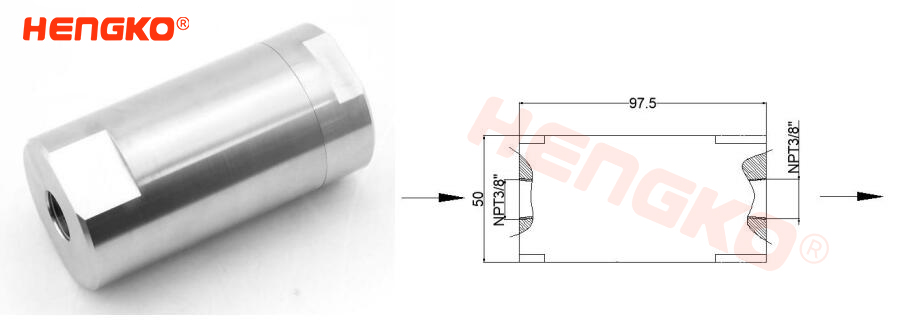

HENGKO® High Purity Semiconductor Gas Filter

High purity series filters are designed to filter semiconductor gases. This fully welded assembly will deliver 0.003 micron particle assisted retention.

High purity series filters are designed to filter semiconductor gases. This fully welded assembly will deliver 0.003 micron particle assisted retention.

Semiconductor gas filters feature internal all stainless steel construction including stainless steel sintered filter cartridge and support structure, 316L stainless steel electropolished welded housing for critical semiconductor process gas applications.

Purge the final assembly with filtered nickel to achieve initial cleanliness.

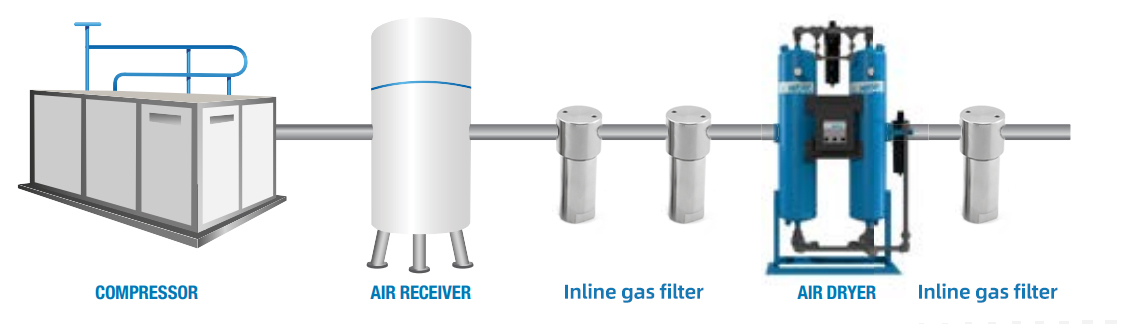

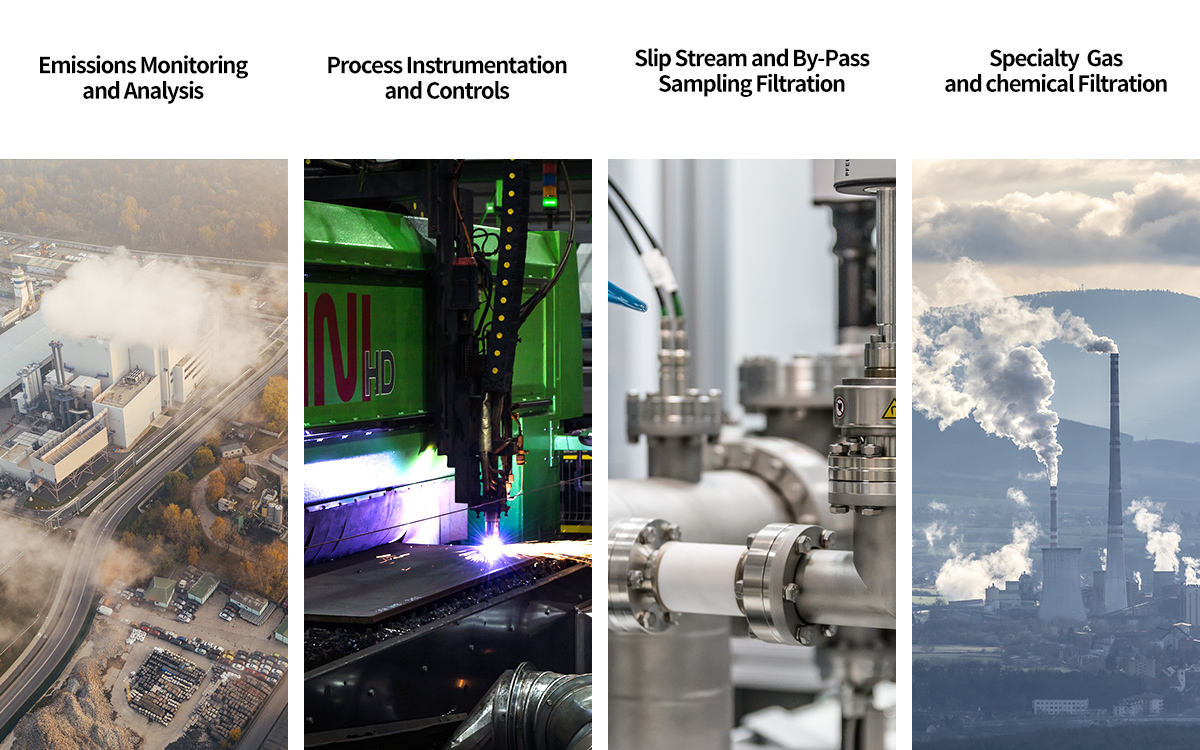

Application Industries:

Point-of-use semiconductor special gas filtration

Inert and special gas transfer.

Technical specifications are as follows:

3nm filter rating

Our porous sintered stainless steel filters provide effective particle retention efficiency at 0.003μm.

Maximum operating temperature: 121°C (250°F)

Maximum operating pressure: 207 bar (3000 psig) at 20°C (68°F).

Features and Benefits:

Porous stainless steel sintered filter media / Porous stainless steel sintered support structure

316L sintered stainless steel filters provide superior flow resistance and chemical resistance.

Electropolished 316L housing

This filter assembly has a 10Ra electropolished 316L stainless steel housing to prevent corrosion and particle formation.

Cleanroom Production

Our stainless steel sintered filters for semiconductor gases are manufactured in a clean room to ensure particle-free, chemically clean, non-organic handling and bagging, providing a high level of out-of-bag cleanliness. Additional pretreatment is optional.

FAQ

1. What is a high purity semiconductor gas filter?

A high purity semiconductor gas filter is a special type of filter designed to remove impurities from gases used in the manufacturing of electronic components. These filters are made from materials that can withstand high temperatures and corrosive chemicals, and are designed to remove particles down to the nano-scale level.

2. Why are high purity semiconductor gas filters important?

In the production of semiconductors, even small amounts of impurities can cause defects and reduce the overall quality of the final product. High purity semiconductor gas filters help ensure that the gases used in manufacturing processes are free from contaminants, resulting in higher quality electronic components.

3. What types of gases can be filtered with high purity semiconductor gas filters?

High purity semiconductor gas filters can be used to filter a wide range of gases, including hydrogen, nitrogen, oxygen, and a variety of other process gases. Depending on the specific manufacturing process, different types of filters may be required to achieve the desired level of purity.

4. How are high purity semiconductor gas filters made?

High purity semiconductor gas filters are made from materials such as stainless steel, and other high-strength metals. The filter elements are typically very small, with pore sizes ranging from 0.1 to 1 micron. The filters are often coated with special materials to enhance their surface properties and improve their filtration performance.

5. How long do high purity semiconductor gas filters last?

The lifespan of a high purity semiconductor gas filter can vary depending on a number of factors, including the type of filter, the gas being filtered, and the specific manufacturing process. In general, these filters are designed for long-term use and can last for several months or even years before needing to be replaced. Regular maintenance and cleaning can help prolong the lifespan of these filters and ensure optimal performance over time.