Compressed air systems are often used in industrial manufacturing processes for cooling, heating, equipment maintenance, and power tool operation.

Then Why Dew Point Measurement in Compressed Air is Very Important ?

Because In the production of compressed air, the inevitable byproduct is water vapor, which condenses on the air compressor system or additional process components.

Although a small amount of moisture may be present in compressed air systems, the accumulation of large amounts of condensation can damage sensitive

equipment and reduce the quality of finished products. In this regard, monitoring the compressed air dew point is crucial to ensure the service life of the machine and

standardization of product quality.

But Here Are 6 Points You Need to Know About Dew Point Measurement in Compressed Air, Hope It will be Helpful.

First, what is the dew point of compressed air system?

The dew point of an air compressor system is the temperature at which water vapor condenses into liquid at the same rate as evaporation.

At this temperature, the compressed air is completely saturated and can no longer hold water vapor. For industrial operators manufacturing with

compressed air systems, dew points must be continuously monitored to prevent instrument damage and minimize process contamination.

Second, Is dew point measured in degrees?

Use the dew point transmitter to measure the dew point temperature of compressed air in degrees Fahrenheit.

For most systems, the dew point temperature of the air remains in the range of 50°F to 94°F. At this temperature, water suspended in the air precipitates and begins to collect on compressor components.

If read accurately,the dew point sensors will allow the operator to implement different water removal methods and maintain the integrity of their machine.

Third, Why is dew point important in compressed air applications?

Maintaining moisture at a certain level is critical to maintaining the function of sensitive industrial equipment. If left unchecked, moisture from compressed air at its dew point can cause mechanical corrosion of metals, leading to costly system failures and maintenance outages.

In addition, excess moisture in compressed air supplied to industrial processes can adversely affect product quality. The buildup of water vapor can transfer impurities like dust and bacteria to sensitive food and drug manufacturing processes, making them unsafe to export and eat.

The adverse impact of moisture damage on air compressor systems is why all operators must strictly monitor water saturation in their air systems.

Fourth, Dew point and pressure relationship

There is an obvious relationship between the dew point at which compressed air reaches saturation and the pressure of the transmission pressure. For any gas, an increase in pressure results in a corresponding increase in dew point. A series of calculations and transformations are performed manually or using software that accurately predicts air dew points and helps the operator develop appropriate dehumidification protocols. The hand-held temperature and humidity meter of Hengko can automatically convert the detected temperature and humidity data into dew point value, which is convenient for real-time viewing.

Fifth, What is the difference between dew point and pressure dew point?

In practice, the terms "dew point" and "pressure dew point" are often used interchangeably. However, this alternative is not accurate. The dew point is the temperature at which the air reaches saturation at atmospheric pressure, while the pressure dew point is defined as the dew point of a gas measured at pressure above normal atmospheric pressure.

Sixth, How to Measure Dew Point in Compressed Air

Dew point of compressed air can be accurately measured using dew point instruments specially manufactured for this purpose.

1.) Instrument selection

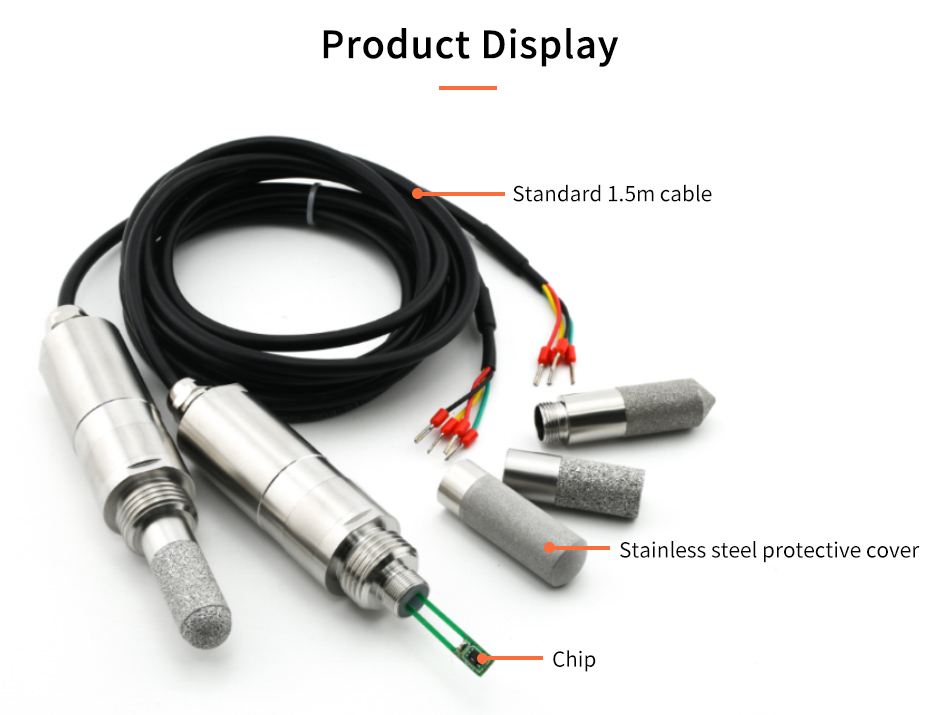

The first step in evaluating dew point is to select an appropriate dew point measurement instrument. To avoid measurement errors, the operator must purchase the equipment best suited to its air compression unit. Choose according to the dew point range you need to measure. If you need a dew point meter in the range of -60℃-60℃, you can choose HT-608 Digital Humidity and Temperature Meter, which has the advantages of high precision, accurate measurement and low power consumption. The compressed air dew point transmitter is compact and high pressure resistant, and can be installed in the pipeline or gas pipeline outlet for measurement.

2.) Understand the changes in the pressure characteristics of the instrument

Some dew point sensors are suitable for measuring water saturation at atmospheric pressure, while others deliver dew point readings more accurately at higher operating pressures. Again, you must select the right measuring device based on the pressure characteristics of the compressed air system to ensure the most accurate results.

3.) the correct sensor installation

Dew point sensor installation kit comes with specific instructions for proper installation. Following manufacturer's guidelines when installing dew point sensors will help ensure their optimum function.

4.) nitrogen dew point temperature

Due to its inertia, nitrogen can be used in a variety of industrial processes, including equipment flushing procedures. Gaseous nitrogen passing through the system or process will effectively remove water and oxygen without altering any critical chemical reactions. The dew point temperature of dried nitrogen is usually around -94°F.

Also You Can Send Us Email Directly As Follow : ka@hengko.com

We Will Send Back With 24-Hours, Thanks for Your Patient !

Send your message to us:

Post time: May-20-2022