-

Compressed air stainless steel wire mesh filter cartridge for sterile process air and g...

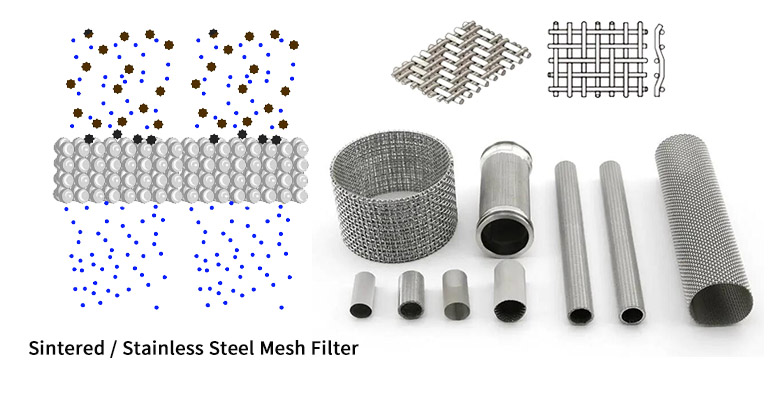

Sintering is a process that entails the application of heat and pressure to bond the contact points of all wires together to form a securely fused wire mesh ...

View Detail -

Sintered stainless steel wire mesh filter tube (filter cylinder) used in petroleum, che...

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration coolin...

View Detail -

1.0-100um sintered porous metal stainless steel cartridge filter mesh perform in liquid...

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration coolin...

View Detail -

30 40 90 Microns Sintered SUS 304 SS 316L stainless steel composite media filters for c...

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particles, transpiration coolin...

View Detail -

Sintered Filter Cartridges for Medical Filtration Applications -HENGKO

HENGKO has developed an all-metal sterilizing grade membrane for medical filtration applications. This material is ideally suited for applications in medical...

View Detail

Main Feature of Stainless Steel Mesh Filters :

1. the Vast array of filtration scores to avoid any size of particles

2. Wire mesh can be custom fabricated to any shape or application by stamped or cut

3. Easy to Clean and backwash

4 Conveniently workable, Special styles for flexibility in industrial fields

5. Improved mechanical strength with excellent resilience Suitable under thermal and

also extremely corrosive problem

6. Mesh can be marked or reduced to the size

7. Wire mesh can be rolled, welded, sintered, and soldered

8. Easy to clean and backwash

4 - Function of Stainless Steel Mesh Filters

1. To clear away undesirable fragments as well as impurities from various fluids

2. To finish the filtration procedure efficiently

3. To change traditional filter mesh under harsh environment

4. Prevent damage to equipment

Application of Stainless Steel Mesh Filter :

Stainless steel mesh filters are highly versatile filtration solutions suitable for a wide range of applications. Their corrosion-resistant construction and customizable mesh patterns enable precise filtration of particles, contaminants, and debris.

Filtration of Liquids

Stainless steel mesh filters are ideal for filtering liquids such as:

- Beverages - Prevent sediment and ensure clarity in bottled beverages, fruit juices, and bottled water. • Process liquids - Filter impurities from chemicals, pharmaceuticals, food products, and wastewater. • Pool water - Remove debris, leaves, and other contaminants to keep pool water clean and circulating properly.

Separation of Solids

Stainless steel mesh filters are also effective at separating solids such as: • Food particles - Filter out shells, pits, stems, and other food particles during processing and preparation. • Recyclables - Separate paper, plastics, metals, and glass during recycling sorting operations. • Aggregates - Classify sand, gravel, crushed stone, and other aggregates by size for construction and industrial applications.

Customizable Solutions

Stainless steel mesh filters can be customized in terms of mesh type (woven vs. expanded), mesh count (threads per inch), and filter area to suit a wide range of filtration needs. Larger filter areas and lower mesh counts result in coarser filtration while higher mesh counts and smaller filter areas provide finer filtration.

With excellent corrosion resistance, durability, and customizable filtration, stainless steel mesh filters represent a highly versatile and professional solution for applications where precise and reliable filtration is required.

-

Aerospace

-

Chemical industry and oil/gas industries

-

Edible oil Industry

-

Metals and mining industry

-

Solvents, Paints

-

Pharmaceutical industry

-

Water and Waste Management

-

High viscosity liquids

-

sea-water desalination

-

Food and Beverage

-

Filtration, Sifting, Sizing

-

Vents

-

Baskets

-

Strainers

-

Faucet Screens

-

Insect Screens

-

Decorative wire mesh grilles

-

Guards

-

Decorative/craft applications

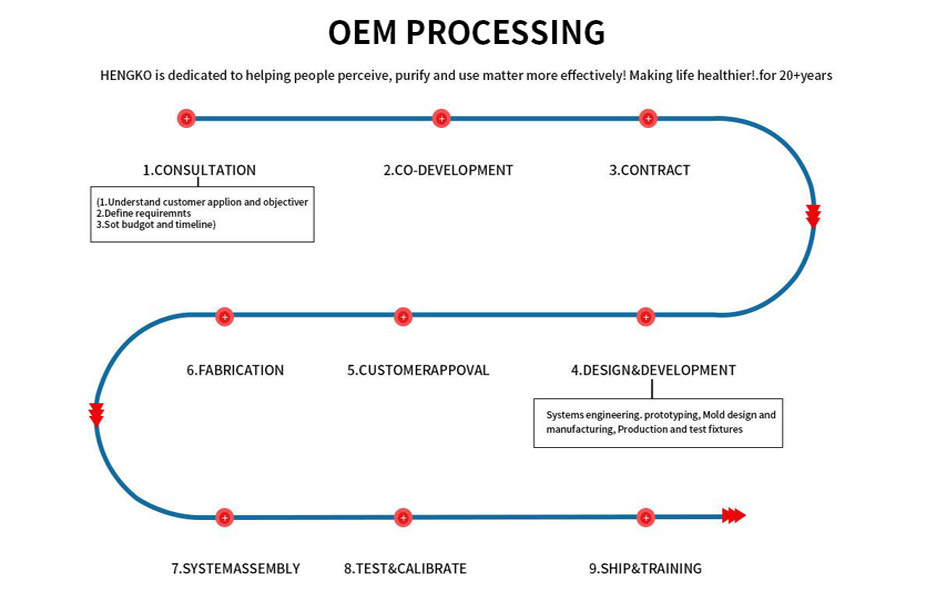

How to Customize Sintered Stainless Steel Mesh Filter

if you have Special Requirements for Sintered Stainless Steel Filter for your projects and can not find the same or

similar Filter products, Welcome to contact HENGKO to work together to find the best solution, and here is the

process of O.E.M Sintered Stainless Steel Mesh Filter,

HENGKO is a professional manufacturer of sintered stainless steel mesh filters. We can provide customized sintered

stainless steel mesh filters according to your special requirements if the standard products cannot meet your needs.

The process of O.E.M sintered stainless steel mesh filter includes:

1.Technical consultation:

Our engineers will consult with you on the specific requirements of your projects to determine the appropriate material,

mesh size, thickness, etc. of the sintered stainless steel mesh filter.

2.Sample making:

We will make samples based on the consultation results and send them to you for testing and verification.

Once the samples meet your requirements, we will start mass production of the sintered stainless steel mesh filters.

4.Inspection:

All products will go through strict inspections to ensure they meet the standards before delivery.

5.Packaging and shipment:

The inspected products will be packaged and shipped to you via the shipping method you specified.

We have advanced equipment and professional technicians to produce high-quality sintered stainless steel mesh filters.

We also have a strict quality management system to ensure stable and reliable product quality. If you have any other needs,

please contact us at any time. We are committed to providing you with the best solutions and services.

OEM Order Process List

1. Consultation and Contact HENGKO At First

2. Co-Development

3. Make a Contract

4. Design & Development

5. Customer Approval

6. Fabrication /Mass Production

7. System assembly

8. Test & Calibrate

9. Shipping & Installation

What HENGKO Can Supply For Stainless Steel Mesh Filter

HENGKO Support Various Applications on your Different requirements for Sintered Stainless Steel Mesh Filter

with customize and innovative designs as clients requirements Our Stainless Mesh Filter have a long-standing

history of being commonly used in superior industrial filtration, dampening, sparger, sensor protection, pressure

regulation and many more applications.

✔ Sintered Mesh Filter Industry Top Manufacturer of Over 20-years

✔ Unique Designs as Different size, Melt, Layers and Shapes

✔ Top Quality CE Standard to manufacturing, Stable shape, Meticulous Work

✔ Fast Solution for after-sale service

✔ Many Experience in Various filters Applications in Chemical, Food, and Beverage Industries etc

In the past 20-years, HENGKO work for many famous university all over the world, especial the lab of university,

Physics and Chemistry Laboratory, R&D laboratories of various chemical, petroleum, and food products, R&D and

production departments of production enterprises, we got many projects experience in the stainless steel mesh filter,

sintered mesh filter, so we can fast supply you perfect solution for your devices and project.

FAQ for Stainless Steel Mesh Filter

1. Can you make 5 micron stainless steel mesh filter ?

Yes, we can OEM any size and any thickness 5 micron stainless steel mesh filter,

or 5 Micron 3 Layer Sintered Stainless Mesh, 5 Micron 5 Layer Sintered Stainless Mesh

Also, we can custom any pore size, like 0.2 - 200 micron Stainless Steel Mesh Filter for

your projects.

2. What Does the Stainless Steel Mesh Do?

Stainless steel mesh is a metal screen made using stainless steel wire or other alloys. It is

commonly used in various applications, including filtration, sieving, straining, and screening.

The mesh is typically used in industries such as food processing, pharmaceuticals, chemical

processing, mining, and consumer products. Because stainless steel is resistant to corrosion

and has a high strength-to-weight ratio, it is an ideal material for use in the mesh. The mesh

can be made in various sizes and shapes, depending on the specific application it is intended for.

3. Why is Mesh Wire So Important?

Wire mesh is important in many industries and applications because of its versatility, strength,

and durability. It is used in many applications, including filtration, sieving, straining, and screening,

and is commonly used in food processing, pharmaceuticals, chemical processing, and mining.

Mesh wire is also used in consumer products, such as screens for doors and windows.

4. How Does Wire Mesh Work?

Wire mesh is a grid or screen made up of interconnected wire strands. It is used in various

applications, including filtration, sieving, straining, and screening. For mesh, a material sample

is placed on top of the mesh, and the mesh is shaken or vibrated. The material will pass through

the openings in the mesh, but any particles or objects that are too large to pass through the

mesh will be retained on top of the mesh. It allows the material to be separated into different

size ranges or components.

5. Are Metal Mesh Filters Good?

Metal mesh filters are a type of filter that uses a mesh made of metal wire or other alloys to

remove particles or other materials from a fluid or gas. They are commonly used in various

industries, including food processing, pharmaceuticals, chemical processing, and mining,

as well as in consumer products. Metal mesh filters are generally considered effective and

reliable for many filtration applications. They are durable, have a high strength-to-weight ratio,

and resist corrosion, making them well-suited for use in a wide range of environments.

In addition, metal mesh filters can be easily cleaned and reused, which makes them

cost-effective and environmentally friendly.

6. Is Stainless Steel Mesh Food Safe?

Stainless steel mesh special 316L stainless steel mesh filter is generally considered

safe for food processing and handling. Stainless steel is a non-toxic and non-leaching

material, which means it does not release any substances into food that could harm

human health. In addition, stainless steel is corrosion-resistant and easy to clean,

making it an ideal material for food processing and handling applications.

How do you clean a stainless steel mesh filter?

There are several methods for cleaning the stainless steel mesh filter, depending on the

specific type of filter and the amount of cleaning needed. Here are some general steps

that you can follow in cleaning a stainless steel mesh filter:

1. Rinse the filter with water to remove any loose debris or particles.

2. If the filter is not too dirty, you can use a soft-bristled brush or a soft cloth to gently scrub

away any remaining dirt or grime.

3. If the filter is very dirty, you can soak it in warm water and mild detergent for a few minutes

to loosen any stubborn dirt or grime.

4. Rinse the filter thoroughly with water to remove any soap or cleaning solution.

5. Dry the filter completely before using it again.

It is important to avoid using abrasive cleaners or brushes, as these can damage the

mesh and reduce its effectiveness. Drying the filter before using it again is also important,

as moisture can cause the mesh to rust or corrode.

6. What are the benefits of stainless steel mesh filters?

Stainless steel mesh filters offer several key benefits over other filter materials. They are extremely durable and long-lasting, able to withstand high pressures and temperatures without damage. They are also corrosion-resistant, chemically inert, and non-reactive so they can be used with a wide range of fluids. Stainless steel mesh filters are also very fine, able to filter even small particles and microorganisms.

7. What micron ratings are available?

Stainless steel mesh filters are available in a range of micron ratings, from 0.5 microns up to 100 microns. The micron rating refers to the size of particles that will pass through the filter. Finer micron ratings like 0.5-5 microns are good for filtering particles and microorganisms, while larger micron ratings of 20-100 microns are better for filtering larger debris and sediment.

8. How are stainless steel mesh filters used?

Stainless steel mesh filters have a wide range of applications and are used in many industries. Some common uses include: • Filtration of liquids and gases in chemical processing, pharmaceuticals, food and beverage, and biotechnology. • Sterilization of air, gases, and liquids by filtering out microorganisms. • Clarification of liquids by removing particles, sediments, and contaminants. • Pre-filtration for membrane filters to prevent clogging. • Separation of particles for sampling and analysis. • Filtration of abrasive liquids and slurries. • Filtration of corrosive liquids and gases. • Filtration of high-temperature liquids and gases.

9. What is stainless steel mesh filter?

Stainless steel mesh filters are precision-engineered filters made of corrosion-resistant stainless steel mesh. They are designed to filter particles, contaminants, and debris from liquids and gases while allowing the medium to pass through.

10.What are the benefits of stainless steel mesh filters?

Stainless steel mesh filters offer several key benefits over other filter materials. They are extremely durable and long-lasting, able to withstand high pressures and temperatures without damage. They are also corrosion-resistant, chemically inert, and non-reactive so they can be used with a wide range of fluids. Stainless steel mesh filters are also very fine, able to filter even small particles and microorganisms.

11.What micron ratings are available?

Stainless steel mesh filters are available in a range of micron ratings, from 0.5 microns up to 100 microns. The micron rating refers to the size of particles that will pass through the filter. Finer micron ratings like 0.5-5 microns are good for filtering particles and microorganisms, while larger micron ratings of 20-100 microns are better for filtering larger debris and sediment.

12.How are stainless steel mesh filters used?

Stainless steel mesh filters have a wide range of applications and are used in many industries. Some common uses include: • Filtration of liquids and gases in chemical processing, pharmaceuticals, food and beverage, and biotechnology. • Sterilization of air, gases, and liquids by filtering out microorganisms. • Clarification of liquids by removing particles, sediments, and contaminants. • Pre-filtration for membrane filters to prevent clogging. • Separation of particles for sampling and analysis. • Filtration of abrasive liquids and slurries. • Filtration of corrosive liquids and gases. • Filtration of high-temperature liquids and gases.

13.What are the advantages of stainless steel mesh filters?

Stainless steel mesh filters offer significant advantages over other materials. They are extremely durable and long-lasting, able to withstand high pressures, temperatures, and high flow rates without damage. They are also corrosion-resistant and chemically inert, suitable for use with a wide range of fluids including acids, bases, and solvents. Stainless steel mesh filters are very fine, capable of filtering even small particles, microorganisms, and contaminants. They can also be autoclaved for sterilization and reused.

14.What is stainless steel mesh filter?

Stainless steel mesh filters are precision-engineered filters made of corrosion-resistant stainless steel mesh. They are designed to filter particles, contaminants, and debris from liquids and gases while allowing the medium to pass through.

15.What are the benefits of stainless steel mesh filters?

Stainless steel mesh filters offer several key benefits over other filter materials. They are extremely durable and long-lasting, able to withstand high pressures and temperatures without damage. They are also corrosion-resistant, chemically inert, and non-reactive so they can be used with a wide range of fluids. Stainless steel mesh filters are also very fine, able to filter even small particles and microorganisms.

16.What micron ratings are available?

Stainless steel mesh filters are available in a range of micron ratings, from 0.5 microns up to 100 microns. The micron rating refers to the size of particles that will pass through the filter. Finer micron ratings like 0.5-5 microns are good for filtering particles and microorganisms, while larger micron ratings of 20-100 microns are better for filtering larger debris and sediment.

17.How are stainless steel mesh filters used?

Stainless steel mesh filters have a wide range of applications and are used in many industries. Some common uses include: • Filtration of liquids and gases in chemical processing, pharmaceuticals, food and beverage, and biotechnology. • Sterilization of air, gases, and liquids by filtering out microorganisms. • Clarification of liquids by removing particles, sediments, and contaminants. • Pre-filtration for membrane filters to prevent clogging. • Separation of particles for sampling and analysis. • Filtration of abrasive liquids and slurries. • Filtration of corrosive liquids and gases. • Filtration of high-temperature liquids and gases.

18. What are the advantages of stainless steel mesh filters?

Stainless steel mesh filters offer significant advantages over other materials. They are extremely durable and long-lasting, able to withstand high pressures, temperatures, and high flow rates without damage. They are also corrosion-resistant and chemically inert, suitable for use with a wide range of fluids including acids, bases, and solvents. Stainless steel mesh filters are very fine, capable of filtering even small particles, microorganisms, and contaminants. They can also be autoclaved for sterilization and reused.

19.What industries use stainless steel mesh filters?

Stainless steel mesh filters are used in many industries including:

• Chemical and pharmaceutical processing - For filtration and separation of chemicals, solvents, and pharmaceutical ingredients.

• Food and beverage - For clarification, sterilization, and filtration of liquids and gases.

• Biotechnology - For sterilization, clarification, and separation of biological samples and cultures.

• Microbiology - For sterilization and filtration of air, gases, and liquids used in microbiology experiments and research.

• Healthcare - For sterilization of medical gases, filtration of IV fluids, and clarification of laboratory samples.

• Semiconductor manufacturing - For filtration of corrosive chemicals and abrasive slurries used in chip fabrication.

• Nuclear industries - For filtration of radioactive fluids and high-temperature steam.

• Power generation - For filtration of hot gases, abrasive particles, and contaminants in fossil fuel power plants.

• Metalworking - For filtration of cutting fluids, coolants, and metal particles.

• Pulp and paper - For clarification and de-inking of pulp and filtration of process waters.

20. What types of stainless steel mesh filters are available?

The main types of stainless steel mesh filters include:

• Woven mesh filters - Made by electroforming stainless steel wire into mesh. Tight mesh for high filtration.

• Sintered mesh filters - Made by sintering powdered stainless steel into mesh. High porosity for low pressure drop.

• Perforated plate filters - Stainless steel plates with holes punched or laser cut in specific patterns.

• Bag filters - Stainless steel mesh bags or sleeves used as disposable or reusable filter media.

• Cylindrical filters - Stainless steel mesh wrapped around the outside of a support tube or cage.

• Panel filters - Stainless steel mesh sheets with a frame to form flat panel filters.

• Bag-in/bag-out filters - Disposable stainless steel mesh bag filters that can be removed and replaced while the filter housing remains in line.

Still Have Questions and Like to Know More Details For the Sintered Stainless Steel Mesh Filter, Please feel Free To

Contact Us Now. Also You Can Send Us Email Directly As Follow : ka@hengko.com

We Will Send Back With 24-Hours, Thanks for Your Patient !