1/2″ VCR Gasket Stainless Steel Porous Filter for Semiconductor Industry Ultra-High Purity VCR Fitting

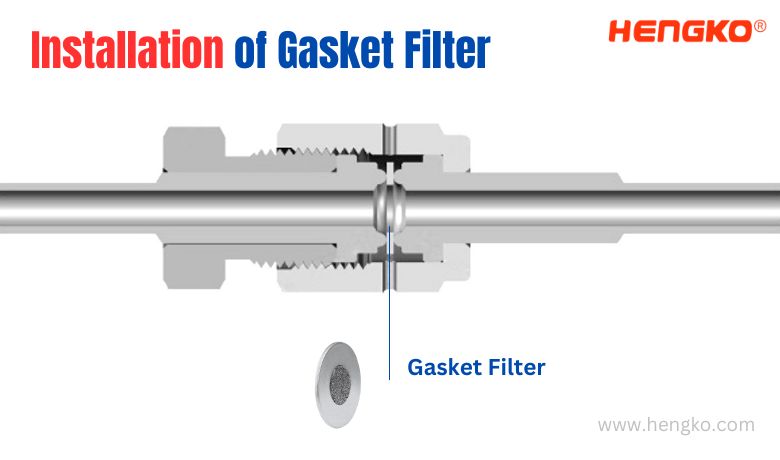

What Is a VCR Gasket Filter?

A VCR Gasket Filter is a high-purity sealing gasket integrated with a sintered stainless-steel micro-porous filter,

designed to remove particles from ultra-high purity (UHP) gases while maintaining the metal-to-metal seal of VCR fittings.

Unlike standard VCR gaskets that only provide sealing, a VCR filter gasket adds an internal filtration layer—capturing particles

at 0.2–10 μm before they enter mass flow controllers, analyzers, gas cabinets, and semiconductor process lines.

This makes it essential in:

*Semiconductor fabrication

*Specialty gas distribution

*Research-grade gas systems

*High-purity analytical instruments

Compatible with Swagelok VCR fittings, these filter gaskets provide particle control without

altering existing system interfaces.

![]()

Porous Metal Gasket Filter for Semiconductor Applications

A Reliable Solution for Protecting Precision Gas Systems:

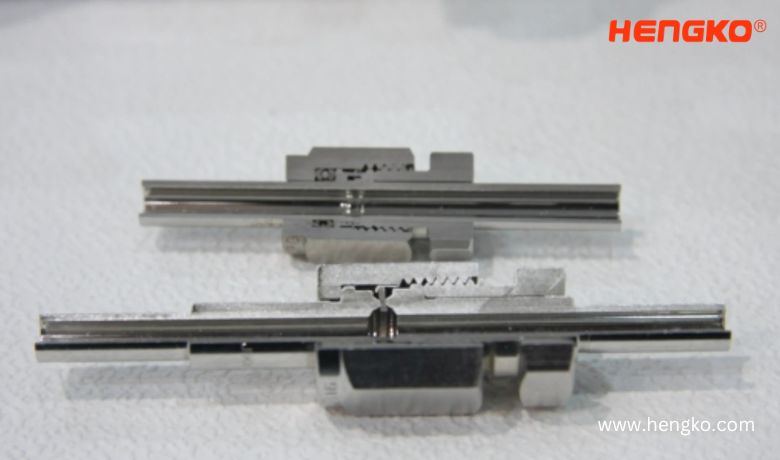

1.) Designed specifically for semiconductor gas distribution systems, this all-metal filter offers seamless compatibility

with 1/4", 3/8", and 1/2" VCR standard gasket interfaces.

2.) The gasket-style design ensures easy installation, making it an essential protective barrier for

MFC (Mass Flow Controller) modules, precision valves, and pressure regulators.

3.) Capable of withstanding temperatures up to 400°C, the Porous Metal Gasket Filter effectively blocks particle intrusion,

safeguarding sensitive gas components.

4.) By preventing contamination-related leaks, it extends equipment lifespan and reduces maintenance costs.

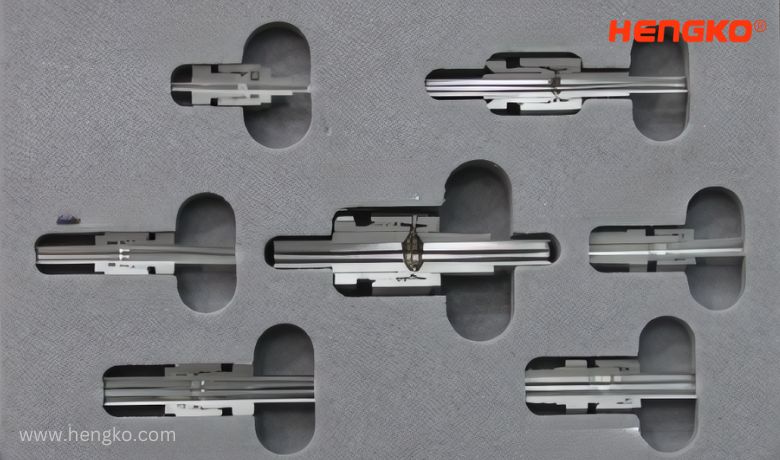

5.) Available in both low-pressure and high-pressure models, this filter can be retrofitted into existing piping systems,

providing a cost-effective solution for protecting precision equipment from contamination.

Specification

| Technical Parameter | Details |

|---|---|

| Filter Material | Sintered 316L stainless steel powder |

| Housing/Gasket Material | 316L stainless steel |

| Surface Finish (Exterior) | Ra ≤ 1.6μm |

| Surface Finish (Interior) | Polished + electropolished, Ra ≤ 0.2μm |

| Maximum Operating Temperature | 400°C |

| Particle Retention Efficiency | ≥99.9999999% (9 LRV) @ 100 slpm (based on MPPS, for all particles) |

| Particle Size Capture | ≥0.3μm |

| Compatible Sizes | 1/4’’, 3/8’’, and 1/2’’ VCR standard gasket interfaces |

| Application | Semiconductor gas distribution systems, MFC modules, precision valves, and pressure regulators |

| Available Models | Low-pressure and high-pressure versions |

Product Features

| Product Features | Details |

|---|---|

| Material | Entirely constructed from 316L stainless steel |

| Installation | Can be used as a surface-sealing filter, eliminating the need for additional work such as cutting or welding pipes for installation |

| Durability | Resistant to high temperature, high pressure, and corrosion |

Low Pressure Series

Suitable for low-pressure system pipelines

*Maximum operating pressure 0.98Mpa

*Flow range: 0~100slpm

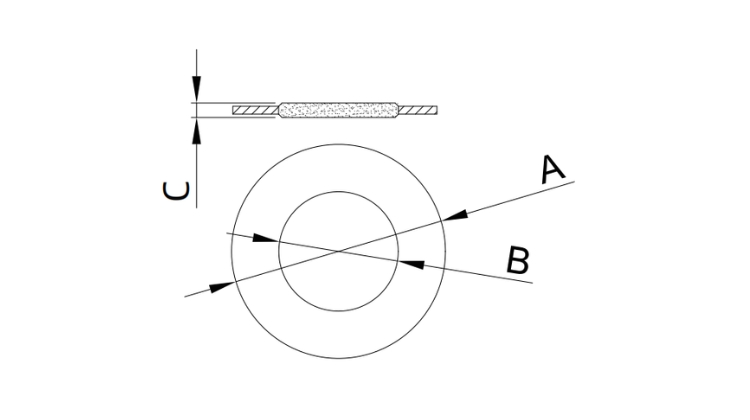

| Product Model | Filter Accuracy | Gasket Size | A | B | C |

| Z01B-00690 | 0.3 µm | 1/4" VCR | Φ11.90 mm | Φ5.50 mm | 0.70 mm |

| Z01B-00640 | 1/2" VCR | Φ19.80 mm | Φ11.20 mm | 0.70 mm | |

| Z01B-00691 | 3/4" VCR | Φ28.00 mm | Φ16.80 mm | 0.70 mm | |

| Z01B-00693 | 1.0 µm | 1/4" VCR | Φ11.90 mm | Φ5.50 mm | 0.70 mm |

| Z01B-00694 | 1.0 µm | 1/2" VCR | Φ19.80 mm | Φ11.20 mm | 0.70 mm |

| Z01B-00692 | 1.0 µm | 3/4" VCR | Φ28.00 mm | Φ16.80 mm | 0.70 mm |

| Z01B-00725 | 5 µm | 1/4" VCR | Φ11.90 mm | Φ5.70 mm | 0.70 mm |

| Z01B-00726 | 10 µm | 1/4" VCR | Φ11.90 mm | Φ5.70 mm | 0.70 mm |

Filtration accuracy (0.01–60 µm) and dimensions are customizable!

Application

Applications of Porous Stainless Steel VCR Gasket Filter

1.Semiconductor Manufacturing:

*Used in gas distribution systems to filter particles and protect sensitive components such as mass flow controllers (MFCs), valves, and regulators.

*Ensures a clean gas supply in processes like chemical vapor deposition (CVD) and etching, preventing particle contamination that can lead to product defects.

*ALD, CVD, PVD

*Etch / Lithography gas lines

*UHP gas cabinets

*Gas purification skids

2.Pharmaceutical and Biotech Industries:

*Ideal for use in high-purity gas delivery systems for critical processes such as gas sterilization or gas mixing in drug manufacturing.

*Ensures the integrity of the gas used in production by filtering out contaminants that could affect the product quality.

3.Aerospace and High-Tech Manufacturing:

*Applied in precision gas flow control systems used for the manufacture of advanced materials, coatings, and components in aerospace.

*Withstands extreme temperatures and pressures, providing long-lasting particle filtration in demanding environments.

4.Chemical Processing:

*Effective in gas supply lines in chemical plants where high temperatures, pressures, and corrosive environments are present.

*Prevents particulate contamination that could disrupt chemical reactions or lead to equipment failure.

*Gas chromatographs

*Mass spectrometers

*Environmental analyzers

5.Laboratory and Research Facilities:

*Used in high-precision gas delivery systems for scientific instruments such as gas chromatographs, mass spectrometers, or other sensitive analytical devices.

*Protects delicate instruments from particulate contamination, improving accuracy and longevity.

6.High-Purity Gas Distribution:

*Essential for systems requiring ultra-clean gas, such as those used in electronics manufacturing, where contaminants can disrupt the manufacturing process.

*The 316L stainless steel construction ensures durability and chemical resistance, making it suitable for harsh operating environments.

7.Cryogenic Gas Systems:

*Suitable for cryogenic gas delivery systems where it is crucial to filter out particles that could affect the performance of cryogenic processes in industries like medical gas supply or liquefied gas handling.

8.Oil and Gas Industry:

*Used in gas filtration systems in refineries or petrochemical plants, ensuring that contaminants are removed from gas streams, protecting equipment from fouling or wear.

Key Benefits for Applications:

*High-temperature and high-pressure resistance allows the filter to function reliably in extreme conditions.

*Corrosion resistance of 316L stainless steel ensures long service life, even in chemically aggressive environments.

*Convenient installation without the need for additional cutting or welding makes it easy to retrofit into existing systems.

Why Use a VCR Gasket Filter?

● Dual Function: Seal + Filtration

One component provides gas-tight sealing and precise particle filtration.

● Protect Critical UHP Components

Removes particulates that damage:

*Mass Flow Controllers (MFC)

*Pressure regulators

*Gas analyzers

*UHP delivery lines

● Maintain Ultra-High Purity Standards

Filters maintain:

*≤ 1 ppb contamination levels

*ISO / SEMI purity specifications

● No Modification Required

Fits directly between standard male and female VCR faces—no system redesign needed.

● Stainless Steel Sintered Structure

Maintains:

*High temperature resistance

*Mechanical strength

*Corrosion resistance

*Consistent micron rating under pressure

Comparison: Standard VCR Gasket vs VCR Filter Gasket

| Feature | Standard VCR Gasket | VCR Filter Gasket |

|---|---|---|

| Seal | ✔ | ✔ |

| Particle Filtration | ✘ | ✔ 0.2–10 μm |

| Protects MFC | ✘ | ✔ |

| Prevents contamination | ✘ | ✔ |

| Typical Applications | Basic sealing | UHP systems / Semiconductor |

| Price | Low | Slightly higher |

| Value | Basic | High (reduces downtime & contamination) |

Filter gasket = Reduced equipment wear + Increased purity + Lower maintenance cost

Custom Manufacturing & OEM Options (HENGKO Advantage)

We customize:

*Micron rating (0.1–30 μm)

*Outer / inner diameter

*Thickness and porosity

*Material options (316L / Nickel Alloy / Hastelloy)

*Filtration distribution curves

*Flow rate optimization

OEM / ODM services include:

*Private label branding

*Custom packaging

*Engineering design for gas system integrators

We support long-term supply for semiconductor equipment manufacturers and global UHP gas distributors.

Ready to optimize your gas distribution system with a high-performance Porous Stainless Steel VCR Gasket Filter?

Contact HENGKO today to discuss your specific requirements.

Our expert team is here to provide customized OEM solutions tailored to your industry needs.

Reach out via email at ka@hengko.com to get started on designing the perfect VCR gasket filter for your applications!

Send your message to us:

*High Purity Gas Filter Assembly

*Sintered Metal Sparger

*Metal Porous Material Technology