Micron replacement sintered stainless steel porous metal filter disc

Introducing HENGKO's High-Quality Stainless Steel Sintered Porous Metal Filters

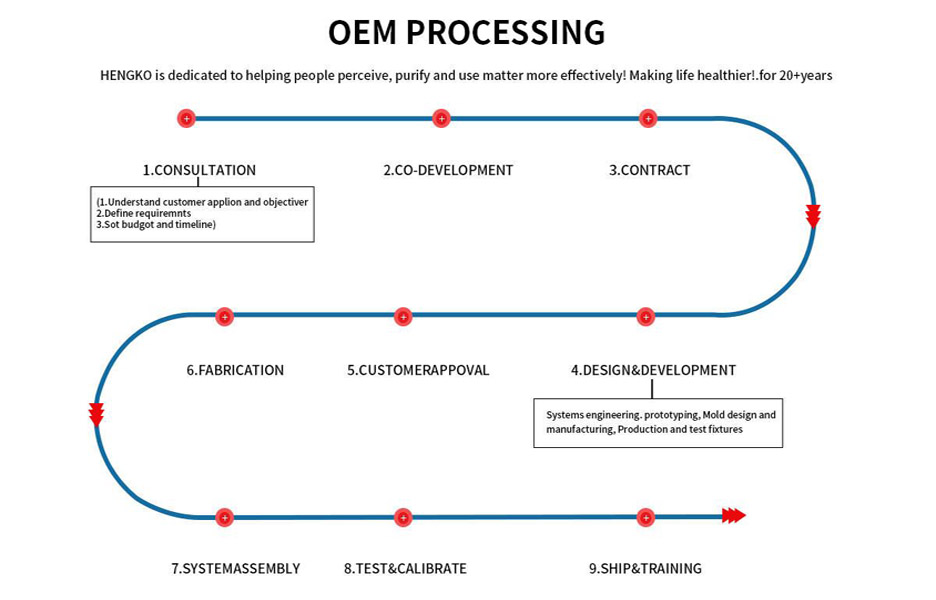

HENGKO is a leading manufacturer of stainless steel sintered porous metal filters that are designed to meet the varied needs of customers across diverse industries. These filters are available in a broad range of materials, sizes, and fittings to ensure that customers can easily specify the characteristics and configurations they require.

Our state-of-the-art manufacturing facility enables us to produce top-quality filters that are highly efficient and effective in filtering a wide range of media, including liquids, gases, and even steam. They are engineered to provide long-lasting performance, even under extreme operating conditions.

Customizable Features

We understand that each customer's filtration needs are unique, which is why we offer customizable features for our filters. Our expert team can incorporate custom features and create completely original filter element designs to meet specialized needs. This means that we can tailor our filters to meet your specific requirements, helping you achieve the best possible results.

Diverse Alloys

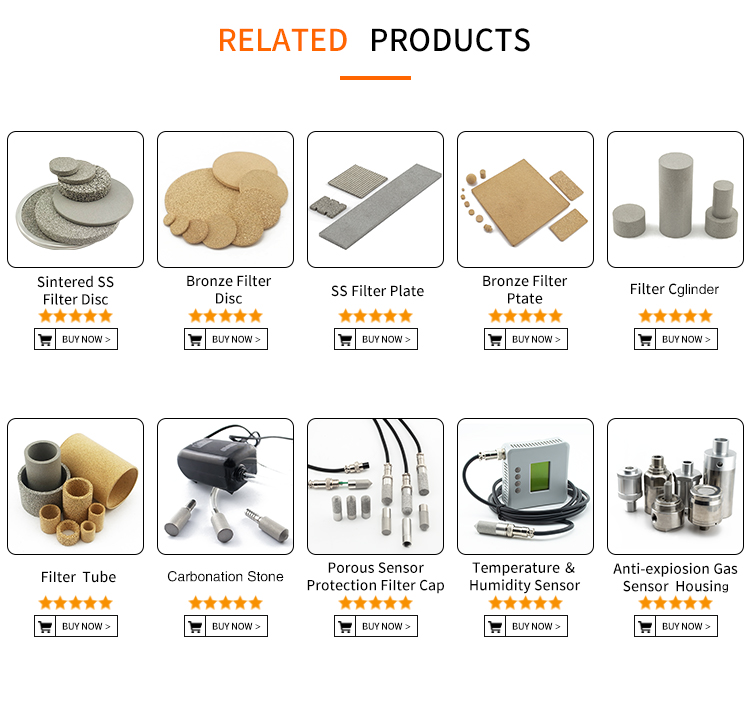

Our stainless steel sintered filter elements are available in a wide variety of different alloys, each with their own special benefits and application purposes. These include stainless steel 316L, titanium, nickel and even copper alloys. Each material has its own unique properties that make it ideal for specific applications.

Stainless Steel 316L - This alloy is highly resistant to corrosion and can withstand high temperatures and pressures. It is an ideal choice for applications in harsh environments.

Nickel - Nickel-based alloys have high corrosion resistance and are ideal for applications where the filter needs to withstand high temperatures.

Copper Alloys - Copper-based alloys are highly conductive and are ideal for applications where conductivity is a requirement.

Popular Choice

Our stainless steel sintered filters are a popular choice for customers due to their exceptional quality, durability, and performance. They are used in a wide variety of applications, including in the chemical, petrochemical, pharmaceutical, and food and beverage industries.

In conclusion, HENGKO's stainless steel sintered porous metal filters are a high-quality and customizable filtration solution that can be tailored to meet the specific needs of customers across diverse industries. Our filters come with a variety of different alloys, each with their own special benefits and application purposes. For those looking for a filtration solution that can handle even the toughest environments, choose HENGKO's stainless steel sintered porous metal filters.

Want more information or wouldl like to receive a quote?

Click the Online Service at the top right to contact our salespeople.

Micron replacement sintered stainless steel porous metal filter disc

1. Accurate pore size, uniform and even-distributed apertures. Pore size range: 0.1um to 120 microns;

2. Good breathability, fast gas & liquid flow rate and uniform divergence. it is far superior to other peer products with the optimization of special processes in HENGKO.

3. Good filtration dustproof and interception effect, high filtration efficiency. The pore size, speed of the flow and other performances can be customized as requested;

4. High supporting load capacity, no need to use other auxiliary supports, can be directly used as structural elements;

5. Stable structure, particles are tightly bound without migration, almost inseparable under harsh environment;

6. High fatigue strength and impact stress, high pressure resistant, suitable for applications with high pressure difference and flow rate. Sintered porous stainless steel filter elements for long-term usage under high pressure fluid (40mpa) conditions are available;

7. Resistance to high temperature and heat shock. HENGKO stainless steel filter elements can operate at 600 degrees celsius, can withstand high temperature even in oxidized atmospheres;

8. Excellent functions of separation and noise reduction as a result of special multidimensional honeycomb nested capillary structure;

9. Different from other peers, HENGKO stainless steel filter elements haven't been corroded in a variety of environments. The performances of anti-corrosion and rust-proof are close to dense stainless steel products;

10. More than 10K product sizes and types to choose from, customizable as needed for stainless steel filtering products with multiple complex structures;

11. Tiny diameter( 5-20 mm), the length for long filter tube can be up to 800 mm;

12. The processable dimension for plate filter can be up to L 800 * W 450 mm;

13. The maximum diameter for disc filter can be up to 450 mm;

14. Exquisite product appearance will upgrade your product level and image greatly as apparent parts;

15. A variety of cleaning methods are available, strong regeneration ability after reverse cleaning, long service life.