Sintered 5 10 40 100 microns porous 316L stainless steel filter wire mesh for dust filter

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration cooling under extremity high temperatures, airflow control distribution, enhancement of heat and mass transfer, noise reduction, current limitation, etc.

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration cooling under extremity high temperatures, airflow control distribution, enhancement of heat and mass transfer, noise reduction, current limitation, etc.

Features:

High strength and durability since high temperature sintering

Anti-corrosion and heat resistance up to 600°C

Steady filter rating from 1 micron to 8000 microns

Widely used for uniform filtration in high pressure or high viscosity environment

Want more information or would like to receive a quote?

Click the Online Service button at the top right to contact our salespeople.

Sintered 5 10 40 100 microns porous 316L stainless steel filter wire mesh for dust filter

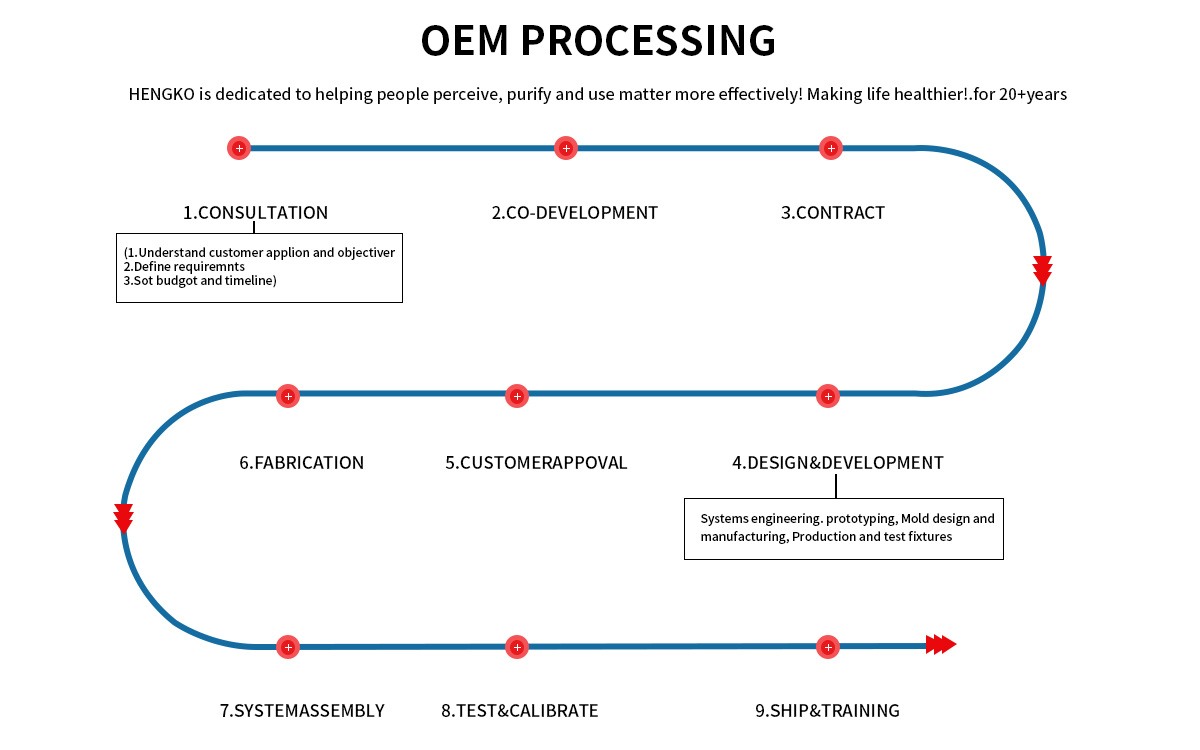

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

]15~QML.png)

]15~QML.png)