-

Sintered micron stainless steel porous metal filter cylinder for gas filtration

Product Describe Sintered Metal Filter Cartridges: Porous metal filters have a wide variety of industrial filter uses. These reusable, high-quality filters a...

View Detail -

Sintered porous metal filter disc 20 micron for Gas purification and analysis

Achieve Unparalleled Gas/Solids Separation with HENGKO's Sintered Stainless Steel Filter Discs! Our filtration systems, featuring sintered stainless ...

View Detail -

316 Micron Stainless Steel Air Aerator Stone Diffusion Stone Used in Microalgae Photosy...

Product Describe Bioreactors are ‘walls’ of water-filled clear tubes that allow photosynthesis, where microalgae grow with the addition of carbon dioxide. In...

View Detail -

Wholesale Wire Mesh Filter Stainless Steel 10 Micron Sintered Tube For Pharmaceutical M...

Stainless steel filters are ideal for use in demanding engineering specifications that require filtration in adverse environmental conditions, such as jet en...

View Detail -

20 Micron 316 Stainless Steel Wire Mesh Filter Cartridge Inner Core 32mm Length M4 Thread

Wire mesh filter is wire mesh that is stretched by use of metal threads, with fine openings between the different metal threads. When polluted water is pump...

View Detail -

Craft beer brewing kit sintered 316 stainless steel 2 micron micro bubble air oxygenati...

HENGKO POROUS SPARGER is ROSH and FDA certificate of safety and environmental protection and can be used in food applications of sintered stainless steel air...

View Detail -

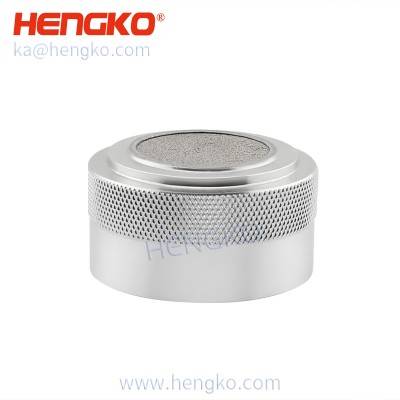

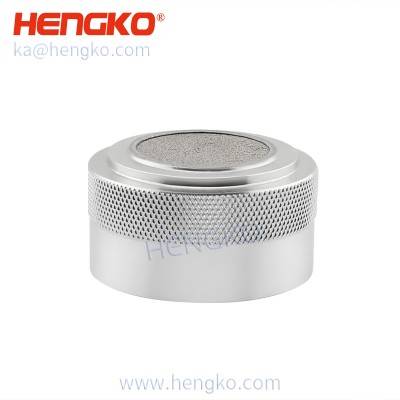

HK66MBN stainless steel porous humidity sensor housing – stainless steel sintered...

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

HK66MEN temperature and humidity sensors protection cover casing, Micron porous stainle...

HENGKO temperature and humidity probe consist of high precision RHTx series sensor module, one meter 4-pin cable, sintered metal filter cap, cable gland, etc...

View Detail -

Manufacture HSY4MCN micron stainless steel 316L temperature and humidity sensor probe h...

HENGKO stainless steel sensor shell are made by sintering 316L powder material in high temperature. They have been widely used in environmental protection, p...

View Detail -

HK98G3/8U 20 Micron porous sintered waterproof anti-dust stainless steel temperature an...

HENGKO stainless steel sensor shells are made by sintering 316L powder material at high temperatures. They have been widely used in environmental protection,...

View Detail -

IP67 waterproof stainless steel 316 micron porous sintered temperature humidity sensor ...

HENGKO wifi digital temperature and humidity module adopt high precision RHT series sensor equipped with a sintered metal filter shell for large air permeabi...

View Detail -

HENGKO micron small bubble air sparger oxygenation carbanation stone used in acrylic wa...

Product Describe HENGKO air sparger bubble stone is stainless steel 316/316L, food grade, with a beautiful appearance, suitable for hotels, fine dining and o...

View Detail -

2 Microns Diffusion Stone for Alkaline Water Purifier Health Ionizer Energy

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Hydrogen rich water machine – sintered SS 316L stainless steel 0.5 2 micron air o...

Hydrogen water is clean, powerful, and with hydron. It helps to purify the blood and gets blood moving. It can prevent many kinds of diseases and improve peo...

View Detail -

Micron Sintered Porous sintered stainless steel 316L metal porous gas sensor alarm expl...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

316L flame-proof filter housing co2 semiconductor microns modbus sensor filter probe ho...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

Fireproofing and anti-explosion 5 10 20 microns sintered metal gas sensor explosion pro...

HENGKO explosion-proof sensor housing is made of 316L stainless steel and aluminum for maximum corrosion protection. A sinter-bonded flame arrestor provides ...

View Detail -

stainless steel 316 sintered metal filter 30-90 microns filter element – space al...

Product Describe HENGKO stainless steel filter elements are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatur...

View Detail -

Microns porous stainless steel sintered filters inline reusable washable fuel filter

Captures dirt and grit as small as 40 microns before they can cause damage to the intake system. CNC polished alloy body with the sintered metal internal ele...

View Detail -

custom 5 60 micron gas pressure flow meter 316L metal stainless steel sintered porous f...

_<img src="/uploads/HTB1WxA_aUvrK1RjSspc762zSXXaK.png" width="750" height="980" usemap="#HENGKO" bord...

View Detail

Why use Stainless Steel Micron Filter ?

Actually There are several reasons why stainless steel micron filters are popular choices for a variety of industry applications:

* Durability: Stainless steel is a strong and durable material that can withstand high pressure and temperatures. This makes them ideal for use in harsh environments or for applications where the filter will be under a lot of stress.

* Corrosion resistance: Stainless steel is resistant to corrosion from most chemicals, making them suitable for use with a wide range of fluids. This is important because some filters can corrode and release particles into the fluid being filtered.

* Reusable: Unlike some other types of filters, stainless steel micron filters can be cleaned and reused multiple times. This can save money in the long run, as you won't need to replace the filter as often.

* High flow rates: Stainless steel micron filters can often achieve high flow rates, even with very fine filtration ratings. This is important in applications where it is necessary to filter a large volume of fluid quickly.

* Versatility: Stainless steel micron filters are available in a wide range of micron ratings, making them suitable for a variety of filtration applications. They can be used to filter out particles of all sizes, from large sand particles down to very small bacteria.

Here are some examples of applications where stainless steel micron filters are commonly used:

* Chemical processing

* Food and beverage processing

* Water treatment

* Oil and gas production

* Pharmaceutical manufacturing

Types of Sintered Stainless Steel Micron Filter ?

Sintered stainless steel micron filters come in various forms, each suited for specific applications based on their unique properties and configurations. Here are the main types:

1. Sintered Mesh Filters:

* Description: These filters consist of multiple layers of fine metal powder sintered together to form a rigid, porous structure. They offer high strength, excellent filtration efficiency, and are relatively easy to clean.

* Applications: Commonly used in general filtration applications like chemical processing, food and beverage clarification, and water pre-filtration due to their versatility and affordability.

2. Dutch Weave Mesh Filters:

* Description: A specific type of sintered mesh filter known for its superior strength and durability due to its unique interlocking weave pattern. They can withstand high pressure and harsh chemicals.

* Applications: Particularly suited for demanding environments in chemical processing, oil and gas production, and other applications requiring exceptional strength and chemical resistance.

3. Sintered Disc Filters:

* Description: These are flat, disc-shaped filters ideal for applications requiring high flow rates and minimal pressure drop. They offer excellent filtration efficiency and can be easily integrated into filter housings.

* Applications: Widely used in water treatment, pharmaceutical manufacturing, and various other industries requiring efficient and compact filtration solutions.

4. Sintered Cartridge Filters:

* Description: Self-contained units consisting of a sintered metal element housed within a cartridge body. They are readily replaceable and available in various micron ratings and sizes.

* Applications: Popular choice for applications requiring easy installation, replacement, and maintenance, such as food and beverage processing, chemical filtration, and pre-filtration in various industries.

5. Sintered Candle Filters:

* Description: Cylindrical filters with a hollow core, offering a large filtration area and high dirt-holding capacity. They are suitable for applications with high flow rates and continuous filtration requirements.

* Applications: Primarily used in industrial filtration processes like wastewater treatment, oil and gas production, and chemical processing where large volumes of fluids need continuous filtration.

The choice of the most suitable sintered stainless steel micron filter depends on various factors like the desired filtration rating, pressure requirements, flow rates, application environment, and desired features like cleanability and reusability.

Main Application of Sintered Stainless Steel Micron Filter ?

The main applications of sintered stainless steel micron filters encompass a wide range due to their advantageous properties like durability, excellent filtration capabilities, reusability, and compatibility with various environments. Here are some key application areas:

1. Chemical Processing:

* Filtration of process fluids: Sintered filters effectively remove unwanted particles, catalysts, and other impurities from various chemical solutions. This not only protects equipment from wear and tear but also ensures product quality and prevents contamination in sensitive chemical processes.

* Catalyst Recovery: These filters are crucial for recovering valuable catalysts used in chemical reactions. Their precise micron rating allows them to capture the catalyst particles while allowing the desired product to pass through.

2. Food and Beverage Processing:

* Clarification and filtration of liquids: Sintered filters play a vital role in purifying liquids like wine, beer, juice, and dairy products. They remove unwanted particles like yeast, sediment, or bacteria, contributing to improved product clarity, taste, and shelf life.

* Air and gas filtration: In certain food and beverage applications, sintered filters are employed to remove contaminants and ensure clean air or gas for processes like fermentation or packaging.

3. Water Treatment:

* Pre-filtration and post-filtration: Sintered filters are often used in various stages of water treatment. They can act as pre-filters to remove large particles like sand and silt before further treatment stages. Additionally, they can be used as post-filters for final polishing or removing residual filtration media, ensuring clean and safe drinking water.

4. Oil and Gas Production:

* Filtration of fluids throughout the production process: From removing sand and debris in drilling fluids to filtering refined oil products, sintered filters are valuable components throughout the oil and gas production chain. They help protect equipment, improve product quality, and prevent contamination.

5. Pharmaceutical Manufacturing:

* Sterile filtration of pharmaceutical solutions and products: Sintered filters play a critical role in ensuring the sterility and purity of drugs and other pharmaceutical products. Their precise filtration removes bacteria, viruses, and other contaminants, adhering to strict safety and quality standards in pharmaceutical manufacturing.

6. Other Applications:

Beyond these prominent applications, sintered stainless steel micron filters find use in various other industries, including:

* Medical device manufacturing: Sterilizing and filtering fluids used in medical device production.

* Electronics industry: Protecting sensitive electronic components from dust and other contaminants.

* Environmental technology: Filtering air and wastewater in environmental remediation processes.

The versatility and adaptability of sintered stainless steel micron filters make them a valuable and reliable solution across a diverse range of applications demanding high-precision filtration and robust performance.

FAQ

1. What exactly is a sintered stainless steel micron filter?

A sintered stainless steel micron filter is a porous filtering component manufactured through a process called sintering. Here's how it works:

* Metal Powder: Fine stainless steel powder of a specific grade (commonly 304 or 316L) is selected.

* Molding: The powder is placed into a mold with the desired filter shape and compressed under high pressure.

* Sintering: The molded form (called a "green compact") is heated to a high temperature below the metal's melting point. This causes the metal particles to fuse, creating a solid, porous structure.

* Finishing: The filter may undergo additional treatments like cleaning, polishing, or integration into housing assemblies.

2. What are the primary advantages of using sintered stainless steel micron filters?

Sintered stainless steel micron filters offer several compelling benefits:

* Durability and Strength: Stainless steel's inherent properties translate into filters that can withstand harsh operating conditions, high pressures, and temperature variations.

* Corrosion Resistance: Their resistance to many chemicals and fluids makes them suitable for use in a broad range of applications.

* Precise Filtration: The sintering process allows for controlled pore sizes, enabling highly accurate and consistent filtration down to the micron level.

* Cleanability and Reusability: Sintered stainless steel filters can typically be cleaned with methods like backflushing and ultrasonic cleaning for extended use.

3. Where are sintered stainless steel micron filters commonly used?

The versatility of these filters makes them valuable components in various industries and applications:

* Chemical Processing: Filtration of process fluids, removal of contaminants, protection of downstream equipment.

* Food and Beverage: Ensuring product purity, clarity, and extended shelf life.

* Water Treatment: Removal of particulate matter for potable water and wastewater treatment.

* Pharmaceuticals: Filtration of active ingredients, excipients, and injectable solutions.

* Oil and Gas: Filtration of drilling fluids, produced water, and refined products.

4. How do I select the right sintered stainless steel micron filter for my application?

Choosing the appropriate filter requires considering several key factors:

* Filtration Rating: Determine the desired micron rating (pore size) needed to remove the target particles.

* Chemical Compatibility: Ensure the stainless steel grade is compatible with the fluids being filtered.

* Operating Conditions: Consider the pressure, temperature, and flow rate the filter must handle.

* Physical Requirements: Select the appropriate form factor (disc, cartridge, etc.) and connection types needed for your system.

5. How do I maintain and clean sintered stainless steel micron filters?

Proper maintenance ensures longevity and optimal performance:

* Regular Cleaning: Employ cleaning methods suitable for your application. These could include backwashing, ultrasonic cleaning, or chemical cleaning.

* Inspection: Check for signs of wear, damage, or clogging that might necessitate filter replacement.

Looking for a tailored Stainless Steel Micron Filter solution?

Reach out to HENGKO at ka@hengko.com for OEM services that meet your specific needs.

Let's create the perfect filtration solution together!