From my years of experience in the industrial filtration sector, I have come to appreciate the extraordinary capacity and durability of Multilayer Sintered Stainless Steel Filter Meshes. These filters are like silent heroes, working tirelessly in a myriad of applications, ranging from the petrochemical industry to the food and beverage sector, even to our homes' water filtration systems. When it comes to the task of separating unwanted particles from your desired output, nothing does it better than these filters.

Now, you may wonder, "What makes these filters so unique and effective?"

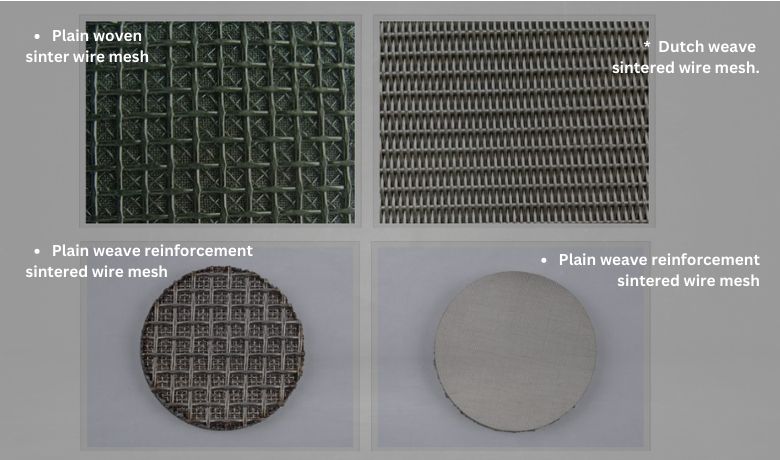

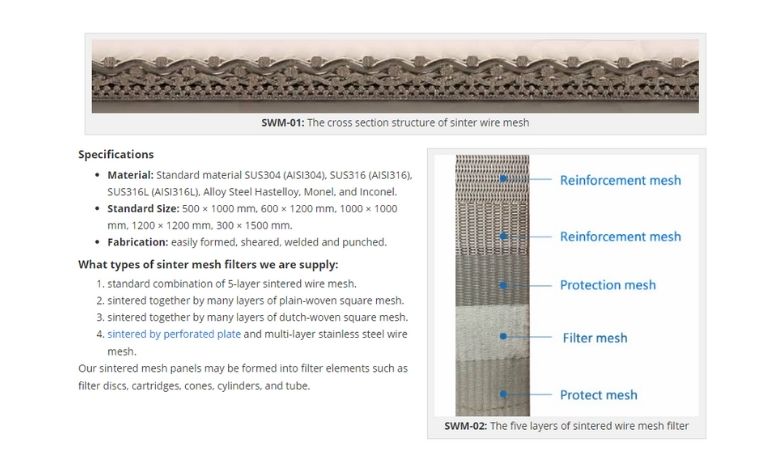

The answer lies in their exceptional structure, material, and manufacturing process. As the name implies, Multilayer Sintered Stainless Steel Filter Meshes are made of multiple layers of stainless steel mesh, undergoing a particular process known as sintering. This technique, as complex as it sounds, gives the filter meshes their distinguishing features that set them apart in the world of filtration technology.

The result is a filter mesh that not only excels in filtering efficiency but is also sturdy enough to withstand high pressures and temperatures. They are also lauded for their corrosion resistance and long lifespan - all of which I have personally experienced and will share more about in this blog post.

So, whether you're a process engineer looking for an upgrade in your filtration system, or simply an enthusiast eager to understand more about this technology, buckle up! We're about to take an in-depth journey into the world of Multilayer Sintered Stainless Steel Filter Meshes.

What is Filter Mesh ?

The world of filtration technology may seem complex and overwhelming at first glance, but at its core, it revolves around a simple, vital concept: separating unwanted materials from our desired output, whether it's clean water, purified air, or a specific chemical compound. To achieve this, we employ a crucial component known as a filter mesh.

So, what exactly is a filter mesh?

Simply put, a filter mesh is a precisely engineered sieving medium that allows certain substances to pass through while trapping others based on their size and shape. Imagine it as a vigilant gatekeeper, only allowing the approved substances to get through. It's the very cornerstone of many filtration systems, ensuring that we get the pure, uncontaminated results that we require.

Filter meshes are created from a broad range of materials, but one that stands out for its superiority in many regards is stainless steel. A stainless steel mesh is highly regarded for its durability, resistance to rust, and ability to withstand high pressures and temperatures. These properties make it an excellent choice for various demanding applications, from industrial processes to scientific research and even food and beverage production.

However, not all stainless steel filter meshes are created equal. Among the different types, the Multilayer Sintered Stainless Steel Filter Mesh has earned its place at the forefront due to its superior performance and adaptability. It owes these remarkable traits to the sintering process, which we will delve into in the next section.

Understanding Pore Size and Distribution

As we venture further into our exploration of the Multilayer Sintered Stainless Steel Filter Mesh, it becomes increasingly evident that this technological marvel's real magic lies in its minutiae. One such critical aspect is the pore size and distribution, a seemingly subtle characteristic with profound implications on the mesh's filtration efficiency.

Imagine walking through a maze: the size of the paths and their arrangement will determine how easily and quickly you can navigate through it. Similarly, in the realm of filtration, pore size and distribution in the mesh are akin to the labyrinth's layout, determining which particles pass through and which are trapped.

In a Multilayer Sintered Stainless Steel Filter Mesh, the pore size isn't a haphazard attribute but a carefully calibrated feature. The sintering process allows for precise control over the size of these pores, yielding a filter that can be tailored to specific filtration needs. Want to capture larger contaminants while allowing smaller particles to pass? Opt for a mesh with larger pores. Need to trap micro-sized particles? A finer mesh is your answer.

However, pore size is just one half of the equation. Equally important is the distribution of these pores across the mesh. A homogenous distribution ensures consistent filtration performance throughout the mesh, enhancing the filter's overall efficiency. Thanks to the sintering process, the Multilayer Sintered Stainless Steel Filter Mesh boasts a uniform pore distribution, ensuring optimal and consistent filtration at all times.

In essence, the precise control over pore size and distribution translates into customizable filtration performance, allowing the Multilayer Sintered Stainless Steel Filter Mesh to cater to a diverse range of filtration requirements. It's an example of how even the smallest details can have the most significant impact, proving once again that in the world of engineering, there's no such thing as an insignificant attribute.

Applications of Multilayer Sintered Stainless Steel Filter Mesh

Having navigated the technical complexities of the Multilayer Sintered Stainless Steel Filter Mesh, it is fitting to turn our attention to its practical applications. Where does this marvel of engineering fit in the grand scheme of industry and technology? The answer is astonishingly diverse, given the filter's robustness, precision, and durability.

A mainstay in the petrochemical industry, these filters are the guardians of purity in pipelines, processing plants, and refineries. Their ability to withstand extreme temperatures and resist corrosive substances makes them ideal for this harsh and demanding environment. The meticulous filtration they provide ensures the quality of fuels, lubricants, and other chemical compounds, thereby supporting the backbone of our global energy supply.

In the pharmaceutical sector, where the stakes of purity and contamination are life and death, these filters prove invaluable. They serve critical roles in processes such as air sterilization, particle removal in intravenous solutions, and even in the production of medicines. In this realm, their high precision and reliability are not just conveniences; they are absolute necessities.

Beyond these sectors, the Multilayer Sintered Stainless Steel Filter Mesh also finds significant usage in food and beverage production, water treatment plants, and automotive industry. They are instrumental in ensuring our drinking water is clean, our food is safe, and our cars run efficiently.

In sum, these filters are ubiquitous yet often unseen, quietly ensuring the smooth operation of many industries. Whether purifying crude oil into gasoline or filtering air in a pharmaceutical cleanroom, the Multilayer Sintered Stainless Steel Filter Mesh is a testament to how a product, born out of metallurgical brilliance and engineering precision, can make profound impacts in our daily lives.

The Benefits of Choosing Multilayer Sintered Stainless Steel Filter Mesh

As we approach the end of our exploration into the realm of the Multilayer Sintered Stainless Steel Filter Mesh, it is worth reflecting on why this particular product stands head and shoulders above its peers. What are the unique benefits that make it the preferred choice across diverse industries and applications?

1. Superior Filtration Performance:

Thanks to the sintering process and multi-layered design, this mesh offers unmatched filtration efficiency. It ensures a high precision filtering experience, capable of sieving out particles of varied sizes depending on its calibrated pore size.

2. Enhanced Durability:

The process of sintering fortifies the mesh's structure, making it incredibly robust. It can withstand high pressures, resist corrosion, and endure extreme temperatures, ensuring longevity in even the most demanding operational conditions.

3. Customizable Pore Sizes:

With the ability to control pore size and distribution, this filter mesh offers the ultimate in customization. Whether it's for sieving large debris or trapping microscopic contaminants, there's a Multilayer Sintered Stainless Steel Filter Mesh to suit the task.

4. Easy Maintenance:

Despite its sophisticated design and superior performance, this mesh is surprisingly easy to clean and maintain. Its robust structure can withstand backwashing or cleaning with chemicals, ensuring that it can be reused over a long period, thereby reducing replacement costs.

5. Broad Application Scope:

As we've seen, this mesh's applications span across numerous industries. Whether it's in the demanding conditions of a petrochemical plant or the stringent cleanliness requirements of a pharmaceutical lab, this filter mesh has proven its worth.

In conclusion, the Multilayer Sintered Stainless Steel Filter Mesh offers a blend of superior performance, durability, and flexibility, making it an outstanding choice for a broad spectrum of filtration applications. It is an investment in reliability and efficiency, a testament to the power of engineering and metallurgy to improve our lives and industries.

Selecting the Right Multilayer Sintered Stainless Steel Filter Mesh for Your Needs

Choosing the right Multilayer Sintered Stainless Steel Filter Mesh can seem like a daunting task given its various specifications and the range of applications it caters to. However, understanding your specific requirements and aligning them with the mesh's capabilities can simplify the selection process.

1. Understand Your Filtration Needs:

The first step in selecting the right mesh is understanding the particle size you need to filter. If you're dealing with larger particles, a mesh with larger pore size may suffice. For filtering out smaller particles, opt for a mesh with smaller pores.

2. Consider the Operating Conditions:

The operational environment plays a crucial role in selecting the right mesh. If you expect the filter to withstand high temperatures or corrosive substances, the Multilayer Sintered Stainless Steel Filter Mesh proves to be a reliable choice due to its durability and resistance to corrosion.

3. Evaluate the Flow Rate:

Another factor to consider is the fluid or gas flow rate in your process. A higher flow rate might require a filter with larger pores to prevent clogging and maintain efficiency, while a slower flow rate may work well with a finer mesh.

4. Assess the Maintenance Routine:

Consider how often you can afford to clean or replace your filters. The Multilayer Sintered Stainless Steel Filter Mesh is notably easy to maintain and clean, offering a long lifespan, which can significantly reduce the total operational costs.

5. Seek Expert Advice:

Finally, it's always a good idea to consult with a filtration expert or the mesh manufacturer. They can provide valuable insights and recommendations based on their expertise and your specific requirements.

In essence, selecting the right Multilayer Sintered Stainless Steel Filter Mesh involves a careful consideration of your filtration needs, operating conditions, and maintenance capabilities. This careful selection ensures optimal filtration performance and operational efficiency.

Frequently Asked Questions

1. What makes Multilayer Sintered Stainless Steel Filter Mesh different from regular stainless steel mesh?

The Multilayer Sintered Stainless Steel Filter Mesh is not just a product, but a symbol of meticulous engineering and design. The fundamental difference lies in its structure and manufacturing process. Unlike a regular stainless steel mesh that is woven, this mesh comprises multiple layers of stainless steel wire mesh that are heat-treated in a process called sintering. This results in a robust and stable structure that offers superior filtration efficiency, precise control over pore sizes, and excellent resistance to high temperatures and corrosion. Essentially, it's the sophistication and customization that the sintering process allows that sets it apart from a regular stainless steel mesh.

2. Can the Multilayer Sintered Stainless Steel Filter Mesh be customized to my specific needs?

Absolutely! One of the great advantages of the Multilayer Sintered Stainless Steel Filter Mesh is its customizability. During the sintering process, manufacturers can control the size of the pores, enabling the production of meshes tailored to filter out specific particle sizes. This means that regardless of your filtration needs, there's likely a Multilayer Sintered Stainless Steel Filter Mesh that can meet your requirements. It is advisable to consult with the manufacturer or a filtration expert to ensure you select the most suitable mesh for your application.

3. How do I clean and maintain the Multilayer Sintered Stainless Steel Filter Mesh?

Despite its complex structure and superior performance, the Multilayer Sintered Stainless Steel Filter Mesh is relatively easy to maintain. It can be cleaned through backwashing, ultrasonic cleaning, or even using specific chemicals, depending on the type of contaminants. One of the significant benefits of this mesh is its durability; with proper maintenance, it can serve for an extended period, making it a cost-effective choice in the long run. However, always refer to the manufacturer's instructions or consult a professional to ensure the correct maintenance routine.

4. Can the Multilayer Sintered Stainless Steel Filter Mesh withstand high temperatures and pressures?

Indeed, it can. The process of sintering not only bonds the layers of mesh together but also fortifies its structure. This results in a filter mesh that can withstand high temperatures and pressures, making it an ideal choice for demanding operational environments such as in the petrochemical industry or any high-temperature processing plants. However, it's always crucial to check the manufacturer's specifications to ensure the mesh can withstand the specific conditions of your application.

5. Where can I use Multilayer Sintered Stainless Steel Filter Mesh?

The applications of Multilayer Sintered Stainless Steel Filter Mesh are wide and diverse. Thanks to its robustness, precision, and durability, it can be used in several industries. From the petrochemical industry, where it helps purify fuels, to the pharmaceutical sector, where it assists in sterilizing air or filtering solutions, the mesh proves its worth. Additionally, it's also used in water treatment plants, food and beverage production, and the automotive industry. In essence, wherever there's a need for reliable and efficient filtration, the Multilayer Sintered Stainless Steel Filter Mesh can likely serve.

Get in Touch Today!

If you're captivated by the potential of the Multilayer Sintered Stainless Steel Filter Mesh and eager to understand how it can transform your filtration processes, there's no better time than now to explore. Contact HENGKO, the experts in sintered filtration solutions, to guide you on this journey.

HENGKO is a leading provider of top-quality, customizable filtration solutions. We pride ourselves on our expertise, quality products, and commitment to customer satisfaction. Our team is ready to help you identify the best Multilayer Sintered Stainless Steel Filter Mesh for your specific needs, ensuring optimal performance and efficiency.

If you have further queries, need a consultation, or are ready to place an order, reach out to us directly at ka@hengko.com. Embrace the power of superior filtration and witness the transformation in your processes with HENGKO.

Connect with us today. Your journey towards superior filtration begins with HENGKO.

Post time: Jun-16-2023