-

Custom 35 50 microns fuel filter sintered bronze filter disc disk for heavy duty and in...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

Metal powder sintered porous porosity bronze 316 stainless steel micro filters discs

The bronze porous sintered filter element is made of copper alloy powder sintered at high temperature. It has high filtration precision, good air permeabili...

View Detail -

Personal customization 15 45 90 micron powder sintered brass bronze porous metal oil fi...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

porous metal filter disc square strainer micron sintered bronze filter sheet

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

sintered metal filter disc for wastewater treatment, 5 20 micron 304 316L stainless ste...

Depth filter sheets are used to remove particles from liquids. This means that liquids can be clear-, fine- or sterile-filtered. Filter sheets are ideal for ...

View Detail -

Sintered filter parts and micron sintered porous metal bronze filter disc

Product Describe HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characterist...

View Detail -

3 5 18 30 60 90 Micron porous sintered bronze air filter disc for industrial filtration...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail -

R=11/30 mm diameter 20 micron sintered multilayer bronze stainless steel sintered filte...

HENGKO manufactures filter elements in a broad range of materials, sizes, and fittings so they can be easily specified with the characteristics and configura...

View Detail

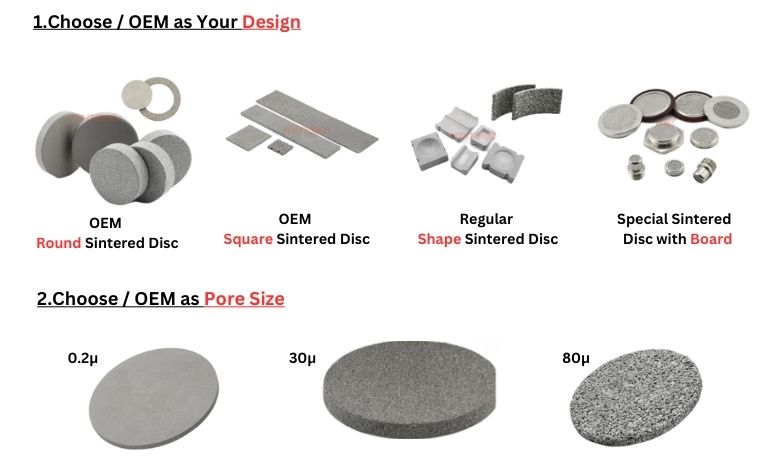

Types of Sintered Filter Disc

When you choose disc filter, special metal disc filter, maybe you also need to face the

first question, what type of sintered filter disc i need to choose ? then please check details

as following about types of sintered filter disc, hope it will be helpful for your choosing.

1. Application

Sintered filter discs are a type of filter made from metal powder that has been compressed

and heated to form a porous disc. They are used in a variety of applications, including:

* Chemical and pharmaceutical processing

* Food and beverage processing

* Oil and gas production

* Water treatment

* Air filtration

There are several different types of sintered filter discs, each with its own advantages and

disadvantages. The most common types include:

1. Sintered metal fiber discs:

These discs are made from a mesh of metal fibers that have been sintered together. They offer

high flow rates and good particle retention, but they can be susceptible to clogging.

2. Sintered wire mesh discs:

These discs are made from a layer of wire mesh that has been sintered to a support disc. They are less

susceptible to clogging than sintered metal fiber discs, but they have lower flow rates.

3. Metal powder filters:

These discs are made from a mixture of metal powders that have been sintered together. These filter

can offer a wide range of pore sizes and can be customized to meet specific filtration requirements.

The type of sintered filter disc that is right for you will depend on the specific application.

Some factors to consider include:

* The type of fluid being filtered

* The particle size of the contaminants

* The desired flow rate

* The pressure drop

* The cost

Sintered filter discs are a versatile and effective filtration solution. They offer a wide range of pore sizes

and can be used in a variety of applications. When choosing a sintered filter disc, it is important to consider

the specific needs of your application.

Main Features of Sintered Filter Disc

Here, we list some main features of sintered dis filters, hope this will be helpful for you

to understand more for the products

1. High filtration efficiency:

Sintered discs are highly effective at removing impurities and contaminants from liquids or gases, making them ideal for a wide range of industrial and commercial applications.

2. Durable and long-lasting:

The sintering process creates a strong and durable filter medium that can withstand harsh environments and repeated use.

3. Highly porous:

The porous structure of sintered filter discs allows for high flow rates and efficient filtration.

4. Chemical and corrosion-resistant:

Sintered discs filter are resistant to many chemicals and corrosive substances, making them ideal for use in demanding environments.

5. Versatile and customizable:

Sintered filter discs can be manufactured in a wide range of sizes, shapes, and designs to meet the specific needs of a variety of applications.

6. Easy to clean and maintain:

Sintered disc filters can be easily cleaned and maintained, allowing for longer service life and improved performance over time.

Overall, sintered filter discs offer a combination of effective filtration, durability, and versatility that make them an essential component for many industries and applications.

What you should care when OEM Sintered Filter Disc ?

When embarking on an Original Equipment Manufacturer (OEM) project for Sintered Filter Discs for your filtration system, several key considerations should be kept in mind:

1. Material Selection:

Understand the type of material suitable for your application. Different metals offer different levels of corrosion resistance, durability, and filtration efficiency.

2. Filter Size and Shape:

Consider the size and shape of the filter disc required. This depends on the capacity and design of your filtration system.

3. Porosity and Permeability:

Define the desired porosity and permeability of the filter disc. This affects the filtration speed and efficiency.

4. Operating Conditions:

Consider the conditions under which the filter disc will operate, such as temperature, pressure, and type of media (liquid or gas) to be filtered.

5. Regulatory Standards:

Ensure the filters meet relevant industry standards and regulations, particularly in industries like pharmaceuticals or food and beverage.

6. Manufacturer’s Capabilities:

Verify the manufacturer’s ability to meet your specifications, their experience, quality control measures, and reputation in the market.

7. Post-Sale Support:

Consider if the manufacturer provides support after the sale, such as technical assistance or warranty.

Careful attention to these points can help ensure a successful OEM Sintered Filter Disc project for your filtration system.

Applications :

Sintered filter discs are versatile components that can be used in a variety of applications. Here are some project and application examples using sintered filter discs:

Water Filtration:

Sintered filter discs are commonly used in water filtration systems to remove impurities and contaminants from drinking water. Discs are made from a variety of materials, including stainless steel and porous plastic, and can be customized to meet specific filtration needs.

Chemical Processing:

Sintered disc filter are also used in chemical processing to filter and separate liquids and gases. They are used to remove impurities from chemical solutions, to separate one substance from another, and to control the flow of liquids and gases.

Medical Devices:

Sintered filter discs are used in a variety of medical devices including surgical instruments and drug delivery systems. They are used to filter out bacteria and other contaminants from medical solutions, and to control the flow of liquids and gases in medical devices.

Air Filtration:

Sintered filter discs can be used to filter and purify air in a variety of environments including homes, commercial buildings and industrial facilities. Discs can be customized to remove specific contaminants such as dust, pollen and mold spores.

OIL AND GAS INDUSTRY:

Sintered disc filters are used in the oil and gas industry to filter and separate liquids and gases. They can be used to remove impurities from oil and gas solutions, to separate one substance from another, and to control the flow of liquids and gases.

Food and Beverage Industry:

Sintered filter discs are used in the food and beverage industry to filter and purify liquids such as fruit juices, beer and wine. They can be used to remove impurities and contaminants from liquids and to control the flow of liquids during production.

These are just a few examples of applications and projects using sintered filter discs. With their versatility and customization options, sintered filters can be used in a wide range of industries and environments.

Electronics:

Sintered discs can be used in electronics manufacturing to filter and purify liquids used in the production of electronic components such as semiconductors and circuit boards.

Automotive Industry:

Sintered filter discs can be used in the automotive industry to filter and purify fluids used in engines and transmissions, and to control the flow of air and fuel in engines.

Mining Industry:

Sintered disc filter are used in the mining industry to filter and separate liquids and gases such as water and methane from extracted minerals.

Aerospace industry:

Disc type filters can be used in the aerospace industry to filter and purify liquids and gases used in aircraft production and operation.

Environmental Remediation:

Sintered filter discs can be used in environmental remediation projects to filter and separate contaminants from soil and water samples.

These are just a few examples of the various applications and projects that use sintered filter discs. With their high durability, versatility and customizability, sintered filter discs can become an essential part in a variety of industries and environments.

FAQ about sintered filter discs

Sintered filter discs are versatile components used in a variety of applications across many different industries. Here are some frequently asked questions about sintered filters and their use:

1. What is a sintered filter?

A sintered filter disc is a filter made by compressing metal or plastic powders together and heating them until they bond.

The resulting material is then processed into the desired shape and size.

2. What are the benefits of using sintered filters?

Sintered filter discs offer several advantages, including high durability, corrosion and temperature resistance, and the ability to be customized to meet specific filtration needs.

3. What material is the sintered filter made of?

Sintered filter discs are available in a variety of materials including stainless steel, bronze, nickel and porous plastic.

4. What are the applications of sintered filters?

Sintered filter discs are used in a wide variety of applications including water filtration, chemical processing, medical devices, air filtration, and the oil and gas industry.

5. What size and shape can the sintered filter be?

Sintered filter discs can be customized to meet specific size and shape requirements, making them suitable for a variety of applications.

6. What is the filtration grade of the sintered filter disc?

The filtration rating of sintered filter discs depends on the size of the pores in the material. The pore size can vary from a few microns to hundreds of microns.

7. How to clean the sintered filter disc?

Sintered filter discs can be cleaned by soaking them in a cleaning solution, such as a mild acid or base solution, or by backwashing with water or air.

8. Can the sintered filter be reused?

Yes, sintered filter discs can be reused after cleaning and inspection to ensure they are still in good condition.

9. What is the service life of the sintered filter?

The service life of sintered filter discs depends on several factors, including the material of manufacture, application, and frequency of cleaning and inspection.

10. How to choose the right sintered filter disc for your application?

To select the proper sintered filter disc for your application, consider factors such as the material to be filtered, the size and shape requirements, and the desired filtration grade.

11. What is the difference between sintered filter and wire mesh filter?

Sintered disc filters are made from compressed metal or plastic powder, while wire mesh filters are made from woven or knitted wire. Sintered filter discs offer greater durability and custom filtration capabilities, while wire mesh filters are generally less expensive.

12. What is the difference between sintered filter disc and ceramic filter element?

Sintered disc filters are made from metal or plastic powder, while ceramic filters are made from fired clay or other ceramic materials. Ceramic filters offer high temperature and chemical resistance, while sintered filter discs offer greater durability and custom filtration capabilities.

13. Can sintered filters be used in high temperature applications?

Yes, sintered filters can be used in high temperature applications, depending on the material from which they are made and specific application requirements.

14. Why choose Sintered Filter Disc for your filtration system ?

Opting for a Sintered Filter Disc in your filtration system brings several advantages:

1. High Efficiency: Sintered filter discs have an excellent ability to filter out small particles from liquids or gases, ensuring a cleaner output.

2. Durability: The sintering process makes these filters exceptionally robust and resistant to wear and tear, extending their lifespan.

3. Versatility: These discs can be made in a wide range of sizes, shapes, and designs, making them suitable for a diverse array of applications.

4. Heat Resistance: The discs can withstand high temperatures, making them ideal for use in demanding industrial environments.

5. Reusable: Sintered filter discs can be cleaned and reused, making them a cost-effective solution.

6. Chemical Resistance: These filters resist corrosion from various chemicals, making them suitable for industries like pharmaceuticals, food and beverage, oil and gas, etc.

So, when you choose a Sintered Filter Disc, you're opting for an efficient, durable, and versatile component for your filtration system.

14. Can the sintered filter be used in a corrosive environment?

Yes, sintered filter discs can be made from materials with high corrosion resistance, making them suitable for use in corrosive environments.

15. Can sintered filter discs be used in food and beverage applications?

Yes, sintered filters can be made from food grade materials for food and beverage applications.

16. Can sintered filters be used in pharmaceutical applications?

Yes, sintered filters are widely used in pharmaceutical applications due to their excellent properties. These filters are recognized for their high mechanical strength, precise filtration accuracy, and good heat and corrosion resistance. In the pharmaceutical industry, they are often employed in applications such as gas and air filtration, liquid and solid separation, and sterile venting.

Specific applications in the pharmaceutical sector can include:

-

Sterile filtration: Sintered filters can be used to sterilize gases, liquids, and steam, ensuring a sterile environment during drug manufacturing.

-

Venting: Sintered filters, particularly those made from stainless steel or PTFE, can be used in pharmaceutical equipment for sterile venting purposes, ensuring contaminants are not introduced into the system.

-

Particle removal: Sintered filters can be used to remove particles from liquids or gases to ensure the purity and quality of pharmaceutical products.

-

Sparging and diffusion: In bioreactors, sintered filters can be used for sparging (introducing gases into liquids) or for diffusing air or oxygen into the medium.

It's important to note that for pharmaceutical applications, the filters must be made from materials that are compatible with the process and meet the stringent standards of the industry, such as FDA and USP Class VI requirements. Also, the pore size of the filter must be carefully selected to ensure it provides effective filtration for the specific application.

17. Can sintered filters be used in environmental remediation projects?

Yes, sintered filters can be used in environmental remediation projects to filter and separate contaminants from soil and water samples.

18. How are sintered filters made?

Sintered discs are made by compressing metal or plastic powders together and heating them until they bond. The resulting material is then processed into the desired shape and size.

19. Can the sintered filter be customized?

Yes, sintered disc filter can be customized to meet specific filtration requirements including size, shape and filtration class.

HENGKO offers a unique customization service for its sintered filters, ensuring that each product perfectly meets the specific

requirements and unique needs of its customers. Understanding that each filtration application can be different, they provide

options to tailor the size, shape, pore size, and material of their sintered filters, thereby offering solutions that are perfectly

suited to various industrial conditions and processes. With HENGKO, you are not just purchasing a product; you are procuring

a tailored solution designed to perform optimally in your specific application. Their commitment to customization demonstrates

their dedication to customer satisfaction and innovative filtration solutions.

20. Where can I buy sintered filters?

Sintered discs are available from a variety of suppliers, including industrial equipment suppliers and online retailers. When purchasing sintered filters, be sure to choose a reputable supplier that offers high-quality products and reliable customer service.

We hope these FAQs help answer some of your questions about sintered filter discs and their use.

If you have any other questions or would like more information,

You are welcome to send enquiry by email to ka@hengko.com to contact us.

Our team of experts can help you find the right solution for your needs.