What is Sintered Stainless Steel Filter Mesh

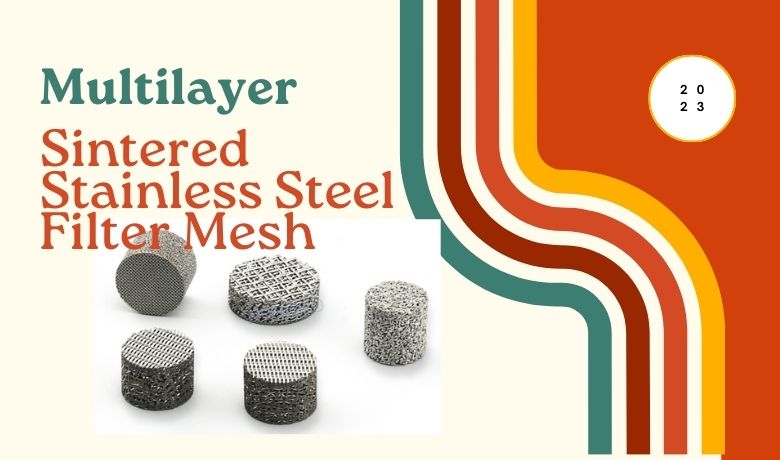

Sintered stainless steel filter mesh is a new filtration material with high mechanical strength and overall rigidity which is made of multilayer wire woven mesh through special lamination pressing and vacuum sintering. Not only it deals with the low strength, the poor rigidity and an unstable mesh shape of common metal mesh, but also reasonable matching and design to the material pore size, penetrating performance and strength feature. Therefore, it has excellent filtration, filter impedance, mechanical strength, abrasive resistance, heat resistance and processability. The comprehensive performance is extremely better than sintered metal powder, ceramics, fibers, filter cloth, filter paper and other types of filtration material.

Where to use Sintered stainless steel mesh filters ?

Sintered stainless steel mesh filters are used as a machine component. One of the advantages is that they can apply to many industries and products. Such as the filtration of food and pharmaceutical industry especially for the pharmaceutical equipment of two in one or three in one. It plays an important role although it just a small machine component. One of their advantages is that it can filter many kinds of impurities, such as gas, dust, particles and so on.

HENGKO sintered disc filter consists of a highly uniform and interconnection hole net. These hole nets can capture solid particles in gas and liquid due to their winding path. 316L stainless steel can bear 750°F (399°C) oxidation and 900°F (482°C) temperature in a restore environment. Those filters can be washed in other ways, such as sonic cleaning and backwash.

Main Features of Sintered stainless steel mesh filters

Product feature of HENGKO stainless steel mesh filter series

1. High strength: It has high mechanical strength and compressive strength

2. High precision: Uniform surface filtration performance can be achieved at the filtration precision of 1~300 microns

3. Heat resistance: Can be used for continuous filtration from -200℃ to 500℃

4. Cleanability : cleaning is very simple due to the use of counterflow cleaning effect of the surface filter structure

HENGKO is the main supplier of the micro-sintered stainless steel filters and high-temperature porous metal filters globally.

We have many kinds of sizes, specifications and types product for your choose, multi process and complicated filtering products also can be customized as your requirement.

Post time: Aug-14-2020