High-Temp 200°C Humidity Transmitter for Industrial Ovens & Drying Systems by HENGKO HG808-T5N4

HENGKO HG808-T5N4 Series is a high-precision temperature and humidity transmitter specifically

designed for industrial high-temperature environments.

It integrates ultra-heat-resistant sensing elements within a robust cast-aluminum housing and

stainless-steel structure, ensuring exceptional long-term stability, accuracy, and corrosion resistance.

Engineered to perform reliably in extreme conditions, the HG808-T5N4 maintains precise measurement

at temperatures up to 190 °C.

Typical applications include high-temperature process control, industrial drying systems, flue gas and

combustion monitoring, and environmental test chambers.

Additionally, it is well-suited for corrosive gas monitoring in petrochemical and refinery processes,

offering dependable data even under aggressive gas compositions.

Key Features

*Split or pipeline probe design with exceptional anti-contamination and oil-resistant performance for reliable operation in demanding environments.

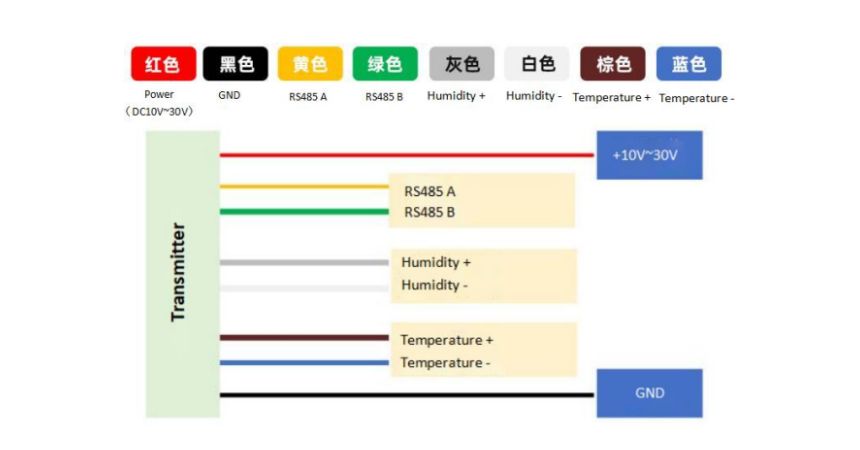

*Dual signal outputs: RS485 digital output and two high-resolution analog channels for flexible integration.

*High-precision resolution: 15-bit analog output and digital output with selectable 0.1 or 0.01 unit resolution.

*Flexible data access with support for both single-register and multi-register read functions.

*Anti-condensation protection to maintain stable sensor performance under high humidity conditions.

*Comprehensive digital output simultaneously provides dew point, relative humidity, temperature, and PPM readings.

*Standard Modbus RTU protocol ensures seamless connection with PLCs, DCS systems, and various industrial configuration software.

*Wide voltage input range (10–28 V) with built-in overcurrent, reverse polarity, and industrial-grade ESD protection for safe and durable operation.

Specification

Here’s a specification details for the HG808-T5N4 series Humidity Transmitter :

| Category | Specification |

|---|---|

| Temperature Range | -40 ~ +200°C |

| Humidity Range | 0 ~ 100% RH (Recommend < 95% RH) |

| Temperature Accuracy | ±0.1°C (@ 20°C) |

| Humidity Accuracy | ±2% RH (@ 20°C, 10 ~ 90% RH) |

| Power Supply | DC 10V ~ 28V |

| Power Consumption | < 0.5W |

| Analog Outputs | Humidity + Temperature: 4~20mA / 0-5V / 0-10V (one out of three) |

| RS485 Digital Output | Temperature, humidity, dew point, PPM (read simultaneously) |

| Resolution Ratio | 0.01°C / 0.1°C (optional) 0.01% RH / 0.1% RH (optional) |

| Baud Rate | 1200, 2400, 4800, 9600, 19200, 115200 (default: 9600 bps) |

| Acquisition Frequency | Fastest response: 1 second; other settings per PLC |

| Byte Format | 8 data bits, 1 stop bit, no check |

| Pressurization | 16 bar |

| Working Temperature | -20°C ~ +60°C, 0% RH ~ 95% RH (Non-condensation) |

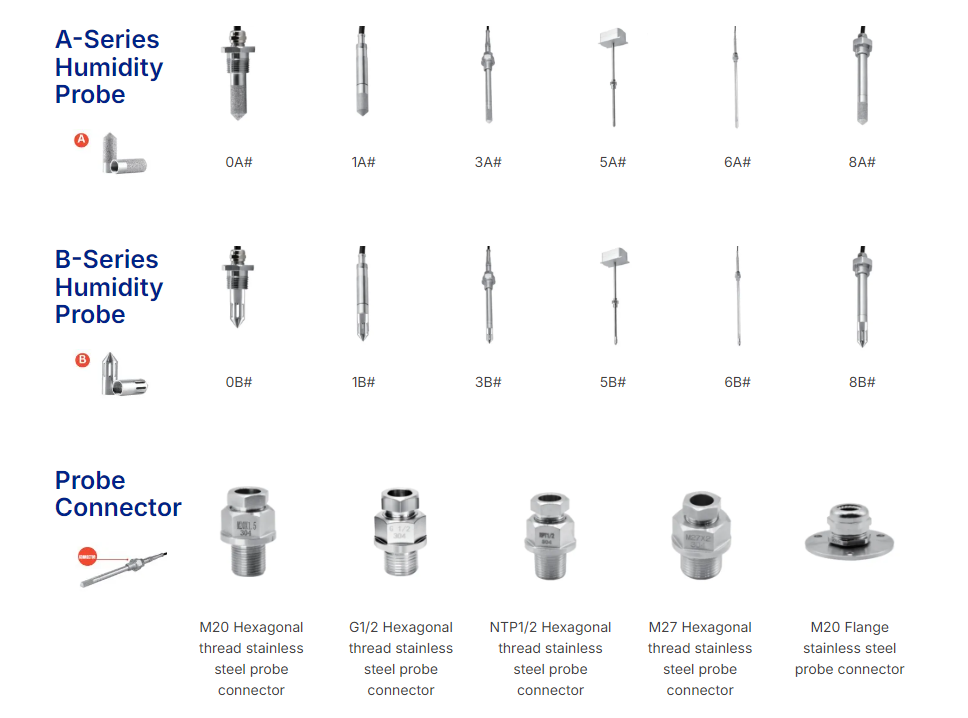

| Probe Type | Split type: Probe 3 –Split type :3A# / 3B# Probe 5 – Pipeline :5A# / 5B# Probe 6 – Split type :6A# / 6B# |

We offer 6 types of probes for the HG808 Humidity Transmitter, with each type available in both A and B versions,

providing a total of 12 probes for various application options.

Applications for Extreme Environments

Industrial operations often face extreme temperature and humidity challenges where standard transmitters fail to perform.

High-performance transmitters capable of operating above 200 °C or as low as –50 °C are essential for reliable monitoring and control across critical industries.

High-Temperature Applications (Above 200 °C)

*Industrial Ovens and Furnaces

Accurate temperature and humidity monitoring ensures consistent curing, drying, and heat-treating processes—vital for product quality in coating, ceramics, and metal processing.

*Power Generation

Measuring humidity in turbines and steam lines helps prevent corrosion and extend equipment life in thermal power plants.

*Chemical Processing

Precise environmental control in reactors, dryers, and pipelines enhances safety, reaction efficiency, and product purity.

*Semiconductor Manufacturing

Advanced transmitters maintain ultra-stable low-humidity conditions during photolithography, etching, and wafer processing, ensuring yield consistency.

*Glass Manufacturing

During melting, blowing, and annealing, stable temperature and humidity conditions are key to defect-free glass and uniform quality.

Low-Temperature Applications (Down to –50 °C)

*Cold Storage and Logistics

Continuous temperature and humidity monitoring in freezers and refrigerated warehouses preserves food quality and prevents spoilage.

*Cryogenic and LNG Systems

Reliable transmitters safeguard operations in superconductivity research and liquefied natural gas (LNG) handling, preventing ice formation and system failure.

*Climate and Environmental Monitoring

Deployed in Arctic regions or high-altitude stations, these sensors provide accurate data for meteorological and climate research.

*Aerospace and Defense Testing

Used for low-temperature simulation chambers, they verify material and component performance under real-world freezing conditions.

*Wind Turbine Icing Detection

Monitoring humidity and temperature on turbine blades helps detect icing early, avoiding efficiency loss and structural damage.

Send your message to us: