Oxygenation Wand - Sintered beer brewing SFW stainless steel 316L porous In-Line wortInline aeration/ carbonation diffusion stone oxygenation system for Homebrew – HENGKO

Oxygenation Wand - Sintered beer brewing SFW stainless steel 316L porous In-Line wortInline aeration/ carbonation diffusion stone oxygenation system for Homebrew – HENGKO Detail:

Sintered air stone diffusers are often used for porouse gas injecting. They have different pore sizes(0.5um to 100um) allowing small bubbles to flow through it. They can be used for gas transfer aeration, generating high volumes of fine,uniform bubbles often used for the treatment of wasewater, volatile stripping and steam injection. With greater gas and liquid contact area, the time and volume required to dissolve gas into liquid is reduced. This is accomplished by reducing the bubble size, which creates many tiny, slow moving bubbles that result in a large increase in absorption.

| Product Name | Specification |

| SFW11 | D1/2''*H16'' .5um with 3/16'' wand |

| SFW12 | D1/2''*H16'' 2um with 3/16'' wand |

| SFW21 | D1/2''*H26'' .5um with 3/16'' wand |

| SFW22 | D1/2''*H26'' 2um with 3/16'' wand |

| SFW31 | D1/2''*H36'' .5um with 3/16'' wand |

| SFW32 | D1/2''*H36'' 2um with 3/16'' wand |

Sintered beer brewing SFW stainless steel 316L porous In-Line wortInline aeration/ carbonation diffusion stone oxygenation system for Homebrew

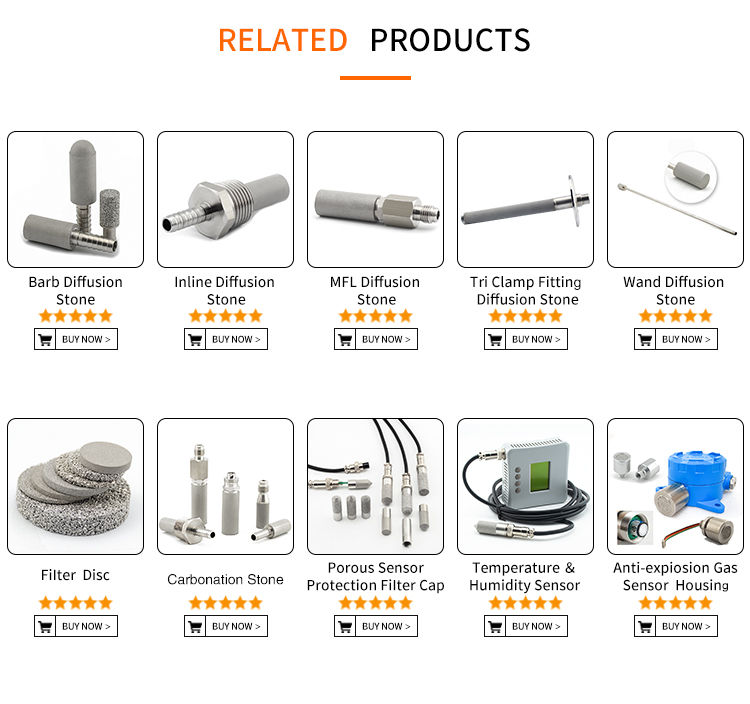

Related Products

Product detail pictures:

Related Product Guide:

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Oxygenation Wand - Sintered beer brewing SFW stainless steel 316L porous In-Line wortInline aeration/ carbonation diffusion stone oxygenation system for Homebrew – HENGKO, The product will supply to all over the world, such as: San Francisco, Maldives, Barbados, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.