1.What Is a Gas Sparger?

A micro sparger is a precision gas diffusion device designed to create very fine bubbles in a liquid. It typically uses porous materials such as sintered stainless steel or ceramic—these are examples of sintered porous materials. The tiny pores in these materials allow gas to pass through evenly and form micro-sized bubbles. These tiny bubbles greatly increase the surface area of contact between gas and liquid, making gas transfer faster and more efficient.

1.1Why It’s Critical for Efficient Gas–Liquid Transfer

In many chemical and biological processes, efficient gas–liquid mixing determines reaction speed, yield, and product quality. Compared with ordinary diffusers, micro spargers produce uniform microbubbles that:

Enhance gas dissolution and mass transfer ratesReduce gas waste and improve energy efficiency *Maintain stable flow and pressure performance over long operation times

In short, a well-designed micro sparger can significantly improve process efficiency and lower operating costs.

1.2 Key Industries Using Micro Spargers

Micro spargers are widely used wherever precise gas introduction is required, including:

Biotechnology & Pharmaceutical:* for aeration in bioreactors, fermentation, and cell culture* Chemical Processing: in hydrogenation, ozonation, or CO₂ dissolution systems *Food & Beverage: for brewing, carbonation, and water treatment\ *Environmental & Energy Fields: for wastewater aeration, flue gas treatment, or gas sampling

2. Introduction to Gas Transfer

Gas transfer is crucial in industries like biotechnology, pharmaceuticals, chemical manufacturing, and wastewater treatment. It involves introducing gases—such as oxygen, air, or carbon dioxide—into liquids to maximize gas–liquid contact, which drives key biological and chemical reactions.

2.1 Why It Matters

Efficient gas transfer is essential for:

*Promoting cell growth

*Supporting fermentation

*Improving product yields

The volumetric mass transfer coefficient (kLa) measures efficiency

—a higher kLa means faster gas absorption, reduced gas usage, and better performance.

2.2 Micro Spargers vs Traditional Methods

Traditional spargers produce large bubbles with limited surface area, reducing efficiency. Micro spargers, made from porous materials like sintered stainless steel, create tiny bubbles (<100 µm) that:

*Increase gas–liquid contact

*Boost mass transfer

*Improve reactor yields

2.3 Benefits of Micro Spargers

*Higher gas transfer rates:

100–400% more efficient than conventional spargers

*Lower gas consumption:

Efficient dissolution saves costs

*Versatility:

Bubble sizes from 2–15 µm for lab, pilot, or industrial use

*Better performance:

Faster cell growth, higher yields, and reliable results

Conclusion

Micro spargers are a highly effective solution for enhancing gas transfer in bioreactors, fermentation, and water treatment.

By creating tiny, uniform bubbles, they maximize efficiency, reduce gas usage, and improve overall process performance.

3. How Micro Spargers Work

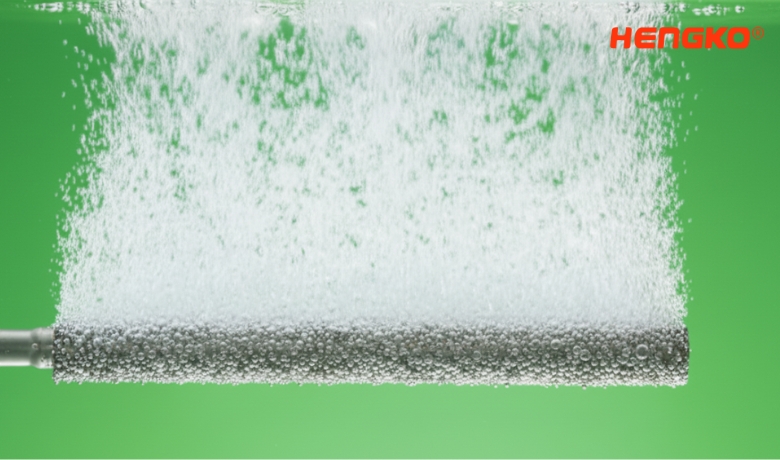

3.1 The Principle of Microbubble Formation

A micro sparger operates by forcing gas through a porous medium — usually made from sintered stainless steel, titanium, or ceramic.

When gas passes through these tiny, evenly distributed pores, it breaks into micro-sized bubbles (typically <100 microns).

These microbubbles provide a large surface area-to-volume ratio, allowing gases like oxygen, nitrogen, hydrogen, or carbon dioxide to dissolve quickly and uniformly in the liquid phase.

In short, the smaller the bubbles, the faster and more efficient the gas transfer.

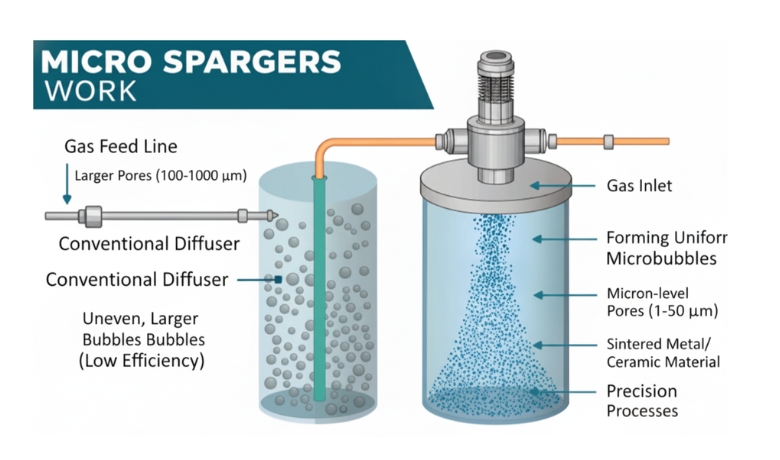

3.2 Difference Between a Micro Sparger and a Diffuser

Although both devices introduce gas into liquid, their design and performance are quite different:

|

Feature |

Micro Sparger |

Conventional Diffuser |

|---|---|---|

|

Pore Size |

Micron-level (1–50 µm) |

Larger pores (100–1000 µm) |

|

Bubble Size |

Uniform microbubbles |

Uneven, larger bubbles |

|

Material |

Sintered metal or ceramic |

Plastic, rubber, or stone |

|

Gas Efficiency |

High dissolution rate |

Lower efficiency |

|

Applications |

Precise industrial processes |

General aeration or mixing |

So while a diffuser is suitable for simple aeration, a micro sparger is designed for precision processes

where consistent bubble size and high gas utilization are critical

— such as bioreactors, fermentation, or chemical reactions.

3.3 How Bubble Size Impacts Gas Absorption and Process Yield

Bubble size directly determines how effectively gas transfers into a liquid.

Smaller bubbles = more surface area*, which increases contact time between gas and liquid.* Microbubbles rise more slowly, staying in the liquid longer to achieve better dissolution. *This leads to higher reaction efficiency, improved product yield, and reduced gas waste.

Micro spargers also promote cell growth and provide agitation, both of which contribute to higher process yields.

That’s why modern OEM systems increasingly replace traditional diffusers with micro spargers — they simply deliver superior gas–liquid mass transfer performance.

4. Common Applications of Micro Spargers

|

Application Area |

Process / Purpose |

Key Benefits of Using Micro Sparger |

Typical Gases Used |

Recommended Material |

|---|---|---|---|---|

|

Bioreactors & Fermenters |

Oxygen transfer for cell culture and fermentation |

• Higher dissolved oxygen (DO) levels\ • Uniform microbubble distribution\ • Porous medium designed to generate bubble sizes optimized for efficient gas transfer\ • Micro spargers create very small bubbles and small bubbles, enhancing gas–liquid contact and dissolution\ • Reduced foaming and shear stress |

O₂, Air |

Sintered Stainless Steel 316L / Titanium |

|

Chemical Hydrogenation & Ozonation |

Gas–liquid mixing for reactions such as hydrogenation, ozonation, CO₂ dissolution |

• Enhanced mass transfer and reaction yield\ • Uniform gas distribution\ • Stable under high pressure & temperature |

H₂, O₃, CO₂ |

Stainless Steel / Titanium / PTFE |

|

Wastewater Aeration & Environmental Treatment |

Oxygen or ozone introduction for pollutant oxidation and biological treatment |

• High oxygen transfer efficiency (OTE)\ • Lower energy cost\ • Less sludge and odor formation |

O₂, O₃, Air |

Stainless Steel / Ceramic |

|

Brewing & Carbonation |

Gas injection for carbonation, deoxygenation, or flavor control |

• Consistent carbonation\ • Fast absorption, no foaming\ • Hygienic and easy to clean |

CO₂, N₂ |

Stainless Steel 316L (Sanitary Grade) |

5. Design Factors to Consider

Choosing the right micro sparger design is essential to achieve stable gas flow, efficient mass transfer, and long service life. Below are the key factors engineers and OEM users should evaluate before selection or customization.

|

Design Factor |

Description |

Key Considerations / Best Practices |

|---|---|---|

|

Material Selection |

Micro spargers are commonly made from 316L stainless steel, PTFE, or ceramic. The material affects durability, corrosion resistance, and cleanability. |

• 316L SS – excellent mechanical strength and corrosion resistance, ideal for biotech, brewing, and chemical use.\ • PTFE (Teflon) – suitable for aggressive chemicals and non-stick surfaces.\ • Ceramic – good for high-temperature or ozone applications, but more fragile. |

|

Pore Size & Flow Rate Balance |

The pore size determines bubble diameter and gas transfer efficiency. Smaller pores create finer bubbles but require higher gas pressure. |

• For biological and precision applications: 1–10 µm pores.\ • For general aeration: 10–50 µm pores.\ • Balance gas pressure and flow to prevent clogging or excessive backpressure. |

|

Connector Types & Installation |

Proper connection ensures easy integration into process lines and leak-free operation. |

• Common connections: VCR, NPT, Tri-Clamp, or custom OEM fittings.\ • Consider installation method (threaded, welded, or sanitary clamp).\ • Ensure tight sealing and easy disassembly for cleaning. |

|

Temperature, Pressure & Chemical Compatibility |

Each sparger must withstand its working environment without deformation or corrosion. |

• Verify maximum operating temperature and pressure ratings.\ • Match material to gas and liquid chemistry (e.g., ozone, acid, solvent).\ • For high-pressure hydrogenation or ozone use, choose titanium or 316L spargers. |

|

Bioreactors & Fermenters |

Micro spargers are widely used in bioreactor application and fermenter setups to optimize gas transfer, aeration, and fermentation processes. They can be tailored to support specific organism requirements and specific media types, enhancing mass transfer and cell growth. |

• Select sparger pore size and material based on the organism and specific media used in the process.\ • Ensure compatibility with bioreactor or fermenter design.\ • Consider cleaning and sterilization requirements. |

Micro spargers can also increase benchtop laboratory bioreactor performance by optimizing gas transfer for different organisms and specific media.

Tips

So if you also have project need to custome micro bubble sparger, so when designing or sourcing an OEM micro sparger,

always provide your supplier with key operating parameters — including gas type, flow rate, liquid medium,

operating pressure, and temperature range.

By specifying these details, you enable a micro sparger tip optimized for bubble size, media, and organism requirements, ensuring the sparger is tailored for your bioprocess needs.

This ensures the sparger is optimized for performance, durability, and safety in your specific application.

6. OEM Customization Options

For industrial and specialized applications, off-the-shelf micro spargers may not meet all process requirements. OEM micro spargers offer custom solutions designed to maximize efficiency, reliability, and integration with your equipment.

|

Customization Area |

Description |

Benefits / Considerations |

|---|---|---|

|

Tailored Pore Sizes & Geometries |

Micro spargers can be manufactured with specific pore sizes, shapes, and distributions to optimize bubble formation for your process. |

• Achieve the desired bubble diameter for maximum gas–liquid transfer.• Control gas flow uniformity and minimize dead zones.• Adapt to high-viscosity or foaming liquids. |

|

Integration with Proprietary Reactor Systems |

OEM spargers can be designed to fit specific reactor or vessel configurations, ensuring seamless installation. |

• Custom connectors and mounting options.• Optimized placement for even gas distribution.• Compatible with existing equipment without extensive modification. |

|

Performance Testing & Validation |

Spargers can be tested under real or simulated conditions before delivery to ensure they meet performance targets. |

• Confirm flow rate, bubble size, and mass transfer efficiency.• Reduce risk of operational issues after installation.• Ensure compliance with process requirements and safety standards. |

|

Traceability & Documentation |

For regulated industries, micro spargers can be provided with full documentation and quality traceability. |

• Material certificates, test reports, and manufacturing records.• Compliance with GMP, ISO, or other industry standards.• Essential for biotech, pharmaceutical, and food applications. |

So When ordering an OEM micro sparger, also you can provide detailed process requirements to your supplier:

Gas type and flow rateLiquid type, viscosity, and temperature *Reactor or vessel dimensions *Regulatory requirements (if applicable)

This ensures the micro sparger is custom-engineered for maximum performance, efficiency, and compliance.

Companies such as Mott Corporation and Biotech Fluidics provide custom micro sparger solutions designed to enhance gas transfer and process efficiency in specialized applications.

7. Maintenance and Longevity

Proper maintenance ensures that micro spargers continue to perform efficiently and last for many years. Regular cleaning, monitoring, and preventive measures can prevent common issues like clogging, scaling, and corrosion.

|

Maintenance Area |

Description / Tips |

Best Practices |

|---|---|---|

|

Cleaning and Regeneration |

Over time, sparger pores can become blocked by deposits, biofilm, or particles. Cleaning restores optimal gas flow. |

• Flush with clean water or compatible solvent after each batch.• For metal spargers, consider mild acid or alkaline cleaning solutions if compatible with material.• Ultrasonic cleaning can help remove stubborn deposits without damaging pores. |

|

Common Issues |

Micro spargers may encounter clogging, scaling, or corrosion depending on process conditions. |

• Clogging – caused by particle buildup; prevent by filtering liquid or using pre-filters.• Scaling – mineral deposits in high-hardness water; periodic descaling recommended.• Corrosion – occurs if material is incompatible with gas or liquid; ensure proper material selection (e.g., 316L SS for most applications). |

|

Best Practices for Longevity |

Following simple operational guidelines extends the life of the sparger. |

• Operate within specified pressure, temperature, and chemical limits.• Inspect spargers regularly for signs of wear or blockage.• Maintain a preventive cleaning schedule based on usage frequency and process fluid characteristics.• Store spare spargers in a clean, dry environment to prevent contamination or corrosion. |

Implementing a regular maintenance schedule ensures consistent gas–liquid transfer efficiency,

reduces downtime, and extends the life of your micro spargers

— especially in biotech, chemical, and food processing applications.

8. Conclusion

Choosing the right micro sparger — whether off-the-shelf or custom OEM

— can make a significant difference in gas–liquid transfer efficiency, process yield, and operational cost savings.

Proper design, material selection, and maintenance ensure your system performs reliably across bioreactors,

chemical reactors, wastewater treatment, and beverage production.

If you are looking for a high-quality, custom micro sparger tailored to your specific application, our team can help.

We provide OEM design, tailored pore sizes, material selection, and full performance validation

to ensure your process achieves maximum efficiency.

Post time: Nov-10-2025