What are Stainless Steel Gas Filters?

Stainless Steel Gas Filters and Ultra-High Gas Purifier Systems play a crucial role in various industries, including pharmaceutical, biotech, semiconductor manufacturing, solar cell production, and food and beverage production. These systems purify gases to very high levels and deliver them safely to their destinations. This blog post will explore how these systems work, their advantages, and their various applications.

The high-purity gas system filter mainly filters the impurities and pollutants contained in the high-purity gas inside the system. Its principle is to filter out the particles in the gas through the diffusion and interception mechanism. If there are any impurities in the ultra-pure gas, it will cause the quality of the gas to decrease and affect the purity of the gas.

Ultra-High Purity Gases are single gases; such as Oxygen, Hydrogen, Nitrogen, Argon, Helium, Oxygen, Carbon Dioxide, and in other Special Gases, with a purity of equal or greater than 99.9995% meaning that 0.0005% of the gas is comprised of other gases (impurities).

HENGKO Ultra-High Purity Gas Filters are usually installed in the part downstream of valves and accessories and before air intake. Metal particles fall off due to vibration effects or strong airflow impact inside the air supply system, which can easily bring particle pollutants into the gas. Therefore, ultra-high purity gas filters are required.

HENGKO Semiconductor High Purity Filters can perform effective and precise filtration of ultra-pure gas and can meet the requirements of working conditions through multi-stage processing. The product is integrated and seamlessly combined with no welding parts, which is suitable for gas and liquid filtration under high-pressure conditions.

A. How Stainless Steel Gas Filters work

Stainless Steel Gas Filters remove impurities, such as particulates and moisture, from gases. These filters use a porous stainless steel membrane to trap impurities while allowing the purified gas to pass through. The membrane is typically made of a sintered stainless steel powder, which is compressed to form a porous filter element.

B. Advantages of using Stainless Steel Gas Filters

One of the main advantages of using stainless steel gas filters is their durability and corrosion resistance. The stainless steel membrane is resistant to corrosion and can withstand high temperatures, making it ideal for industrial gas filtration. Additionally, these filters have a low-pressure drop, require less energy, and can be used in systems with limited space.

1. Durability and corrosion resistance

2. High-temperature tolerance

3. Low-pressure drop

C. Applications of Stainless Steel Gas Filters

1. Industrial gas filtration

2. Pharmaceutical and biotech industries

3. Food and beverage industry

Ultra-high purity gas systems are commonly used in semiconductor manufacturing, where they are used to purify gases used in the production of semiconductors. They are also used in solar cell production, where they are used to purify gases used in the production of solar cells. Additionally, they are used in medical equipment sterilization, where they are used to purify gases used in sterilization processes.

HENGKO High-pressure UHP gas filters are constructed entirely from 316L stainless steel, either with Viton or PTFE seals. Suitable for both liquids and gases, these filters are ideal for high flow corrosive applications with 1" to 2" line sizes. A variety of flange connections are also available

Ultra-pure gas is used in almost every process in the semiconductor industry, and the quality of the device is closely related to the purity of the ultra-pure gas. Therefore, it is important to pay attention to the filtration and purification of ultra-pure gas. Choosing an ultra-pure gas filter with excellent quality can help effectively remove falling particles and protect the purity of ultra-pure gas to avoid engineering losses and damage.

Main Features of Ultra-High Gas Purifier System

The Ultra-High Gas Purifier System is designed to effectively remove impurities from various gases. While the specific features may vary based on the manufacturer and the model of the purifier system, they generally include the following key characteristics:

-

High Efficiency: Ultra-High Gas Purifier Systems are built for maximum efficiency in the removal of contaminants. They are capable of purifying gases to ultra-high purity levels, often removing impurities down to parts-per-billion (ppb) levels or even lower.

-

Broad Spectrum of Gas Handling: These systems are typically designed to purify a wide range of gases. This includes, but is not limited to, inert gases (like nitrogen or argon), hydride gases, halogen gases, and reactive gases.

-

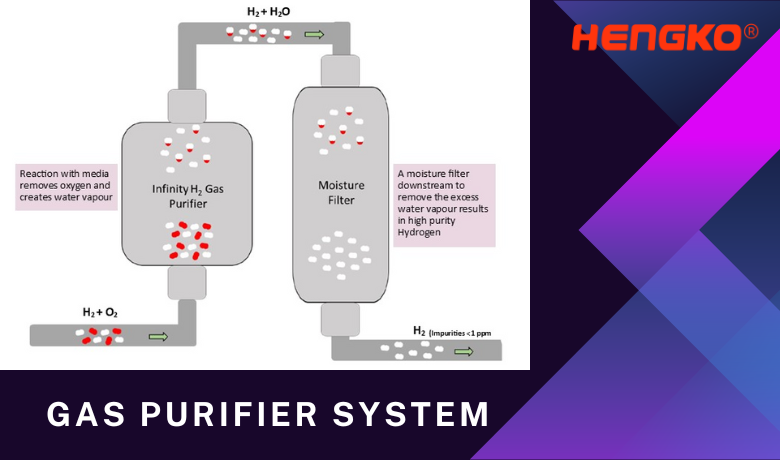

Multiple Stages of Purification: To achieve ultra-high purity, these systems often utilize multiple stages of purification. This can include processes like adsorption, chemical reaction, and filtration, all working in harmony to effectively remove different types of impurities.

-

Robust and Durable Design: Given the nature of their work, these purifiers are often built to withstand harsh operating conditions and high pressures. They are generally made from materials that resist corrosion and wear.

-

Automatic Monitoring and Control: Many of these systems come with integrated sensors and control systems for automatic monitoring of the purification process. This allows for continuous operation and immediate response to any changes in system conditions.

-

Low Maintenance: The purifier systems are designed for long-term use with minimal maintenance. Components are typically easy to replace when needed.

-

Safety Features: Safety is a critical aspect in the design of these systems. Features might include overpressure protection, alarms for system failure or when maintenance is required, and safety measures for handling hazardous gases.

-

Environmentally Friendly: Many ultra-high gas purifier systems are designed to minimize environmental impact, for instance, by reducing waste or making efficient use of energy.

Keep in mind that the features can vary based on the specific requirements of the application or industry. Always consult with the manufacturer or supplier for the best system to meet your needs.

FAQ

1. Q: What type of gases can the Ultra-High Gas Purifier System handle?

A: The Ultra-High Gas Purifier System is designed to handle a broad spectrum of gases. This includes, but is not limited to, inert gases such as nitrogen and argon, hydride gases, halogen gases, and reactive gases. The specific capability of a purifier system to handle certain gases depends on its design, the materials used in its construction, and the purification technologies it employs. Before using a gas purifier system, it is important to verify with the manufacturer or supplier whether the specific gas you intend to purify is compatible with the system.

2. Q: How pure can the gas get with an Ultra-High Gas Purifier System?

A: Ultra-High Gas Purifier Systems are designed to achieve ultra-high levels of gas purity. These systems can often reduce impurity levels to parts-per-billion (ppb) levels, and in some cases, even to parts-per-trillion (ppt) levels. The exact level of purity achieved can depend on several factors, including the initial impurity level of the gas, the specific type of impurities, the purification technologies used in the system, and the operational parameters of the purification process.

3. Q: How is the purification process monitored?

A: Many Ultra-High Gas Purifier Systems are equipped with automatic monitoring and control systems. These can include sensors that monitor various parameters such as pressure, temperature, and flow rate, as well as analyzers that can detect specific impurities. The data from these sensors and analyzers can be used to control the purification process automatically, ensuring that the desired level of purity is maintained consistently. Furthermore, advanced systems may also have remote monitoring capabilities, allowing operators to monitor and control the system from a distance.

4. Q: What maintenance does an Ultra-High Gas Purifier System require?

A: Although Ultra-High Gas Purifier Systems are designed for long-term use with minimal maintenance, some maintenance is typically required. This can include routine inspection of the system, replacement of consumable components (such as filters or absorbents), and occasional cleaning or servicing of the system. The specific maintenance requirements can vary depending on the design of the system and the conditions of use. The manufacturer or supplier should provide detailed maintenance instructions.

5. Q: What safety features do Ultra-High Gas Purifier Systems have?

A: Safety is a key consideration in the design of Ultra-High Gas Purifier Systems. Common safety features can include overpressure protection, alarms for system failure or when maintenance is required, and measures to safely handle hazardous gases. Some systems may also have features to prevent contamination of the purified gas, such as one-way flow valves or purifiers that are designed to shut down automatically in the event of a failure. As with any industrial equipment, it is important to follow all safety guidelines and procedures when operating a gas purifier system.

Conclusion

In conclusion, Stainless Steel Gas Filters and Ultra-High Purity Gas Systems are essential tools in various industries, allowing for the safe and efficient delivery of high-purity gases. Stainless Steel Gas Filters are known for their durability and corrosion resistance, while ultra-high purity gas systems provide the highest possible gas purity, safety, and contamination control. With advancements in technology, we can expect these systems to continue to improve and play an even more crucial role in various industries in the future.

Contact us by email ka@hengko.com if interested to OEM your own Stainless Steel Gas Filter

we will send back to you asap within 24-Hours.

Post time: Dec-06-2021