Corrosion resistant microns 316L stainless steel porous sintered filter metal sheets / plates for chemical industry, pharmaceutical industry

Product Describe

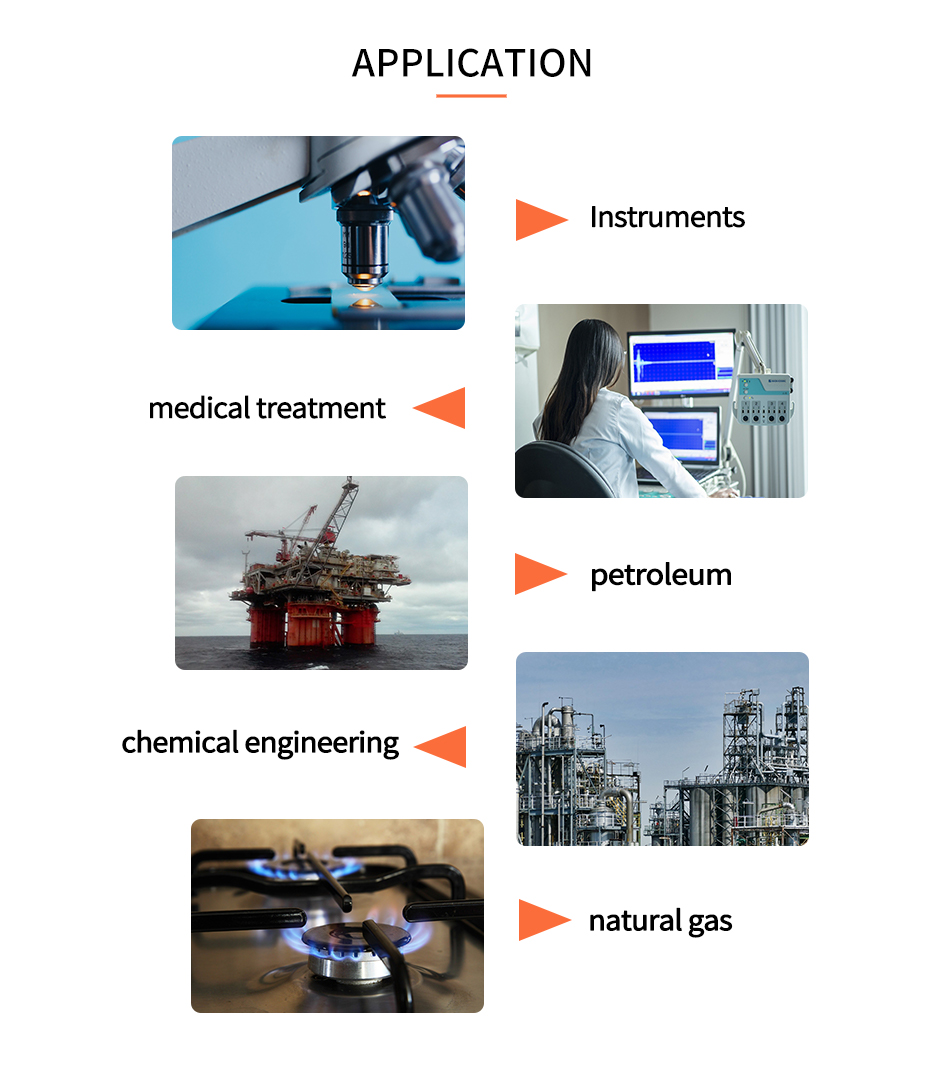

HENGKO porous metal gas diffusion layers are the leading choice for high performance electrolyzer and fuel cell applications. The uniform porosity, strength, and corrosion resistance provides superior performance over other di usion layer products. Mott substrates are available in a variety of alloys to support a full range of fuel cell operating temperatures, and can be coated with surface treatments or catalyst layers to enchance performance.

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for higher particle load filtration, where mere surface filters such as membranes do not provide enough life-time. With a thickness of 3 – 4 mm, more than 3000 times the size of a 1-micron particle, millions of microparticles can be trapped in every square meter of the filter area. Typically, filter sheets consist of a matrix of cellulosic or polymer fiber, enriched with minerals filter aids and held together with a resin binder.

Depth filter sheets are available in various grades for a wide variety of applications. The filter sheets show nominal retention rates from coarse (55 – 20 μm) to fine (15 – 1 μm) to sterile (0.6 – 0.04 μm). Therefore, they can be used for clarifying, fine and sterile filtration. They are available in all common sizes from 47 mm rounds up to 2.4 m × 1.2 m filter sheets. In between, practically all sizes are possible for all the different sheet filters available on the market.

During the filtration process, particles are slowed down within the filter sheet and eventually retained either mechanically by size or by electro-kinetic forces. Due to this effect, a long operating time can be reached before plugging and the depth filter sheets have a holding capacity of up to 4 l/m2.

FEATURES

» Uniform porosity for even distribution of gas ! ow

» Broad selection of corrosion resistant materials to support all operating temperatures

» Controllable porosity to provide the best balance of gas diffusion and water transport

» Low thickness variation to ensure full contact with mating components for large multi-cell stacks

» Ultra-thin down to 0.25 mm at custom porosity

BENEFITS

» High strength for high di erential pressure applications

» Ductile and machinable to allow for custom features

» Maintains porosity under very high compressive loads

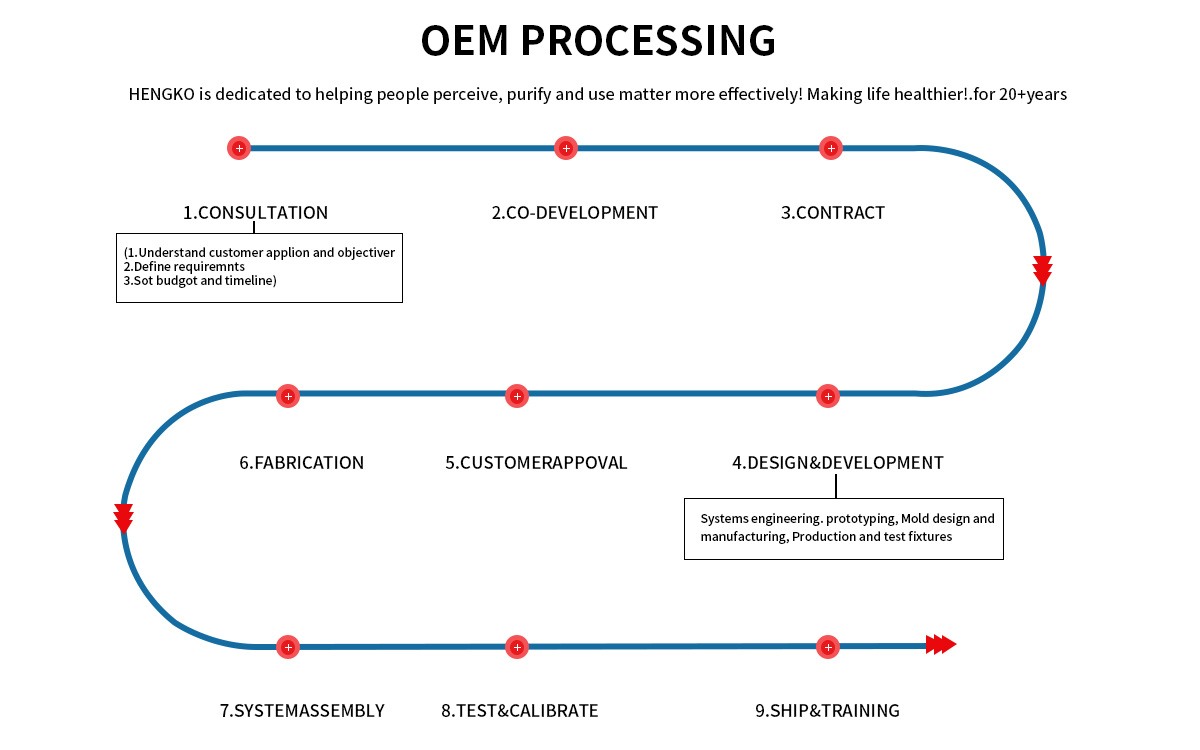

CUSTOMIZATION

We customize products around the following specipecations to meet the exacting demands on your application.

» Alloy

» Micron pore size

» Operating temperature

» Dimensions and tolerances

» Hardware and fittings

Corrosion resistant microns 316L stainless steel porous sintered filter sheet/plate for chemical industry, pharmaceutical industry

ENGAGE WITH US

When it comes to custom designs, our expertise is unmatched. With nearly 20+ years of experience in porous metal, let us design a component that is optimal and manufacturable. For a quote, email us at la@hengko.com or call 0755-88823250 and ask for one of our gas diffusion layer specialists.

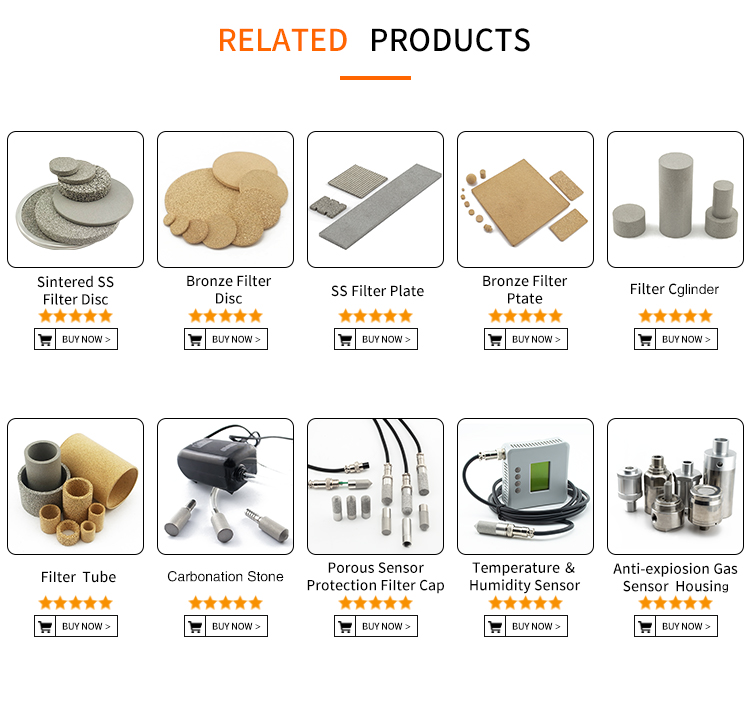

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!

Can't find a product that meets your needs? Contact our sales staff for OEM/ODM customization services!