oil and materials, catalysis Gas purification, etc.

6. Oilfield return water filtration and seawater desalination field before reverse osmosis to ensure safety filtration.

7. High-temperature decarbonization and white clay filtration in the dye industry.

8. In terms of gas purification, it mainly includes purification and Filtration of steam, compressed air, and catalytic gas.

FAQ

1. What is a high purity semiconductor gas filter?

A high purity semiconductor gas filter is a special type of filter designed to remove impurities from gases used in the manufacturing of electronic components. These filters are made from materials that can withstand high temperatures and corrosive chemicals, and are designed to remove particles down to the nano-scale level.

2. Why are high purity semiconductor gas filters important?

In the production of semiconductors, even small amounts of impurities can cause defects and reduce the overall quality of the final product. High purity semiconductor gas filters help ensure that the gases used in manufacturing processes are free from contaminants, resulting in higher quality electronic components.

3. What types of gases can be filtered with high purity semiconductor gas filters?

High purity semiconductor gas filters can be used to filter a wide range of gases, including hydrogen, nitrogen, oxygen, and a variety of other process gases. Depending on the specific manufacturing process, different types of filters may be required to achieve the desired level of purity.

4. How are high purity semiconductor gas filters made?

High purity semiconductor gas filters are made from materials such as stainless steel, and other high-strength metals. The filter elements are typically very small, with pore sizes ranging from 0.1 to 1 micron. The filters are often coated with special materials to enhance their surface properties and improve their filtration performance.

5. How long do high purity semiconductor gas filters last?

The lifespan of a high purity semiconductor gas filter can vary depending on a number of factors, including the type of filter, the gas being filtered, and the specific manufacturing process. In general, these filters are designed for long-term use and can last for several months or even years before needing to be replaced. Regular maintenance and cleaning can help prolong the lifespan of these filters and ensure optimal performance over time.