-

SFB02 2 microns sintered stainless steel micro porous air diffusers spargers used in me...

Product Name Specification SFB02 D1/2''*H1-7/8'' 2um with 1/4'' Barb HENGKO carbonation stone is made of the food grad...

View Detail -

Nitrogenous wine Tool Diffusion Professional Effective Aeration Stone Beer Brewage 316L...

Product Name Specification SFB01 D1/2''*H1-7/8'' 0.5um with 1/4'' Barb SFB02 D1/2''*H1-7/8'' 2um with 1/4'' Barb SFB03 D1/2''*H1-7/8'' 0.5um...

View Detail -

Sintered stainless steel 316L micro air sparger and brewing carbonation ozone bubble st...

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through t...

View Detail -

Sintered stainless steel 316L aeration carbonation stone air stone ozone air sparger 0....

HENGKO carbonation stone is made of the food grade best stainless steel material 316L, healthier, practical, durable, high temperature resistant, and anti-co...

View Detail -

Stainless steel 316L SFC04 home brew 1.5″ Tri Clamp fitting 2 micron diffusion stone ai...

HENGKO sintered spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe ...

View Detail -

big batches hydrogen permeation micro bubble ozone sparger diffuser for diy home brewin...

1. Better Than Shaking a Keg! 2. Are you tired of carbonating your beer the unpredictable way? You crank up the PSI in the keg, shake, and wait with ...

View Detail -

Porous metal process filters, micro spargers for hydrogenated oil manufacturing

Product Description Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bub...

View Detail -

Sintered Medical Fine Diffuser Stone for Ozone Generator

HENGKO stainless steel ozone diffuser made of 316L stainless steel material has the advantage of durable, high temperature resistance, anti-pressure, and uni...

View Detail

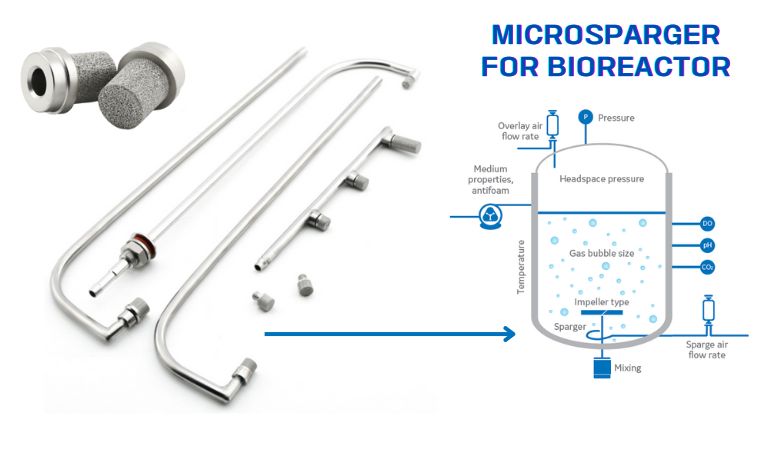

Main Features of Micro Sparger and Microsparger

The main features of micro spargers and microspargers are:

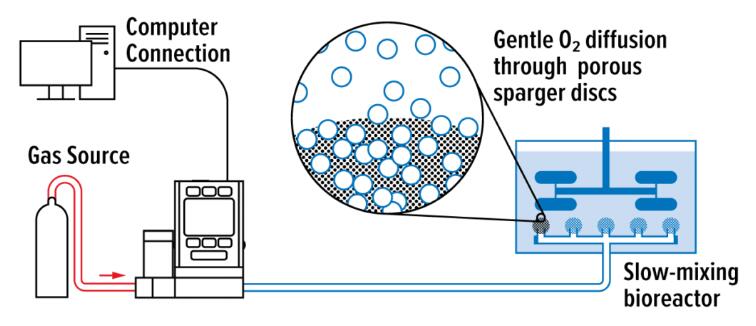

1. Smaller bubble size: Micro spargers and microspargers produce smaller bubbles than other types of spargers. This is important for a number of reasons. Smaller bubbles have a larger surface area, which means that they can dissolve more oxygen into the liquid. Smaller bubbles also create less shear stress on the cells, which can damage them.

2. More efficient oxygenation: Micro spargers and microspargers are more efficient at oxygenating the liquid than other types of spargers. This is because the smaller bubbles have a larger surface area, which allows them to dissolve more oxygen into the liquid.

3. Less likely to cause shear stress: Micro spargers and microspargers are less likely to cause shear stress on the cells than other types of spargers. This is because the smaller bubbles create less turbulence in the liquid.

4. More versatile: Micro spargers and microspargers can be used in a variety of applications. They are not limited to bioreactors, and can be used in other applications where it is important to have small, efficient bubbles.

Micro spargers and microspargers are a good choice for a number of applications, including:

* Bioreactors

* Fermenters

* Water treatment plants

* Wastewater treatment plants

* Chemical processing plants

* Food processing plants

* Pharmaceutical manufacturing

If you are looking for a sparger that is efficient at oxygenating the liquid, produces small bubbles,

and is less likely to cause shear stress on the cells, then a micro sparger or microsparger is a good option.

Contact HENGKO for Know More Details of Micro Sparger and Microsparger Today.

Maybe you can check our video to know more clear for the Microsparger for bioreactor.

if you also have project about bioreactor need some special Micro Sparger and Microsparger, then welcome to

contact us to know more detail for the products. You can send inquiry as follow form, also welcome to send email

to ka@heng.com to get best solution.

Types of Micro Sparger

Micro spargers are devices that are used to introduce gas into a liquid. They are commonly

used in bioreactors, where they are used to aerate the culture medium. Micro spargers are

made of a porous material, such as sintered stainless steel or ceramic, that has small holes

that allow the gas to flow through. The small pore size of the micro sparger creates fine bubbles,

which increase the surface area of the gas in contact with the liquid, and improve the

efficiency of gas transfer.

There are two main types of micro spargers:

* Sintered microspargers are made of a porous material,

such as sintered stainless steel, that has small holes that

allow the gas to flow through.

* Ceramic microspargers are made of a ceramic material, such as alumina or zirconia,

that has small holes that allow the gas to flow through.

Sintered microspargers are more common than ceramic microspargers because they are more

durable and less likely to clog. Ceramic microspargers are sometimes used in applications where

a high level of purity is required, such as in the pharmaceutical industry.

Micro spargers are available in a variety of sizes and shapes to meet the specific needs of the

application. They can be made with a single hole or with multiple holes. The size of the holes

determines the size of the bubbles that are created. Smaller holes create smaller bubbles,

which are more efficient at transferring gas.

| Type | Description | Advantages | Applications |

|---|---|---|---|

| Sintered | Made of sintered stainless steel with small holes | More durable, less likely to clog | Bioreactors, wastewater treatment, chemical production |

| Ceramic | Made of ceramic material with small holes | High level of purity | Pharmaceutical industry |

Micro spargers are an essential part of many bioreactors. They are used to aerate the culture medium,

which is necessary for the growth of many types of cells. Micro spargers are also used in other applications,

such as in the treatment of wastewater and in the production of chemicals.

Here are some of the benefits of using micro spargers:

* Increased gas transfer efficiency

* Improved mixing

* Reduced shear stress on cells

* Smaller bubbles for better gas-liquid contact

* Durable and long-lasting

If you are looking for a reliable and efficient way to introduce gas into a liquid, then a

micro sparger is a good option. Micro spargers are available in a variety of sizes and

shapes to meet the specific needs of your application.

Main Application of Sintered Micro Sparger and Microsparger

here are some main applications of micro spargers and microspargers:

1. Bioreactors:

Micro spargers are used in bioreactors to oxygenate the culture medium. This is important for the growth of cells and the production of proteins and other biomolecules.

2. Fermenters:

Microspargers are used in fermenters to oxygenate the medium and to control the temperature. This is important for the growth of yeast and bacteria, which are used to produce beer, wine, and other fermented beverages.

3. Water treatment plants:

Micro spargers are used in water treatment plants to aerate the water and to remove contaminants. This is important for providing clean and safe drinking water.

4. Wastewater treatment plants:

Micro spargers are used in wastewater treatment plants to aerate the wastewater and to remove contaminants. This is important for preventing the spread of disease and for protecting the environment.

5. Chemical processing plants:

Microspargers are used in chemical processing plants to mix and aerate the chemicals. This is important for the production of a variety of products, including plastics, fertilizers, and pharmaceuticals.

6. Food processing plants:

Micro spargers are used in food processing plants to mix and aerate the food. This is important for the production of a variety of products, including bread, yogurt, and ice cream.

7. Pharmaceutical manufacturing:

Microsparger are used in pharmaceutical manufacturing to mix and aerate the media. This is important for the production of a variety of drugs, including antibiotics, vaccines, and hormones.

Sintered Micro spargers and Microsparger are a versatile and effective way to oxygenate liquids and to mix and aerate solids.

They are used in a wide variety of industries, including the pharmaceutical, food, and chemical industries.

FAQ for the Micro Sparger and Microsparger for Bioreactor

1. What is a Sparger in Bioreactor?

Generally, a Bioreactor is a System that uses enzymes or biological functions of organisms(such as microorganisms) to carry out biochemical reactions in vitro.

During this process, HENGKO's micro sparger offers sufficient air or pure oxygen for the reaction.

2. What are Two Types of Bioreactor?

There are many different types of bioreactors, but two of the most common are stirred-tank bioreactors and airlift bioreactors.

1. Stirred-tank bioreactors are the most common type of bioreactor. They are cylindrical vessels that contain a stirrer that helps to mix the culture medium and oxygenate the cells. Stirred-tank bioreactors can be used to grow a variety of cells, including bacteria, yeast, and mammalian cells. They are also used to produce a variety of products, including antibiotics, enzymes, and vaccines.

2. Airlift bioreactors are a type of bioreactor that uses air to circulate the culture medium and oxygenate the cells. Airlift bioreactors are less expensive to operate than stirred-tank bioreactors, and they can be used to grow cells in larger volumes. Airlift bioreactors are often used to produce products that are sensitive to shear stress, such as monoclonal antibodies.

Here is a table that summarizes the key differences between stirred-tank bioreactors and airlift bioreactors:

| Feature | Stirred-tank bioreactor | Airlift bioreactor |

|---|---|---|

| Shape | Cylindrical | Conical or spherical |

| Mixing | Stirrer | Air |

| Oxygenation | Mechanical | Diffusion |

| Cost | More expensive | Less expensive |

| Volume | Smaller | Larger |

| Applications | Wide range of applications | Sensitive products |

In addition to stirred-tank bioreactors and airlift bioreactors, there are many other types of bioreactors.

Some of the other types of bioreactors include:

- Bubble column bioreactors

- Fluidized bed bioreactors

- Packed bed bioreactors

- Photo bioreactors

The type of bioreactor that is best for a particular application will depend on a number of factors,

including the type of cells that are being grown, the product that is being produced, and the desired scale of production.

3. Which Bioreactor is Used in Pharmaceutical Industry ?

Both stirred-tank bioreactors and airlift bioreactors can used in the pharmaceutical industry. The type of bioreactor that is used will depend on the specific application.

For example, stirred-tank bioreactors are often used to produce antibiotics, while airlift bioreactors are often used to produce monoclonal antibodies.

Here are some of the most common bioreactors used in the pharmaceutical industry:

1. Stirred-tank bioreactors: These are the most common type of bioreactor used in the pharmaceutical industry. They are cylindrical vessels that contain a stirrer that helps to mix the culture medium and oxygenate the cells. Stirred-tank bioreactors can be used to grow a variety of cells, including bacteria, yeast, and mammalian cells. They are also used to produce a variety of products, including antibiotics, enzymes, and vaccines.

2. Airlift bioreactors: These are a type of bioreactor that uses air to circulate the culture medium and oxygenate the cells. Airlift bioreactors are less expensive to operate than stirred-tank bioreactors, and they can be used to grow cells in larger volumes. Airlift bioreactors are often used to produce products that are sensitive to shear stress, such as monoclonal antibodies.

3. Bubble column bioreactors: These bioreactors consist of a vertical column of liquid with a sparger at the bottom that introduces gas into the liquid. The bubbles of gas rise through the liquid, mixing it and providing oxygen to the cells. Bubble column bioreactors are often used to grow cells in large volumes.

4. Fluidized bed bioreactors: These bioreactors consist of a bed of solid particles that is fluidized by a stream of liquid. The cells are grown on the surface of the particles, and the liquid provides oxygen and nutrients to the cells. Fluidized bed bioreactors are often used to grow cells in large volumes.

5. Packed bed bioreactors: These bioreactors consist of a column of packed particles that is filled with cells. The liquid flows through the column, providing oxygen and nutrients to the cells. Packed bed bioreactors are often used to grow cells in small volumes.

6. Photo bioreactors: These bioreactors use light to provide energy for the growth of cells. Photo bioreactors are often used to grow photosynthetic cells, such as algae and bacteria.

The type of bioreactor that is best for a particular application will depend on a number of factors, including the type of cells that are being grown, the product that is being produced, and the desired scale of production.

4. What are the parts of a bioreactor?

Normally, This bioreactor consists of different types of parts such as “an agitator system,”

“A foam control system,” “A Baffles system,” “A PH & temperature control system,”

“A Farmentar vessel,” “Aeration system” and “An Impeller system.” Each of these

parts has its necessary usage to perform this bioreactor.

6. Microsparger vs Ring Sparger

microspargers and ring spargers are two types of spargers that are used in bioreactors to introduce gas into the liquid. Actually Now Almost to Use Sintered microspargers are made of a porous material, such as sintered stainless steel, that has small holes that allow the gas to flow through. Ring spargers are made of a solid material, such as stainless steel, that has a ring shape with a number of holes in it.

1. Sintered microspargers have a number of advantages over ring spargers. They are more efficient at oxygenating the liquid, they produce smaller bubbles, and they are less likely to cause shear stress on the cells. However, sintered microspargers are more expensive than ring spargers.

2. Ring spargers are less efficient at oxygenating the liquid than sintered microspargers, they produce larger bubbles, and they are more likely to cause shear stress on the cells. However, ring spargers are less expensive than sintered microspargers.

The type of sparger that is best for a particular application will depend on a number of factors, including the type of cells that are being grown, the product that is being produced, and the desired scale of production.

Here is a table that summarizes the key differences between sintered microspargers and ring spargers:

| Feature | Sintered microsparger | Ring sparger |

|---|---|---|

| Efficiency | More efficient | Less efficient |

| Bubble size | Smaller bubbles | Larger bubbles |

| Shear stress | Less likely to cause shear stress | More likely to cause shear stress |

| Cost | More expensive | Less expensive |

Here are some additional considerations when choosing a sparger:

1. Type of cells: Some cells are more sensitive to shear stress than others. If you are growing cells that are sensitive to shear stress, you will need to choose a sparger that is less likely to cause shear stress.

2. Product: Some products are more sensitive to oxygen than others. If you are producing a product that is sensitive to oxygen, you will need to choose a sparger that is more efficient at oxygenating the liquid.

3. Scale of production: If you are producing a product on a large scale, you will need to choose a sparger that can handle the large volume of liquid.

Ultimately, the best way to choose a sparger is to consult with a bioreactor expert. They can help you to choose the sparger that is best for your specific application.