-

wide mouth jar mason jar with stainless steel sintered filter disc for high temperature...

Small changes, big benefits! We store bentonite clay inside the jar and bake it in a vacuum oven to remove moisture. Even with the lid on the clay gets out o...

View Detail -

Monocrystalline silicon pressure transmitter sintered metal porous filter disc

Using single crystal silicon piezoresistive technology pressure sensor, process industry liquid level measurement applications sintered filter disc material:...

View Detail -

Sintered Porous Metal Leaf Disc Filter For the Polymer Melt Industry

Leaf Disc and Solid Plate Filters for critical hot melt polymer filtration applications. Leaf disc and solid plate filters are designed for critical h...

View Detail -

Sintered porous metal filter disc 20 micron for Gas purification and analysis

Achieve Unparalleled Gas/Solids Separation with HENGKO's Sintered Stainless Steel Filter Discs! Our filtration systems, featuring sintered stainless ...

View Detail -

HENGKO porous metal disc test filter for Laboratory bench scale testing

Perfect for: - Laboratory bench scale testing -Feasibility studies -Smallscale, batch-type processes HENGKO's designs and produces bench-top filter, our po...

View Detail -

Porous Metal Filter Sintered Stainless Steel Disc Filter for Fiberf Yarn Production / P...

Porous Metal Filters HENGKO's porous metal filter design provides increased life and performance to polymer spin pack filtration. The filter is a sintered,...

View Detail -

47mm Porous Disc Filter 316L SS Sintered Metal Filter for Laboratory Bench Scale Testing

HENGKO’s bench-top filter (47mm disc test filter), our 47mm disc filter, is a simple, inexpensive way to effect liquid-solid and gas-solid separations with e...

View Detail -

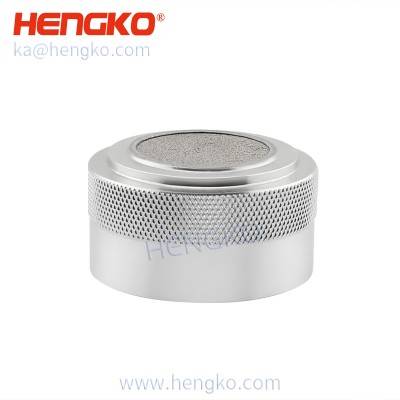

4-20mA Infrared CH4 CO2 gas sensor ( carbon dioxide sensor ) detector aluminum alloy ho...

Stainless steel housing with tamperproof protection. For use with separately certified, industry-standard junction boxes or OEM gas detector enclosures. ...

View Detail -

Fireproofing and anti-explosion sintered housing with sintered filter disc for fixed ga...

Explosion-proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter-bonded flame arrestor provides the gas diffusion...

View Detail -

Custom Gas Sensor protective covers with sintered powder metal stainless steel filter disc

Explosion proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter bonded flame arrestor provides the gas diffusion...

View Detail -

Stainless steel flame arrestors sensing element protection housing for carbon monoxide ...

Explosion-proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter-bonded flame arrestor provides the gas diffusion...

View Detail -

sintered stainless steel 316L metal porous gas sensor alarm waterproof enclosure + sint...

Explosion-proof sensor assemblies are made of 316 stainless steel for maximum corrosion protection. A sinter-bonded flame arrestor provides the gas diffusion...

View Detail -

waterproof porous stainless steel explosion-proof gas sensor probe protective covers wi...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Micron Sintered Porous sintered stainless steel 316L metal porous gas sensor alarm expl...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Analog carbon dioxide co2 fixed gas detector sintered stainless steel probe with IP66 h...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Custom gas detector component-Explosion proof Stainless Steel Probe Filter Caps Protect...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Sintered Stainless Steel 316L/316 Filter Disc Used For Gas Leakage Detectors Protection...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Custom sintered stainless steel round disc filter for flameproof and fire resistance

Sintered metal materials are a popular choice because these highly engineered materials consist of a uniform, interconnected porosity that can be fabricated ...

View Detail -

Sintered Stainless Steel Sanitary Tri Clamp Filter Disc with Viton O-Ring frit Gasket f...

At HENGKO® we try to help our customers build high-quality, safe, and precise operations for processing hemp. The best CBD extracts equipment that we’re...

View Detail -

In-Line Porous Metal Sintered Filter Disc Strainers Filter Manufacturer -HENGKO

HENGKO manufactures spare washers for Venus, Kitty, Class, and Musa Moka pots. The package includes a washer and a coffee filter plate. Gasket diameterPlease...

View Detail

Main Application of Sintered Metal Discs

some applications of sintered metal discs:

* Filtration:

Sintered metal discs are widely used in filtration applications because of their precise pore sizes, good permeability, and high strength. They can be used to filter a variety of substances, including liquids, gases, and even molten metals. For example, they are used in filtering beverages, pharmaceuticals, chemicals, and air and water in various industries . They can be customized to have different pore sizes, depending on the specific filtration application.

* Fluidization :

Sintered metal discs are used in fluidized bed systems, which are used in a variety of industrial processes, such as drying, classification, and coating. In a fluidized bed system, a gas is passed through a bed of particles, causing the particles to behave like a fluid. Sintered metal discs are used to distribute the gas evenly throughout the bed and to prevent the particles from escaping.

* Heat Exchangers:

Sintered metal discs can be used as heat exchangers because of their high thermal conductivity and large surface area. Heat exchangers are used to transfer heat from one fluid to another. Sintered metal discs can be used in a variety of heat exchanger applications, such as air conditioning systems, radiators, and boilers.

* Friction Components:

Sintered metal discs are used in a variety of friction components, such as clutch plates and brake pads. Sintered metal discs can be made from a variety of materials, including iron, copper, and bronze. The specific material used will depend on the desired friction properties. For example, sintered iron discs are often used in clutch plates because they are strong and wear-resistant.

* Sound Dampening:

Sintered metal discs can be used to dampen sound. They can be used in a variety of applications, such as automotive engines, appliances, and industrial machinery. Sintered metal discs can absorb sound waves and reduce noise levels.

Main Features of Sintered Metal Discs

Sintered metal discs offer a unique combination of properties that make them valuable in various industrial applications. Here are some of their main features:

1. High Porosity and Permeability:

-

Sintered metal discs are created from metal powder compressed and then heated to a high temperature below the melting point, causing the particles to bond together. This process creates a network of interconnected pores throughout the disc, allowing fluids or gases to pass through while capturing particles larger than the pore size.

-

The porosity of the disc can be precisely controlled during the manufacturing process, enabling customization for specific filtration requirements. This allows for efficient separation of desired materials from unwanted contaminants.

2. Superior Strength and Durability:

-

Despite their porous nature, sintered metal discs exhibit remarkable strength and durability. The bonding between the metal particles creates a robust structure that can withstand high pressures and mechanical stresses.

-

This makes them suitable for demanding applications in harsh environments, such as filtering corrosive liquids or operating under high pressure.

3. Excellent Temperature Resistance:

-

The materials used in sintered metal discs, such as stainless steel or bronze, are inherently resistant to high temperatures. They can function effectively in hot environments without compromising their structural integrity or filtration performance.

-

This characteristic makes them ideal for applications involving hot fluids, gases, or molten metals.

4. Corrosion and Wear Resistance:

-

The materials used in sintered metal discs often exhibit excellent resistance to corrosion and wear. This is particularly true for stainless steel discs, which can withstand exposure to harsh chemicals and abrasive environments.

-

This resistance to corrosion and wear ensures a long service life for the discs, minimizing the need for frequent replacements.

5. Reusability and Cleanability:

-

Sintered metal discs are reusable, offering a cost-effective and environmentally friendly advantage. They can be easily cleaned and backwashed, allowing for repeated use in filtration applications.

-

This reusability reduces waste and maintenance costs compared to disposable filter media.

6. Versatility and Customization:

-

Sintered metal discs can be manufactured in various shapes, sizes, and pore sizes to meet the specific needs of different applications. They can also be fabricated from various materials, each offering unique properties for specific filtration requirements.

-

This versatility makes them a highly adaptable solution for a wide range of industrial filtration and separation processes.

FAQ

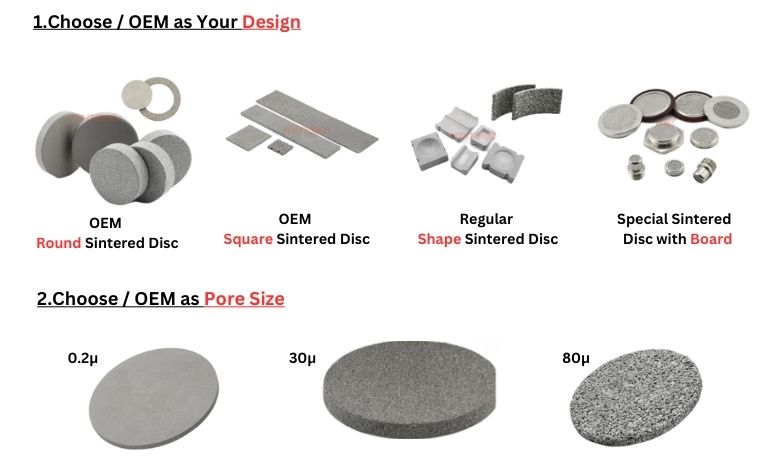

1. What are the different types of sintered metal disc filters?

Sintered metal disc filters can be categorized based on several factors:

* Material: Stainless steel is the most common material due to its excellent corrosion resistance, strength,

and wide operating temperature range. Other materials include bronze, nickel, and even exotic materials

like Hastelloy for highly corrosive environments.

* Porosity and pore size: The porosity refers to the percentage of void space in the filter, while pore size

determines the smallest particle the filter can capture. Filters are available in a wide range of porosities

and pore sizes, from microns to millimeters, to suit different filtration needs.

* Number of layers: Single-layer discs offer high flow rates but limited dirt-holding capacity. Multi-layer

discs have graded pore sizes, offering finer filtration and higher dirt-holding capacity while maintaining

acceptable flow rates.

* Shape: Although discs are the most common shape, filters can also be custom-made in various shapes

like squares, rectangles, cylinders, or even specific geometric shapes for specific applications.

2. What are the advantages and disadvantages of using sintered metal disc filters?

Advantages:

* High strength and durability: They can withstand high pressures, temperatures, and harsh environments.

* Precise and consistent filtration: Consistent pore sizes ensure reliable separation of desired materials from unwanted contaminants.

* Versatility: Available in various materials, porosities, pore sizes, and shapes to meet diverse application needs.

* Reusability and cleanability: They can be easily cleaned and reused, reducing waste and maintenance costs.

* High thermal conductivity: Suitable for applications involving heat transfer.

Disadvantages:

* Higher initial cost compared to some disposable filters.

* Can clog with very fine particles, requiring regular cleaning or backwashing.

* Not suitable for highly viscous liquids due to potential flow rate limitations.

3. How do I choose the right sintered metal disc filter for my application?

Selecting the appropriate filter requires considering several factors:

* Fluid properties: The type of fluid being filtered (liquid, gas, etc.) and its viscosity.

* Particle size and type: The size and characteristics of the particles you want to capture.

* Desired flow rate: The required rate of fluid flow through the filter.

* Operating pressure and temperature: The pressure and temperature the filter will encounter during operation.

* Chemical compatibility: The compatibility of the filter material with the fluids being filtered.

* Budget and reusability requirements: Initial cost vs. long-term cost savings through reusability.

Consulting with a filtration specialist or the filter manufacturer is recommended to ensure you choose the optimal sintered metal disc filter for your specific application.

4. How do I clean and maintain sintered metal disc filters?

The cleaning method depends on the type of filter, the contaminants being filtered, and the manufacturer's recommendations. Common cleaning methods include:

* Backwashing: Forcing clean fluid through the filter in the reverse direction to dislodge trapped particles.

* Ultrasonic cleaning: Using sound waves to dislodge particles from the filter pores.

* Chemical cleaning: Using specific cleaning solutions compatible with the filter material and safe for the intended use of the filtered product.

It is crucial to follow the manufacturer's instructions for proper cleaning and maintenance to ensure optimal performance and longevity of the sintered metal disc filter.

5. Where can I find more information about sintered metal disc filters?

Several resources are available to learn more about sintered metal disc filters:

* Filter manufacturer websites: Most manufacturers provide detailed information about their products, including specifications, application guides, and technical resources.

* Industry publications and websites: Trade publications and websites focused on filtration technology often contain articles and resources discussing various filter types, including sintered metal discs.

* Engineering and filtration associations: Professional organizations like the American Filtration & Separations Society (AFSS) offer educational resources and information about different filtration technologies.

By considering these FAQs and seeking further information, you can make an informed decision about whether sintered metal disc filters are the right solution for your filtration needs.

CONTACT US

Unlock the potential of your devices with custom OEM sintered metal discs from HENGKO.

Email us today at ka@hengko.com to explore our advanced manufacturing capabilities and

take the first step towards superior performance and quality.

Let's create something exceptional together. Contact us now!