-

Stainless Steel Sintered Porous Metal Turbine Filters for Air Inlet Filtration ( Used i...

Filtration (add porous metal filter) is critical for turbine engines. If sub-micron particles, liquids, and dissolved contaminants like air and water-borne s...

View Detail -

Pharmacy Stainless Steel Sintered Porous Metal Filter Ø12×20 mm

Sintered filter is widely used in industry. Customize different sintered metal structure products to suit your use environment! Features: Material: SS...

View Detail -

Sintered Porous Metal Filter Cylindrical Element for Full-Cale Process Filters

The HENGKO porous metal filter can separate solids from liquids and gases in a wide variety of applications. Uses include process filtration, sampling filter...

View Detail -

47mm Porous Disc Filter 316L SS Sintered Metal Filter for Laboratory Bench Scale Testing

HENGKO’s bench-top filter (47mm disc test filter), our 47mm disc filter, is a simple, inexpensive way to effect liquid-solid and gas-solid separations with e...

View Detail -

HENGKO Customized 316L Powder Sintered Porous Metal Stainless Steel Filter With Externa...

Products Description The stainless steel muffler is a muffler made of all stainless steel or with a stainless steel tube or outer shell. HENGKO stainless s...

View Detail -

HENGKO 316L sintered stainless steel filter porous metal filter element

Products Description HENGKO produces porous metal filter elements in a variety of materials, sizes, and accessories, so they can be easily specified accordin...

View Detail -

Sintered Stainless Steel Porous Metal Powder Filter Used For Gas Sensor Sampling Probe

Products Description A pneumatic component for a sampling of gas sensors, which is used to reduce pressure fluctuations The gas sampling head is a special g...

View Detail -

Sintered Porous Metal Stainless Steel Filter Tube for Fiber Optic Collimator HENGKO

Product Describe porous metal cartridges can be customized for a wide variety of applications and specifications and can be attached to metallic and non-meta...

View Detail -

OEM Porous Metal Stainless Steel Filter Vacuum Electron Beam Welding Sintered Metal Fil...

Product Describe Electron beam welding is used in many industries such as aerospace, atomic energy, automotive, and electrical and electric instrumentation b...

View Detail -

Incubator temperature and humidity controller sintered porous metal stainless steel 316...

HENGKO stainless steel sensor shell is made by sintering 316L powder material in high temperatures. They have been widely used in environmental protection, p...

View Detail -

316L Stainless Steel Porous Metal Media 1/4″ and 1/2″ Face Seal Gasket Filter for Extre...

HENGKO manufactures porous metal media in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and config...

View Detail -

Sintered Metal Stainless Steel Porous Mesh Filters for in High Pressures Environments

Hengko’s food-grade textile filters are primarily manufactured in the form of cups, threaded cups, discs, and extended area packs. These filters are primaril...

View Detail -

OEM high purity porous metal 316L chamber diffusers and filters

HENGKO OEM Gas Chamber Diffusers provide uniform and laminar gas flows without disturbing particles in the chamber. These diffusers also remove particles fro...

View Detail -

Porous Metal Filter For Culture Vessel OEM and Custom

High-purity filters and spargers are specially designed to meet strict requirements for the removal of particles in process gases in, for example, semiconduc...

View Detail -

Gas Diffusion Layers Sheet for MEAs, stainless steel porous metal sintered / wire mesh ...

HENGKO stainless steel filter plates are made by sintering 316L powder material or multilayer stainless steel wire mesh at high temperatures. They have been ...

View Detail -

3D Printed porous metal filter OEM filtration & flow control designs for medical d...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Stainless steel harsh environment filter (male thread sintered porous metal filter) for...

Product Features Remove liquids and solids from gas samples Remove solids and gas bubbles from liquid samples Coalesce and separate two liquid phases Filer s...

View Detail -

Catalyst porous metal filter extreme environment working Gas Sample Probe, high flow fi...

Gas and liquid sample analyzer filters protect analyzers from sample impurities by removing soilds and liquids from gases with 99.99999+% efficiency at 0.1 m...

View Detail -

custom 5 60 micron gas pressure flow meter 316L metal stainless steel sintered porous f...

_<img src="https://www.hengko.com/uploads/HTB1WxA_aUvrK1RjSspc762zSXXaK.png" width="750" height="980" usemap="#HENGKO" bord...

View Detail -

316L stainless steel porous metal straight filter tube shaped sparging assemblies

Sintered air stone diffusers are often used for porous gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through t...

View Detail

1. Introduction to Porous Metal Filters

(What They Are & Why They Are Critical)

Porous metal filters—also known as sintered metal filters, porous stainless steel filters,

or sintered porous elements—are engineered metal components containing a highly uniform

3-dimensional network of interconnected pores.

These pores are created by vacuum sintering metal powders at controlled temperatures, forming a rigid,

high-strength, permeable structure capable of precise filtration and flow control.

Because of their mechanical strength, corrosion resistance, stability, and reusability,

porous metal filters are widely used in:

- Semiconductor equipment (CVD / PVD / Etch / Diffusion / ALD)

- Gas analyzers and gas detection instruments

- Vacuum KF / VCR / ISO flange systems

- Fuel gas & hydrogen purification

- Environmental monitoring sensors

- Chemical and petrochemical systems

- Pharmaceutical and bioprocessing industries

- High-temperature gas/liquid filtration

- Sparging, aeration, and diffusion systems

- Flow equalization and flame arresting

A porous metal filter provides consistent and accurate filtration performance,

even under harsh environments involving high temperature, high pressure, corrosive chemicals,

cyclic loads, or aggressive gases.

2. Why Choose HENGKO as Your Porous Metal Filter OEM Factory?

HENGKO is a professional manufacturer specializing in sintered porous metal filters,

porous stainless-steel filter elements, sintered tubes/discs, and custom OEM

porous components used by global sensor brands and industrial system builders.

With more than 15+ years of porous metal R&D and OEM experience, we provide:

✔ Full-range OEM / ODM services

- Custom micron size (0.1–120 µm)

- Custom porosity (10–55%)

- Custom shapes: disc / cup / cone / tube / cartridge / blocks

- Custom materials: 316L / Bronze / Titanium / Nickel alloys

- CNC precision machining (NPT / BSP / UNF / VCR / KF / Flange)

- Laser welding and metal sealing

- Logo engraving & private labeling

- Prototyping + mass production

✔ Advanced vacuum sintering technology

- Ensures stable pore size distribution, high mechanical strength,

and consistent flow performance.

✔ Strong technical support

- Engineers with expertise in gas dynamics, filtration mechanics, metallic materials,

and sensor design.

✔ Complete QC system

Particle size analysis, porosity testing, helium leak detection, pressure resistance testing,

and chemical compatibility evaluation.

✔ High repeat-order rate from industrial manufacturers

- We supply porous metal filters to companies in:

semiconductor, instrumentation, environmental monitoring, chemical engineering,

gas equipment, petrochemical, and laboratory industries.

HENGKO is not a trading company

—we are a direct OEM factory, ensuring stable-quality

production and competitive pricing.

3. How Porous Metal Filters Work

(Engineering-Level Explanation)

Porous metal filters operate through a complex but highly

controllable mechanism combining:

3.1 Mechanical Filtration (Primary Mechanism)

Particles larger than the pore size are mechanically intercepted and

retained on or within the 3-D porous structure.

3.2 Depth Filtration

Unlike mesh screens, porous metal filters have thick porous pathways,

allowing particles to become trapped within the depth of the material.

3.3 Diffusion & Inertial Interception

At smaller micron levels (0.1–5 µm), particle capture relies on

Brownian motion and inertial collision.

3.4 Laminar Flow Equalization

Porous metals generate extremely uniform laminar flow, ideal for:

- Gas analyzers

- Pressure equalization

- Emission detection

- Flow control devices

3.5 Sparging & Aeration

When used for sparging/diffusion, pressurized gas passes through micro-pores,

creating fine and uniform microbubbles.

4. Material Options for Porous Metal Filters

(Full Technical Comparison)

HENGKO offers multiple metal materials depending on application, chemical environment,

cost, and performance requirements.

Here is a detailed comparison table to help you easily review and compare different porous metal filter materials:

| Material | Key Advantages | Best Applications |

|

316L Stainless Steel (Most Popular) |

• High mechanical strength | • Gas detection systems |

| • Excellent corrosion resistance | • Vacuum KF / VCR interfaces | |

| • Withstands 200–500°C | • Chemical filtration | |

| • Suitable for most gases & liquids | • Sensor protection | |

| • Cost-effective & stable | • Hydrogen / nitrogen / compressed air systems | |

| • Ideal for general industrial filtration | ||

| Bronze Porous Metal Filters | • Lower cost | • Pneumatic systems |

| • Moderate mechanical strength | • Silencers | |

| • Good filtration uniformity | • Air exhaust filtration | |

| • Suitable for general air filtration | ||

|

Titanium Porous Filters (Ultra High Performance) |

• Extreme corrosion resistance | • Semiconductor gas filtration |

| • Biocompatibility | • Biomedical industry | |

| • High temperature resistance up to 600°C | • High-purity chemical processes | |

| • Ultra-clean, ideal for critical processes | ||

|

Nickel Alloy / Monel / Inconel Porous Filters |

• Exceptional corrosion resistance | • Harsh chemical processes |

| • Withstands highly oxidative or acidic gases | • High-temperature reactors | |

| • High mechanical strength under cyclic load | • Corrosive gas filtration |

5. Manufacturing Technology:

How HENGKO Produces High-Performance Porous Metal Filters

Our production combines advanced powder metallurgy, controlled sintering, precision machining, and high-level quality control.

6. Technical Specifications of Porous Metal Filters

Porous metal filters must meet strict engineering parameters to ensure stable performance in high-pressure, high-temperature,

or corrosive environments. Below is a detailed technical specification list applicable to HENGKO’s sintered porous components.

so you can know details of each materials of porous metal can use.

6.1 General Technical Specifications

| Specification | Value / Range | Notes |

|---|---|---|

| Micron Rating | 0.1–100 µm | Narrow PSD, stable pore structure |

| Porosity | 10–55% | Adjustable based on flow/pressure requirements |

| Thickness | 0.2–10 mm | Custom available |

| Max Pressure Resistance | Up to 30 MPa | Depends on shape & thickness |

| Temperature Range | -200°C to 600°C | Per material (316L, Ti, Ni alloy) |

| Flow Rate | Custom tested based on API/ISO curves | Flow data available |

| Chemical Resistance | Excellent | Ideal for gas/liquid corrosive media |

| Cleaning Method | Ultrasonic, back-flush, chemical wash | Reusable |

| Materials | 316L / Bronze / Titanium / Nickel Alloy | OEM material selection |

| Shape Options | Tube, disc, cup, cone, cartridge, block | Fully customizable |

| Welding | Laser welding / TIG welding | Leak-proof |

| Machining | CNC precision up to ±0.02 mm | For threads & flanges |

6.2 Mechanical Strength Specifications

| Property | Typical Value |

|---|---|

| Compression Strength | >150–300 MPa (316L) |

| Tensile Strength | 500–600 MPa (varies by material) |

| Burst Pressure | 5–30 MPa (depends on OD/ID/thickness) |

| Poisson Ratio | 0.25–0.30 |

| Young’s Modulus | 120–160 GPa |

6.3 Filtration Performance Specifications

| Parameter | Description |

|---|---|

| Pore Size Distribution (PSD) | Narrow distribution ensures predictable filtration |

| Depth Filtration | Multi-layer internal particle capture |

| Flow Uniformity | Highly stable laminar flow |

| Gas Permeability | High permeability even in 1–2 µm grades |

| Liquid Filtration Efficiency | 95–99.9% depending on micron size |

6.4 Chemical Compatibility Chart (Short Version)

| Medium | 316L | Titanium | Nickel Alloy | Bronze |

|---|---|---|---|---|

| Acids | Good | Excellent | Excellent | Poor |

| Alkalis | Good | Excellent | Excellent | Medium |

| Organic Solvents | Excellent | Excellent | Excellent | Good |

| High Purity Water | Good | Excellent | Good | Poor |

| Oxidizing Gases | Medium | Excellent | Excellent | Poor |

| Corrosive Gases | Medium | Excellent | Excellent | Poor |

7. Product Selection Guide

(Micron • Material • Shape • Application)

Here we will list some advices based on your different pore size, condition, shape and

applications, you can check detail as following :

7.1 How to Choose Micron Rating

| Micron Size | Recommended Use |

|---|---|

| 0.1–0.5 µm | Ultra-fine gas filtration (semiconductor, lab analyzers) |

| 1–5 µm | Gas analyzers, flame arrestors, pressure equalizers |

| 10–20 µm | Sensor protection, gas sampling systems |

| 20–40 µm | General gas & liquid purification |

| 60–100 µm | Sparging, aeration, diffusion |

7.2 How to Choose Material

| Requirement | Recommended Material |

|---|---|

| High corrosion resistance | Titanium / Nickel Alloy |

| High temperature (400–600°C) | Titanium / Nickel Alloy |

| Cost-sensitive projects | 316L / Bronze |

| High purity applications | Titanium |

| Strong pressure & mechanical load | 316L / Nickel Alloy |

| Semiconductor gases | Titanium |

7.3 How to Choose Shape

| Shape | Use Case |

|---|---|

| Disc | Gas sampling, inline filtration |

| Tube / Cylindrical | Sparging, diffusion, pressure equalization |

| Cup / Cone | Sensor protection, flame arrestors |

| Cartridge | High flow industrial systems |

| Block / Plate | Chemical reactors, high-temperature filtration |

7.4 How to Choose Based on Industry

| Industry | Recommended Filter Type |

|---|---|

| Semiconductor | Titanium porous tube/disc, 0.1–5 µm |

| Gas analyzers | 316L tube/disc, 1–20 µm |

| Vacuum systems | 316L KF/VCR filters |

| Chemical plants | Ni-alloy cartridges |

| Environmental monitoring | 316L sensor housings |

| Sparging systems | 20–100 µm porous tubes |

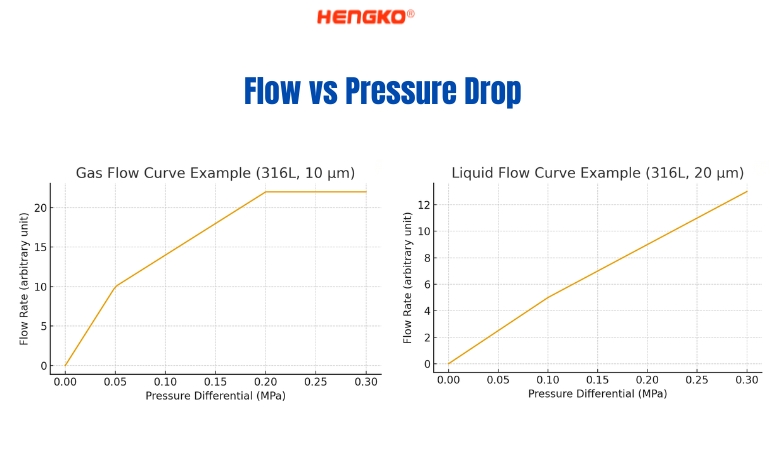

8. Flow Rate & Pressure Drop Curves

Here are generalized flow characteristics based on typical HENGKO porous metal filter structures (actual curve depends on OD/ID/thickness/micron grade):

8.1 Gas Flow Curve (Example: 316L, 10 µm)

- Flow increases linearly at low pressure differentials

- Enters laminar regime at 0.05–0.2 MPa

- Stable plateau ensures no pulsation

- Suitable for gas detection, sampling systems

8.2 Liquid Flow Curve (Example: 316L, 20 µm)

- Higher pressure required due to viscosity

- High stability under temperature fluctuation

- Excellent for alcohols, hydrocarbons, solvents

9. Product Models

(Disc • Tube • Cone • Cartridge • Sensor Housing)

9.1 Porous Metal Disc Filters

Used in gas analyzers, vacuum systems, sampling, and sensor protection.

| Parameter | Range |

|---|---|

| OD | 5–120 mm |

| Thickness | 0.3–5 mm |

| Micron Rating | 0.1–100 µm |

| Material | 316L / Ti / Bronze / Ni alloy |

9.2 Porous Metal Tubes (Cylindrical Filters)

Ideal for sparging, aeration, flow equalization, and high-pressure filtration.

| Parameter | Range |

|---|---|

| OD | 3–80 mm |

| Length | 10–1200 mm |

| Wall Thickness | 0.5–3 mm |

| Micron Rating | 0.2–60 µm |

9.3 Porous Metal Cone / Cup Filters

Used in flame arrestors, sensor housings, gas detectors.

| Parameter | Range |

|---|---|

| OD | 3–50 mm |

| Height | 5–60 mm |

| Micron | 1–50 µm |

9.4 Porous Metal Cartridges

Used in chemical plants, reactors, compressed gas filtration.

| Parameter | Range |

|---|---|

| OD | 20–80 mm |

| Length | 50–1000 mm |

| End Caps | NPT / BSP / Flange / Custom |

| Micron | 1–40 µm |

9.5 Porous Metal Sensor Housing Filters

Used in temperature, humidity, dew point, and gas sensors.

| Parameter | Range |

|---|---|

| Thread | M10 / M12 / 1/4 NPT / Custom |

| Micron | 1–20 µm |

| Material | 316L / Nickel Alloy |

| Housing Type | Cup / Tube / Customized |

10. Application Industries

Porous metal filters are used across 50+ industrial sectors.

10.1 Semiconductor Manufacturing

- CVD

- PVD

- Etching

- ALD

- Diffusion furnaces

- High-purity gas lines

Titanium porous metal filters are preferred due to purity & corrosion resistance.

10.2 Gas Analysis & Detection

Used in:

- CO₂ analyzer

- O₂ / H₂ / CH₄ sensors

- FTIR instruments

- Portable gas detectors

Provides stable flow and prevents particle contamination.

10.3 Chemical Processing Plants

Used for:

- High-temperature reactors

- Solvent filtration

- Catalyst protection

- Corrosive gas filtration

Nickel alloy is ideal here.

10.4 Vacuum & VCR / KF Systems

- KF16 / KF25 / KF40 porous protection filters

- VCR gasket filters

- Vacuum chambers

316L stainless steel is preferred.

10.5 Environmental Monitoring

- Air quality sensors

- Meteorological stations

- Water testing systems

Porous metal prevents dust, insects, and droplets from entering sensors.

10.6 Sparging & Aeration Systems

For mixing gases into liquids (bioreactors, chemical reactors, labs).

- Fine bubble diffusion

- Highly uniform distribution

- No clogging

Porous metal tubes (20–100 µm) work best.

11. Why Customers Switch to HENGKO

Porous metal filters are used across semiconductor, petrochemical, environmental, gas analysis,

and industrial automation systems.

Many global companies use proprietary porous metal elements, but HENGKO provides

full compatibility and cross-reference replacements with equal or superior performance.

| Feature | MOTT / Ames / Others | HENGKO |

|---|---|---|

| OEM Customization | Limited | Unlimited (full OEM/ODM) |

| Delivery Time | Slow | Fast, flexible |

| MOQ | Medium–High | Low MOQ available |

| Cost | Higher | More cost-effective |

| Engineering Support | Strong | Strong + Faster + Flexible |

| Sensor Housing OEM | Rare | Specialized |

11.1 OEM / ODM Custom Service

OEM/ODM is the core of HENGKO’s porous metal business.

We support full customization, including:

Customization Parameters

| Custom Parameter | Description |

|---|---|

| Micron Rating | 0.1–100 µm (precise PSD control) |

| Material | 316L / Bronze / Titanium / Monel / Inconel |

| Dimensions | OD/ID/Length/Thickness totally customizable |

| Shapes | Disc, tube, cone, cup, cartridge, block |

| Thread Interface | NPT, BSP, UNF, M10/M12, or custom |

| Surface Finish | Electropolish, passivation, polishing |

| Welding | Laser welding, TIG welding |

| Pore Structure | Controlled porosity (10–55%) |

| Flow Performance | Designed according to pressure drop targets |

| Logo / Labeling | OEM print, laser marking |

| Packaging | Industrial PE, dust-proof, cleanroom options |

11.2 OEM Process Flow

1.Requirement Collection

Micron rating / material / drawings / environment / flow target

2.Design & Simulation

Flow rate, porosity distribution, mechanical load analysis

3.Prototype Fabrication

Small-batch samples (1–20 pcs)

4.Testing & Validation

Pressure, chemical, and dimensional accuracy tests

5.Mass Production

Vacuum sintering + CNC + welding + QC

6.Packaging & Shipment

Industrial export packaging

FAQ – Common Engineering Questions

1. What is the standard micron rating range of porous metal filter ?

HENGKO porous metal filters are available from 0.1 µm to 100 µm, with narrow PSD for stable, repeatable filtration performance.

2. Can porous metal filters be cleaned and reused?

Yes. They can be cleaned by:

*Back-flushing

*Ultrasonic cleaning

*Chemical cleaning (acid/alkali depending on material)

*High-temperature baking

This makes them highly cost-effective compared to disposable filters.

3. What is the maximum temperature resistance?

| Material | Max Temperature |

|---|---|

| 316L | 400–500°C |

| Titanium | Up to 600°C |

| Nickel Alloy | Up to 600°C |

| Bronze | ~250°C |

4.What pressure can porous metal filters withstand?

Depending on OD/ID and thickness, they can withstand up to:

*10–30 MPa (316L tubes)

*5–20 MPa (discs and cones)

Special high-pressure models available on request.

5.Are porous metal filters suitable for corrosive gases or liquids?

Yes.

316L is suitable for general industrial chemicals.

Titanium and Nickel alloys are recommended for:

*Acidic gases

*Oxidative gases

*Corrosive liquids

*High-purity chemicals

6.Can you manufacture based on drawings or samples?

Absolutely.

We accept:

*2D/3D CAD files

*STEP/IGES

*Physical samples

*Reverse engineering requirements

7.What is the typical lead time?

*Samples: 7–12 days

*Mass production: 15–25 days

*Large OEM orders: negotiated based on volume

8.Do you provide OEM branding and labels?

Yes, we support:

*Laser-etched logos

*Private label packaging

*OEM barcode printing

9.What industries use porous metal filters?

*Semiconductor

*Gas analysis

*Chemical plants

*Environmental monitoring

*Fuel & hydrogen systems

*Vacuum systems

*Laboratory & biotech

10.How can I get a technical quote?

You can email your project details directly to: ka@hengko.com

Ready to Start Your Porous Metal Filter Project?

We provide full OEM/ODM engineering support, from micron rating design to complete sintered metal assembly.

Whether you need 316L, Titanium, or Nickel alloy porous filters, our technical team can help you build the right solution.

Email us your requirements: ka@hengko.com

- WhatsApp/WeChat support available upon request

- Drawings • Specs • Samples • Customized Designs

HENGKO – Your Trusted Porous Metal Filter OEM Factory