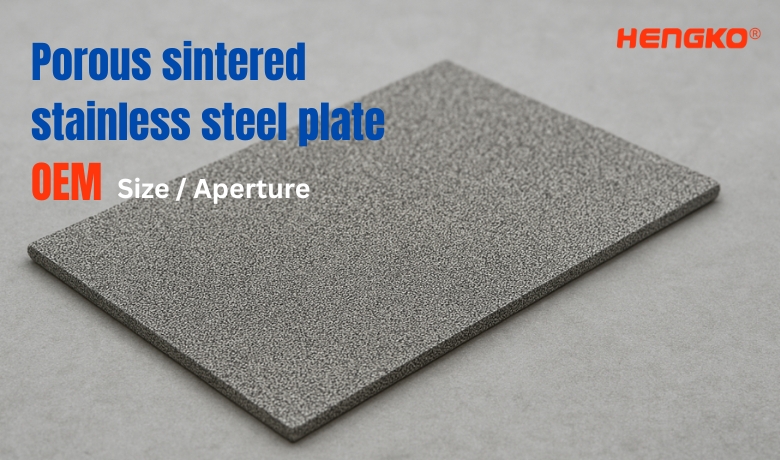

Porous Sintered Stainless Steel Plate – Key Features

1. High Mechanical Strength

*Manufactured through high-temperature sintering of metal powders.

*Retains structural integrity under pressure and high load conditions.

2. Excellent Heat & Corrosion Resistance

*Made from 304L or 316L stainless steel.

*Withstands harsh chemicals, acidic gases, and high-temperature environments (up to 600°C or more).

3. Uniform Pore Structure

*Precise control of pore size (typically 0.5 to 100 μm).

*Ensures consistent filtration, separation, or gas flow across the entire surface.

4. High Filtration Efficiency

*Effective for both solid-liquid and solid-gas separation.

*Captures fine particles while allowing clean fluid to pass.

5. Cleanable & Reusable

*Washable, backflushable, and resistant to clogging.

*Long service life compared to traditional filter materials.

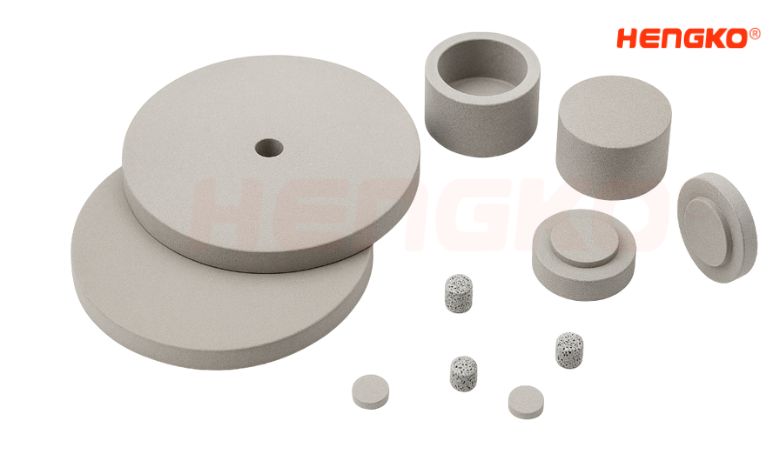

6. Customizable OEM Options

*Thickness: 1.5mm–20mm+

*Dimensions: cut to any shape (round, square, rectangular)

*Available with or without support mesh, flange, or welding options.

7. Applications

*Gas dispersion (spargers, diffusers)

*Solvent and chemical filtration

*Air/liquid purification in food, pharma, semiconductor, and petrochemical industries

*Flow control and flame arrestors

Applications & Requirements of Porous Sintered Stainless Steel Plates

| Application | Industry | Key Requirements |

|---|---|---|

| Gas Diffusion / Sparging | Chemical, Biotech, Food | - Uniform pore size (1–20 μm) - High air/gas flow - Corrosion resistance |

| Liquid Filtration (Solvents, Water) | Pharmaceutical, Electronics | - Precise pore control (0.5–10 μm) - High dirt-holding capacity - Reusability |

| Steam Filtration / Sterile Air | Pharmaceutical, Beverage | - Heat resistance up to 600°C - 100% stainless steel - Fine filtration (0.2–1 μm) |

| Dust Collection / Solid Separation | Petrochemical, Cement | - High mechanical strength - Anti-clogging - Easy backflush or ultrasonic cleaning |

| Flame Arrestor / Explosion Barrier | Gas, Mining, Oil | - High thermal conductivity - Specific porosity for pressure relief - Safety-certified |

| Flow Restrictors / Equalizers | Medical, Aerospace | - Stable flow rate - Precision thickness (≤1.5 mm) - Smooth surface finish |

| Electrochemical Electrode Support | Fuel Cell, Battery | - Conductive structure - Custom shapes - Thin profile with high porosity |

| Vacuum & Degassing Plates | Semiconductor, Coating | - Vacuum-compatible material - Ultra-fine pore size - Flatness & dimensional precision |

| Catalyst Carrier / Support | Refinery, Energy | - Thermal stability - High surface area - Chemically inert or catalytically active options |

Looking a Custom Solution for Your Project?

Whether you need precision pore sizes, unique shapes, or high-performance plates for extreme conditions

— HENGKO delivers tailored porous sintered stainless steel plate solutions to meet your exact requirements.

✅ OEM Sizes & Shapes

✅ Wide Range of Pore Sizes (0.2–100 μm)

✅ Fast Prototyping & Global Shipping

✅ Trusted by 1,000+ Industrial Clients Worldwide

Contact HENGKO Today to Get a Free Quote or Technical Consultation!

Email: ka@hengko.com

Send your message to us: